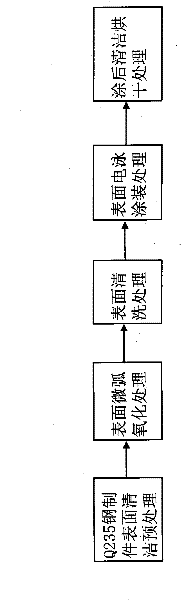

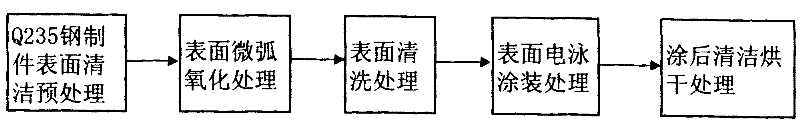

Microarc-oxidation electrophoretic-coating composite processing method of surface of Q 235 steel part

A technology of micro-arc oxidation and electrophoretic coating, applied in the direction of anodic oxidation, electrolytic coating, electrophoretic plating, etc., can solve the problems of complex electrolyte formula, complex process, small mass production, etc. The effect of high process efficiency and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The pre-treatment method of Q235 steel is to use No. 400 to No. 1200 water sandpaper to polish in sequence, and then use 20g / L NaOH, 15g / L NaOH 2 CO 3 , 1 drop of OP-10 emulsifier prepared by alkaline washing solution for degreasing and degreasing for 5 minutes, and then use 3% H 2 SO 4 , the activation solution prepared by 7% HCL was activated for 10 minutes, and then micro-arc oxidation was performed in a specific proportion of aluminate electrolyte at 35°C for 10 minutes, the termination voltage was 170V, the frequency was 172Hz, the base value time was 2.99, and the current density was 3A / dm 2 .

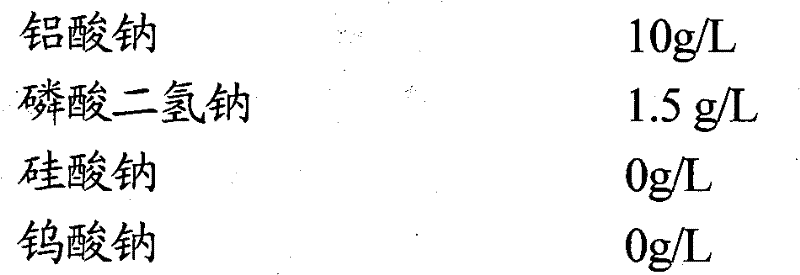

[0024] The specific ratio aluminate electrolyte consists of (weight content per unit volume):

[0025]

[0026] The Q235 steel after micro-arc oxidation was cleaned with tap water and distilled water. After cleaning in an ultrasonic cleaner for 8 minutes, it was transferred to HED-5000 red epoxy cathodic electrophoretic paint with a pH value of 5.90 for 3 seconds, st...

Embodiment 2

[0031] The pre-treatment method of Q235 steel is to use No. 400 to No. 1200 water sandpaper to polish sequentially, using 15g / L NaOH, 25g / L NaOH 2 CO 3 , 4 drops of OP-10 emulsifier made of alkali washing solution for degreasing and degreasing for 5 minutes, and then use 8% H 2 SO 4 , the activation solution prepared by 12% HCL was activated for 13 minutes, and then micro-arc oxidation was performed in a specific proportion of aluminate electrolyte at 25°C for 30 minutes, the termination voltage was 207V, the frequency was 172Hz, the base value time was 2.99, and the current density was 2A / dm 2 .

[0032] The specific ratio aluminate electrolyte consists of (weight content per unit volume):

[0033]

[0034] After micro-arc oxidation, the Q235 steel was cleaned with tap water and distilled water, put into an ultrasonic cleaner for 8 minutes, then transferred to HED-5000 sky blue epoxy cathodic electrophoretic paint with a pH value of 5.90 for 10 seconds, stirred for 8 se...

Embodiment 3

[0039] The pre-treatment method of Q235 steel is to use No. 400 to No. 1200 water sandpaper to polish sequentially, using 30g / LNaOH, 20g / L NaOH 2 CO 3 , 2 drops of OP-10 emulsifier made of alkali washing solution to degrease and degrease for 10 minutes, and then use 6.5% H 2 SO 4, the activation solution prepared by 8% HCL was activated for 10 minutes, and then micro-arc oxidation was performed in a specific ratio of aluminate electrolyte at 25°C for 60 minutes, the termination voltage was 246V, the frequency was 172Hz, the base value time was 2.99, and the current density was 1.5A / dm 2 .

[0040] The specific ratio aluminate electrolyte consists of (weight content per unit volume):

[0041]

[0042] The Q235 steel after micro-arc oxidation was cleaned with tap water and distilled water, put it in an ultrasonic cleaner for 8 minutes, then transferred to HED-5000 purple epoxy cathodic electrophoretic paint with a pH value of 5.90 for 20 seconds, stirred for 10 seconds, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com