Preparation method of transparent camouflage material

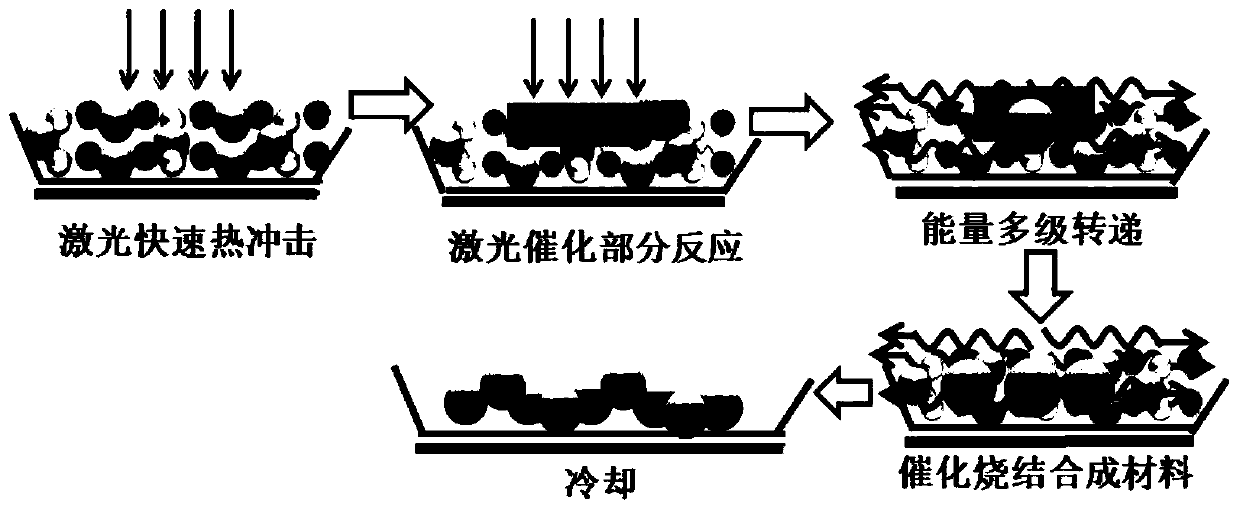

A stealth material and transparent technology, applied in the field of laser catalytic sintering transparent stealth materials, to achieve high transmittance, high transparency, and dense sintered samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

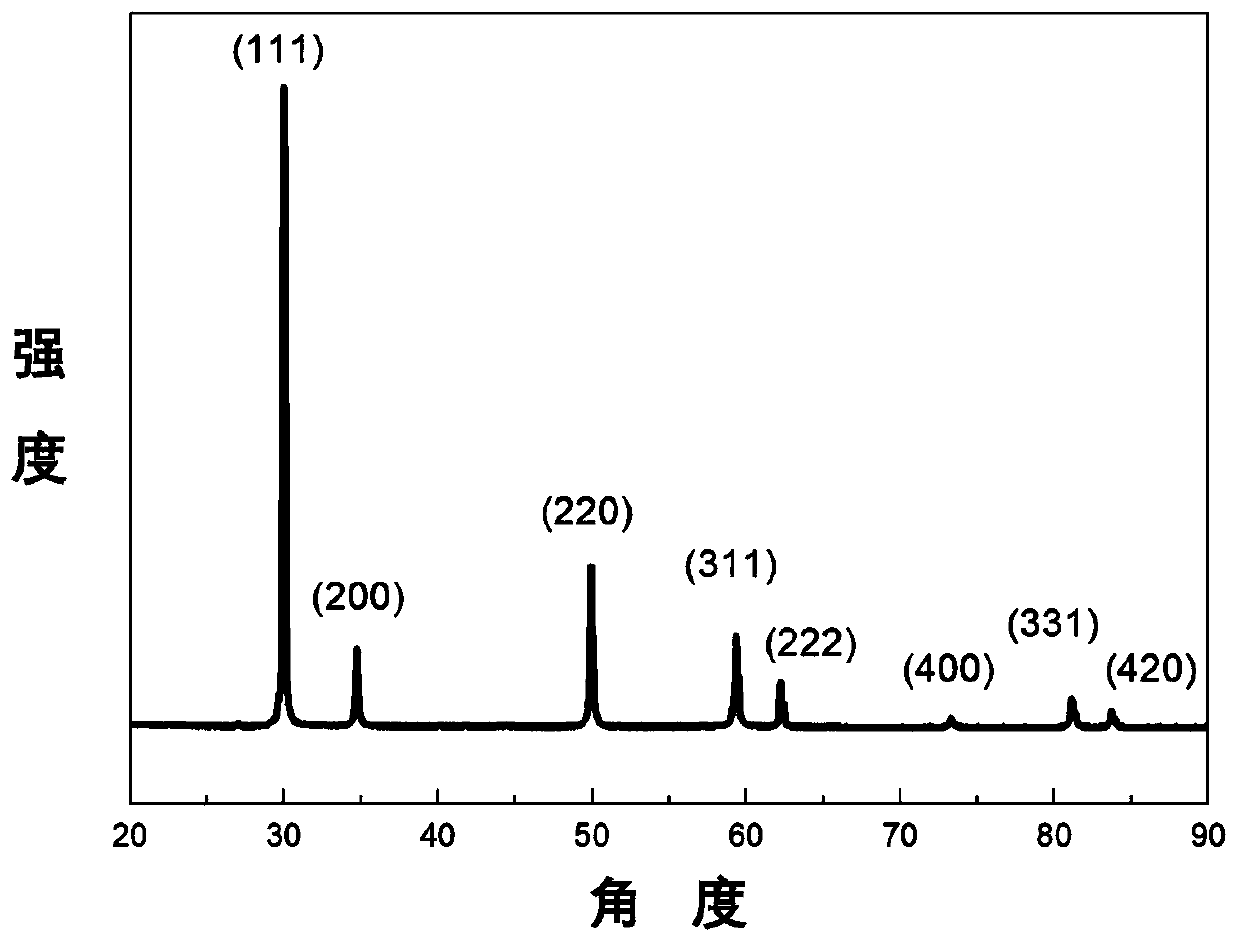

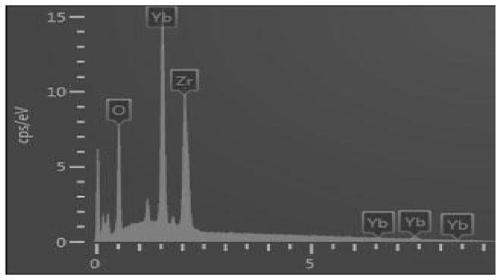

[0029] The raw material ZrO 2 Powder, LiF and Yb with a mass fraction of 5% 2 o 3 Powder mixing, wherein the molar ratio of Yb and Zr elements is 1:1, the raw materials are put into a zirconia ball mill tank for ball milling, with ethanol as the ball milling medium, the speed is 400rpm, the ball milling time is 24 hours, and the particle size after high energy ball milling is between 500nm-1μm During the milling process, the mixture after ball milling is granulated to obtain a product with smaller microscopic particle size and high density. The binder with a mass fraction of 8% is added to the uniformly mixed powder in two to three times, ground for 5 hours, sieved, and the mesh number of the sieve is 500 mesh, and the sieved compaction is performed at 500 ° C. 10 hours to remove air bubbles, and grind again after natural cooling. The ground powder is formed by a hydraulic press, and then compacted by isostatic pressing at 100MPa for 3 minutes. After the pressure is release...

Embodiment 2

[0031] The raw material ZrO 2 Powder, LiF and Yb with a mass fraction of 0.5% 2 o 3 Powder mixing, wherein the molar ratio of Yb and Zr elements is 1:1, the raw materials are put into a zirconia ball mill tank for ball milling, with ethanol as the ball milling medium, the speed is 400rpm, the ball milling time is 24 hours, and the particle size after high energy ball milling is between 500nm-1μm During the milling process, the mixture after ball milling is granulated to obtain a product with smaller microscopic particle size and high density. The binder with a mass fraction of 8% is added to the uniformly mixed powder in two to three times, ground for 5 hours, sieved, and the mesh number of the sieve is 500 mesh, and the sieved compaction is performed at 500 ° C. 12 hours to remove air bubbles, and grind again after natural cooling. The ground powder is formed by a hydraulic press, compacted under isostatic pressure at 150MPa, and kept for 5 minutes. After the pressure is r...

Embodiment 3

[0033] The raw material nano ZrO 2 Powder and Nano Yb 2 o 3 Powder mixing, wherein the molar ratio of Yb and Zr elements is 1:1, the raw materials are put into a zirconia ball mill tank for ball milling, with acetone as the ball milling medium, the speed is 400rpm, and the ball milling time is 12 hours. After high-energy ball milling, the particle size is between 50-200nm During the milling process, the mixture after ball milling is granulated to obtain a product with smaller microscopic particle size and high density. The binder with a mass fraction of 7% is added to the uniformly mixed powder in two to three times, ground for 3 hours, sieved, compacted after sieving, and debonded at 500°C for 12 hours to remove air bubbles. After natural cooling, grind again evenly. The ground powder is molded by a hydraulic press at 15MPa, held for 3s, and placed in a copper crucible after pressure relief. Select a semiconductor laser with a laser wavelength of 980nm and a laser power of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| power | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com