Method for manufacturing dissimilar aluminum alloy composite materials by arc added materials

A dissimilar aluminum alloy and additive manufacturing technology, which is applied in manufacturing tools, arc welding equipment, metal processing equipment, etc., can solve problems such as difficulty in supplying large forgings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

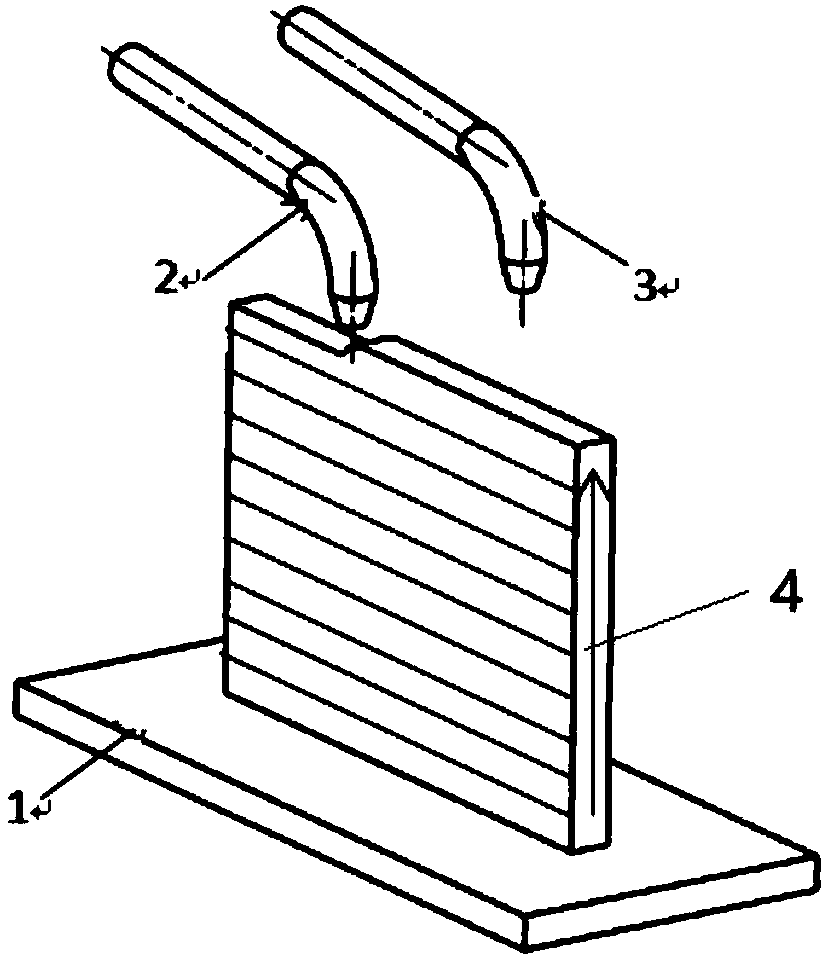

[0027] Embodiment 1: This embodiment relates to a method for manufacturing dissimilar aluminum alloy composite materials by arc additive manufacturing. Taking arc additive manufacturing of composite aluminum alloy plates as an example, the following steps are included;

[0028] (1) The substrate material is 6061 aluminum alloy, and the surface is cleaned with acetone solution. The wire material is 4043 and 5356 welding wire, the diameter of the welding wire is 1.2mm, the protective gas flow is 18L / min, and the purity of argon is 99.99%. 5356 layer wire feeding speed 5.6m / min, welding torch walking speed 3.5mm / s;

[0029] (2) Oil cloth protective cover during deposition to ensure inert gas atmosphere;

[0030] (3) Deposit 4043 welding wire on the 6061 aluminum alloy plate, then deposit 5356 welding wire on the 4043 deposition layer, and the height between layers is 3mm;

[0031] (4) After testing, it is found that the hardness value of the composite material is about 70HV, th...

Embodiment 2

[0032] Embodiment 2: This embodiment relates to a method for manufacturing dissimilar aluminum alloy composite materials by arc additive manufacturing, taking arc additive manufacturing of composite aluminum alloy plates as an example, including the following steps;

[0033] (1) The substrate material is 6061 aluminum alloy, and the surface is cleaned with acetone solution. The wire material is 4043 and 5356 welding wire, the diameter of the welding wire is 1.2mm, the protective gas flow is 18L / min, and the purity of helium is 99.99%. 5356 layer wire feeding speed 5.6m / min, welding torch walking speed 3.5mm / s;

[0034] (2) Oil cloth protective cover during deposition to ensure inert gas atmosphere;

[0035] (3) Deposit 4043 welding wire on the 6061 aluminum alloy plate, then deposit 5356 welding wire on the 4043 deposition layer, and the height between layers is 3mm;

[0036] (4) After testing, it is found that the hardness value of the composite material is about 70HV, the ...

Embodiment 3

[0037] Embodiment 3: This embodiment relates to a method for manufacturing dissimilar aluminum alloy composite materials by arc additive manufacturing, taking arc additive manufacturing of composite aluminum alloy plates as an example, including the following steps;

[0038] (1) The substrate material is 6061 aluminum alloy, and the surface is cleaned with acetone solution. The wire material is 4043 and 5356 welding wire, the diameter of the welding wire is 1.2mm, the protective gas flow is 18L / min, and the purity of argon is 99.99%. 5356 layer wire feeding speed 5.6m / min, welding torch walking speed 3.5mm / s;

[0039] (2) Oil cloth protective cover during deposition to ensure inert gas atmosphere;

[0040] (3) Deposit the 5356 welding wire on the 6061 aluminum alloy plate, and then deposit the 4043 welding wire on the 5356 deposition layer, and the height between layers is 3mm;

[0041] (4) After testing, it is found that the hardness value of the composite material is about...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com