Low-pressure casting method for abrasion-resistant aluminum alloy bicycle accessory

A low-pressure casting, aluminum alloy technology, applied in the field of aluminum alloy production and deep processing, to achieve the effect of uniform internal structure, strong corrosion resistance and wear resistance, and dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A low-pressure casting method for wear-resistant aluminum alloy bicycle accessories, comprising the steps of:

[0026] (a) Prepare aluminum alloy melt: place the aluminum alloy in a heating furnace, heat and melt the aluminum alloy at a high temperature, so that the aluminum alloy is melted into the molten metal;

[0027] (b) Preparation of the mold and casting shape before pouring: the squeeze casting machine adopts a detachable squeeze casting mold, removes the aluminum slag and the combustion residue of the sand core with air before use, and then coats the paint for maintenance and checks the airtightness Check whether the gate is blocked, and check whether the opening and closing mold has misalignment and sealing problems;

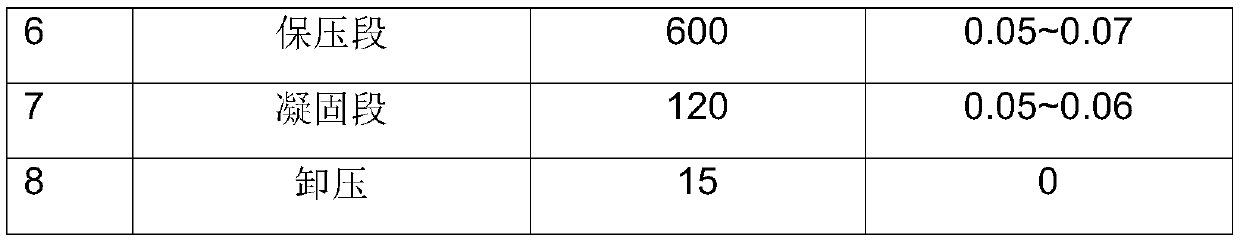

[0028] (c) Low-pressure pouring: call the designed pressure-time curve, carry out low-pressure pouring and solidify under pressure, including raising liquid, filling, pressurizing, maintaining pressure, solidifying, and depressurizing, forming a...

Embodiment 2

[0042] A low-pressure casting method for wear-resistant aluminum alloy bicycle accessories, comprising the steps of:

[0043] (a) Prepare aluminum alloy melt: place the aluminum alloy in a heating furnace, heat and melt the aluminum alloy at a high temperature, so that the aluminum alloy is melted into the molten metal;

[0044] (b) Preparation of the mold and casting shape before pouring: the squeeze casting machine adopts a detachable squeeze casting mold, removes the aluminum slag and the combustion residue of the sand core with air before use, and then coats the paint for maintenance and checks the airtightness Check whether the gate is blocked, and check whether the opening and closing mold has misalignment and sealing problems;

[0045] (c) Low-pressure pouring: call the designed pressure-time curve, carry out low-pressure pouring and solidify under pressure, including raising liquid, filling, pressurizing, maintaining pressure, solidifying, and depressurizing, forming a...

Embodiment 3

[0059] A low-pressure casting method for wear-resistant aluminum alloy bicycle accessories, comprising the steps of:

[0060] (a) Prepare aluminum alloy melt: place the aluminum alloy in a heating furnace, heat and melt the aluminum alloy at a high temperature, so that the aluminum alloy is melted into the molten metal;

[0061] (b) Preparation of the mold and casting shape before pouring: the squeeze casting machine adopts a detachable squeeze casting mold, removes the aluminum slag and the combustion residue of the sand core with air before use, and then coats the paint for maintenance and checks the airtightness Check whether the gate is blocked, and check whether the opening and closing mold has misalignment and sealing problems;

[0062] (c) Low-pressure pouring: call the designed pressure-time curve, carry out low-pressure pouring and solidify under pressure, including raising liquid, filling, pressurizing, maintaining pressure, solidifying, and depressurizing, forming a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com