FRPO composite reinforced hollow winding pipe and preparation method thereof

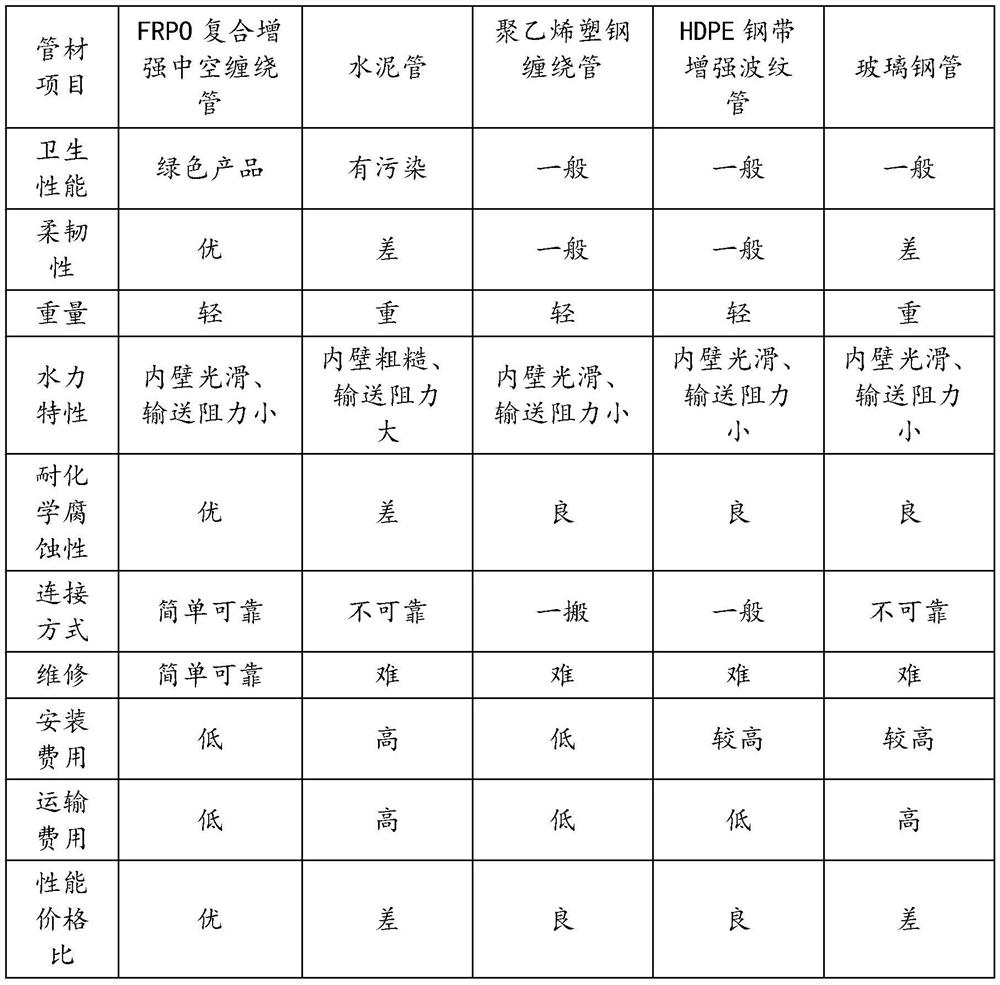

A composite reinforced and wound pipe technology, which is applied in the direction of pipes, rigid pipes, pipeline protection, etc., can solve the problems of pipelines such as poor flexibility and chemical corrosion resistance, no sanitation and environmental protection, and insufficient service life, so as to achieve long service life, The effect of light weight and improved internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

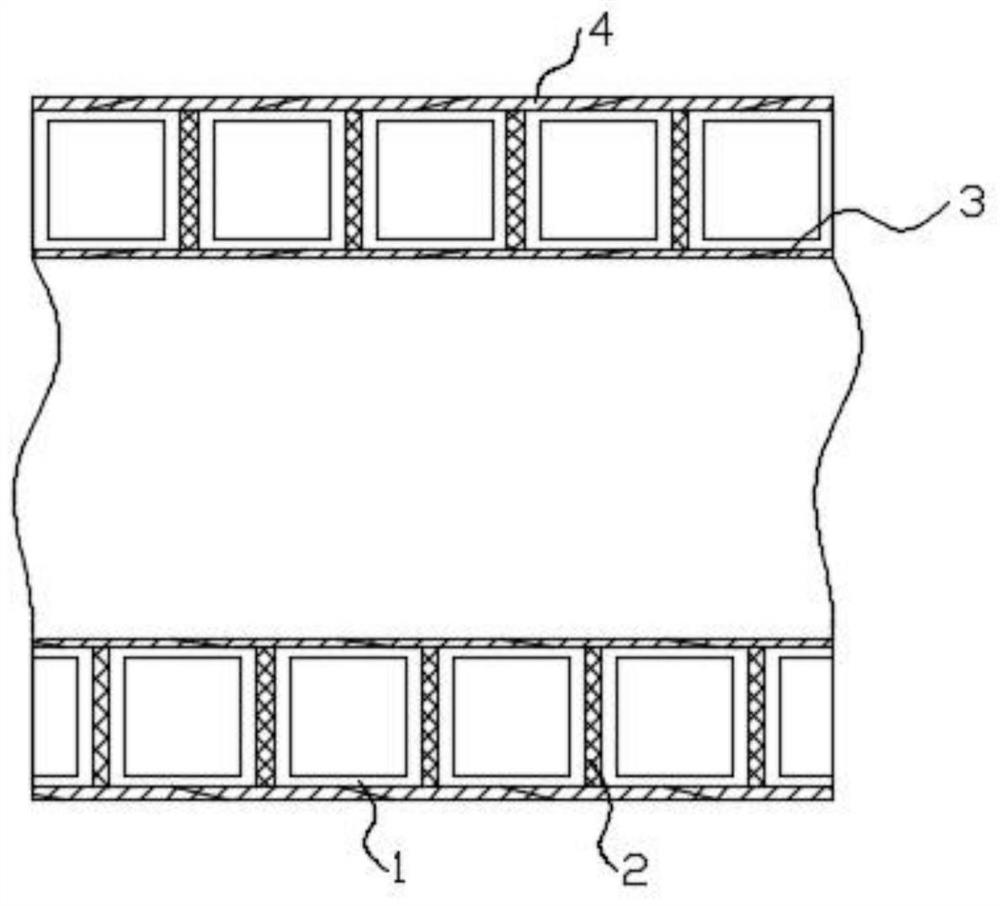

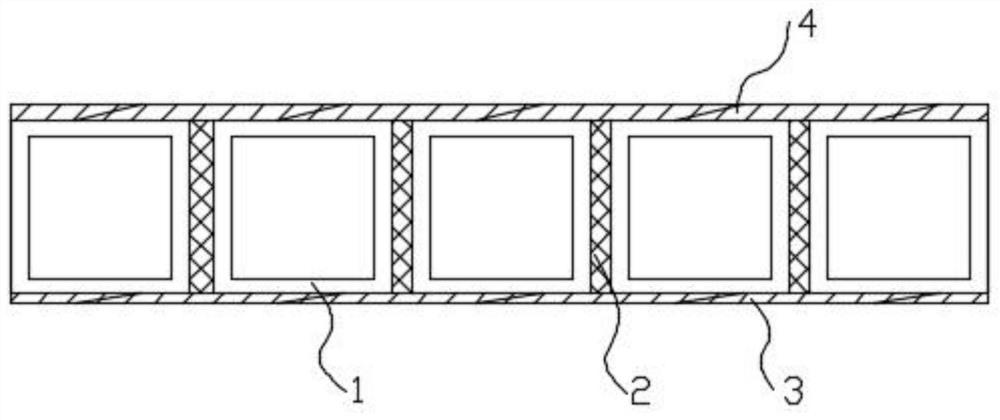

[0039] Such as figure 1 and figure 2 As shown, a FRPO composite reinforced hollow winding pipe includes a winding pipe body formed by winding a rectangular pipe 1. The inner wall and the outer wall of the winding pipe body are respectively provided with a wear-resistant layer 3 and a compression and stretching layer 4. The grinding layer 3 is a modified polyolefin wear-resistant material, the compressive and tensile-resistant layer 4 is a polypropylene material, and the material of the rectangular tube 1 includes polypropylene material, nanometer material, glass fiber material and compatibilizer.

[0040] In another embodiment, the smoothness of the inner wall and the outer wall of the winding pipe body is Ra0.012-Ra0.009.

[0041] In another embodiment, such as figure 2 As shown, the inside of the winding pipe body is respectively provided with adhesive reinforcing ribs 2 between two adjacent rectangular pipes 1 .

[0042] In another embodiment, the raw material of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com