Anticorrosive wear-resistant paint for magnesium alloy and preparation method thereof

An anti-corrosion and wear-resistant, magnesium alloy technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve problems such as defective anti-corrosion and wear resistance, complex coating formulations, equipment damage, etc., to improve safety and Long service life, high self-lubricating effect, effect of reducing friction and wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

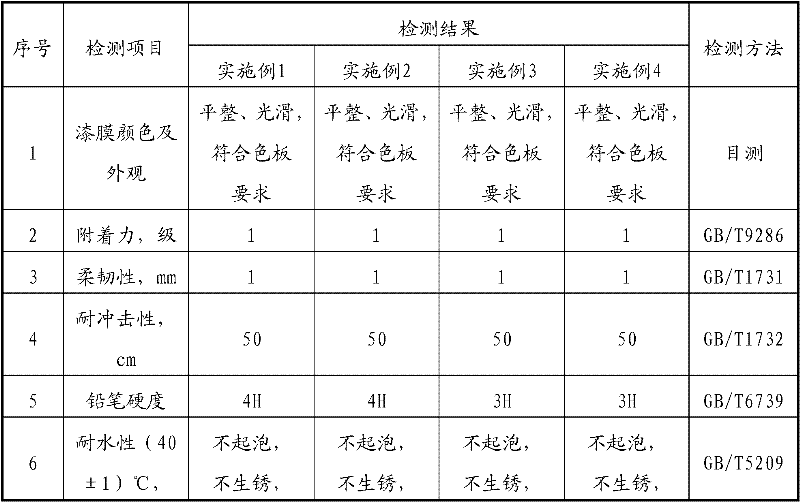

Examples

Embodiment 1

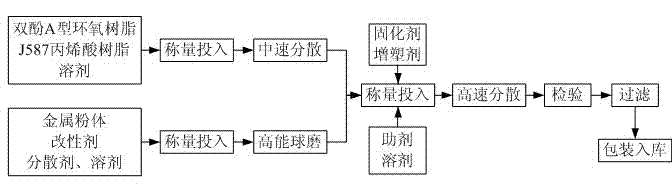

[0029] A kind of anticorrosion wear-resisting paint for magnesium alloy, it adopts following preparation method to make:

[0030] Modified epoxy resin liquid: inject 70% bisphenol A type epoxy resin, 20% J587 acrylic resin and 10% ethyl acetate into a stirring container to stir, grind and disperse, and the stirring speed is 600 rpm to 900 rpm / min, stirring and grinding for 1h to 2h to obtain a modified epoxy resin liquid.

[0031] Metal nanopolymer: 44% metal powder by weight percentage, wherein the metal powder is composed of 32% Ti, 45% Al 2 o 3 , 23%MoS 2 Composition, 18% polysiloxane, 12% ethanol, and 12% propyl acetate are added to a ball mill jar, and then liquid nitrogen and zirconium beads of different diameters and sizes are added, wherein the mass ratio of zirconium beads to metal powder is 8 : 1, zirconium beads are 1:3:7 according to the ratio of large, medium and small diameters, the volume of adding liquid nitrogen accounts for about 1 / 3 of the volume of the...

Embodiment 2

[0037] Embodiment 2: a kind of anticorrosion wear-resisting paint for magnesium alloy, it is by 50% modified epoxy resin liquid, 8% metal nano polymer, 12% polyamide resin 315, 4% soybean oil or rapeseed oil, 1% It is made of BYK306 leveling agent, BYK141 defoamer and 25% methyl isobutyl ketone in any proportion.

[0038] The modified epoxy resin liquid is made of 75% bisphenol A epoxy resin, 15% J587 acrylic resin, and 10% acetone; the metal nanopolymer is made of 42% metal powder, 20% polyaluminum ethyl Made of siloxane, 15% ethyl ketone, 23% ethanol, the metal powder is made of 40% Ti, 40% Al 2 o 3 and 20% MoS 2 composition.

[0039] Other content is the same as embodiment 1.

Embodiment 3

[0040] Embodiment 3: a kind of anticorrosion wear-resisting paint for magnesium alloy, it is by 55% modified epoxy resin liquid, 10% metal nano polymer, 6% polyamide resin 605, 2% FA type polysulfide rubber, 1% It is made of BYK354 leveling agent, BYK141 defoamer and 26% ethanol in any proportion.

[0041] The modified epoxy resin liquid is made of 80% bisphenol A epoxy resin, 10% J587 acrylic resin, and 10% acetone; the metal nanopolymer is made of 37% metal powder, 15% polyaluminum ethyl Made of siloxane, 10% ethyl ketone, 38% ethanol, of which the metal powder is 50% Ti, 35% Al 2 o 3 and 15% MoS 2 composition.

[0042] Other content is the same as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com