Connecting rod automation electro-brush plating machine tool

A technology of brush plating and connecting rod, which is applied in the field of brush plating, can solve the problems of inability to guarantee qualified products, difficulty in cleaning, and low efficiency of brush plating, so as to improve the work efficiency of brush plating, improve the quality of coating, and the efficiency of brush plating Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1 machine tool structure of the present invention

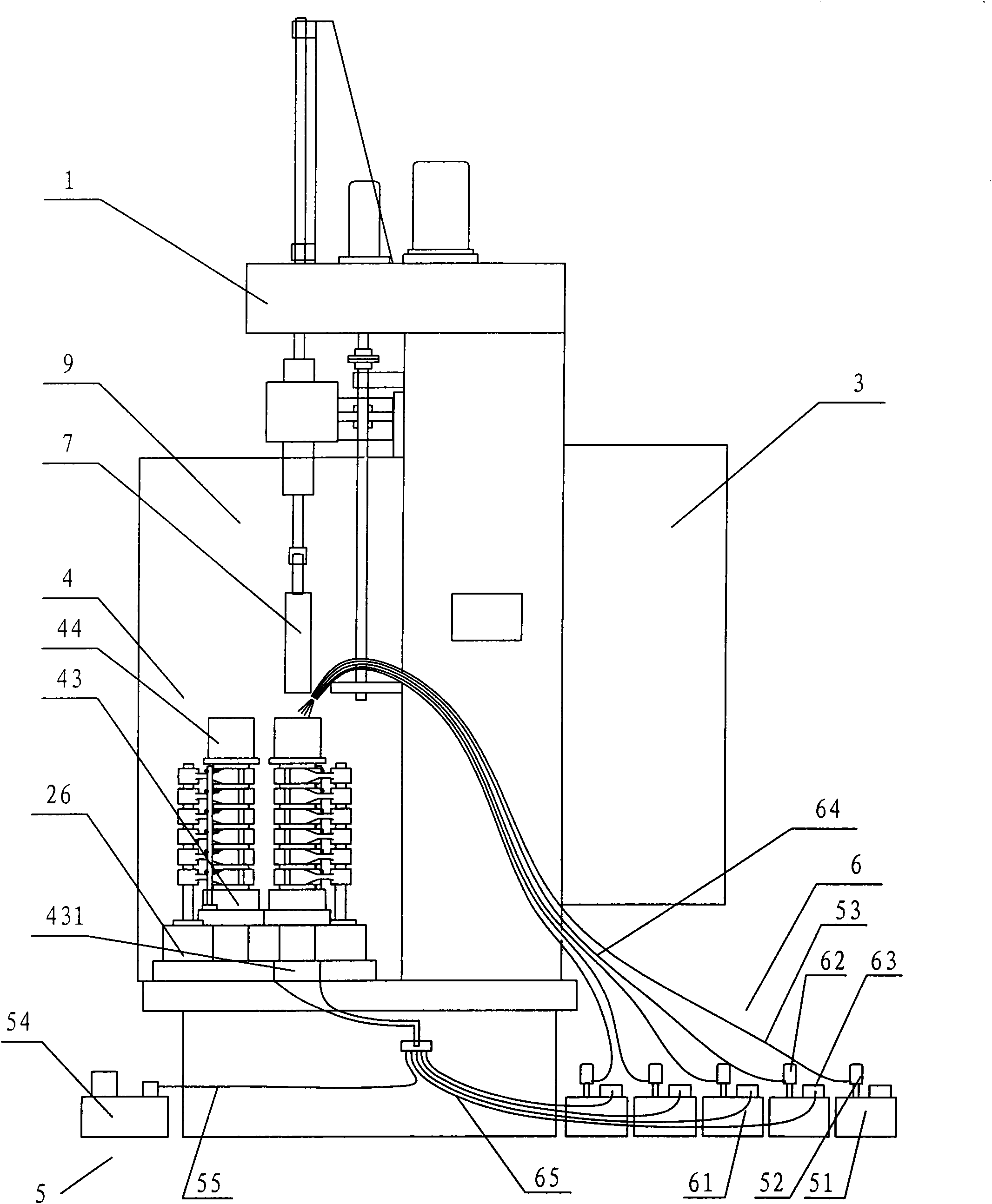

[0045] Such as Figure 1 to Figure 5 As shown, a connecting rod automatic brush plating machine tool includes a main rotation transmission device 1, a plating pen advance and retreat device 2, an electric control device 3, two sets of clamp devices 4, a flushing system 5 and a liquid supply recovery system 6;

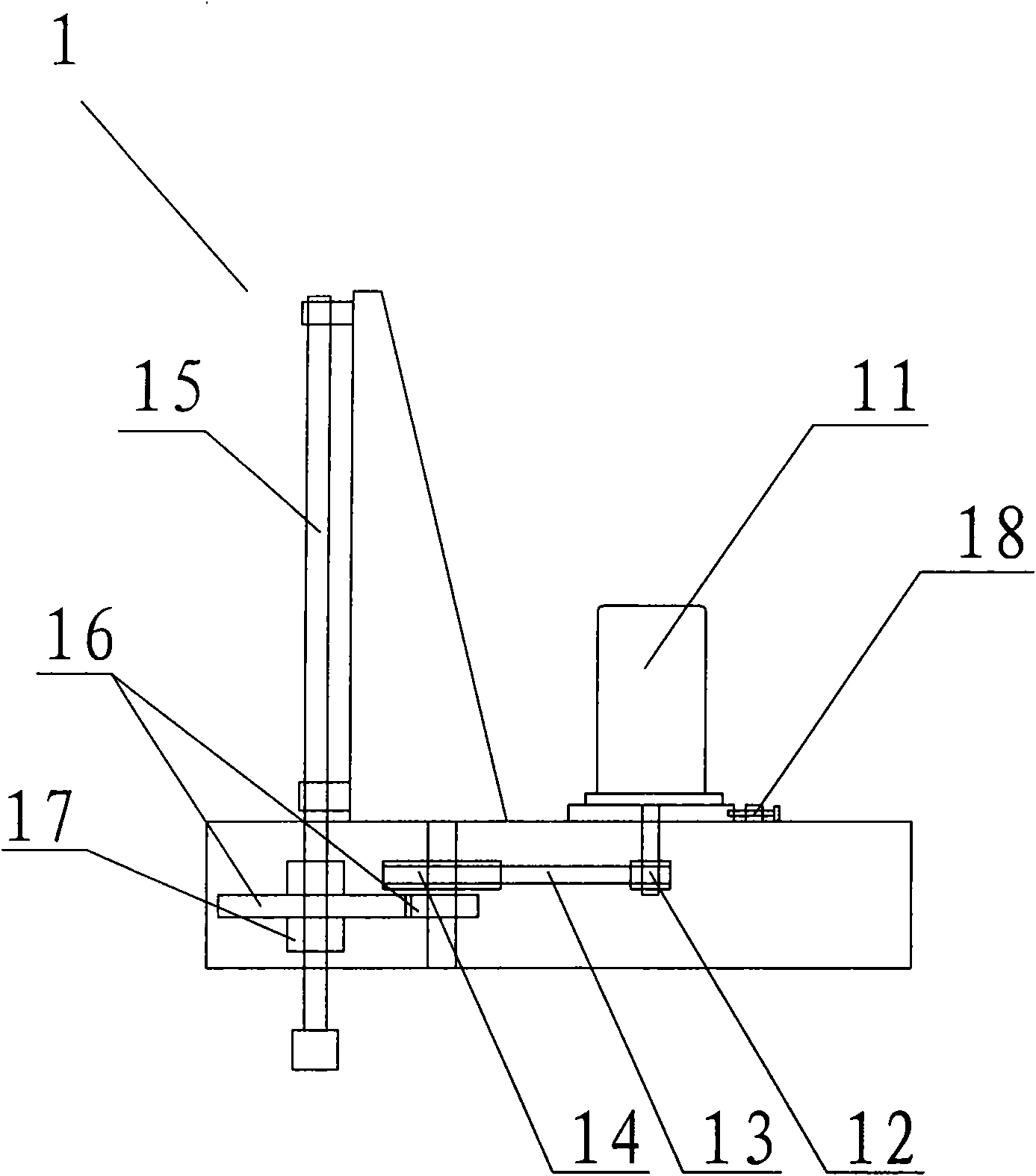

[0046] The main rotation transmission device 1 is provided with a main rotation motor 11 on a motor base, the main rotation motor 11 is connected with the driving pulley 12, and the driving pulley 12 is connected with the driven pulley 14 through the timing belt 13; a rolling spline pair 15 is connected to the driven pulley 14 through the gear 16; the outer sleeve of the rolling spline pair 15 is provided with a shaft sleeve 17;

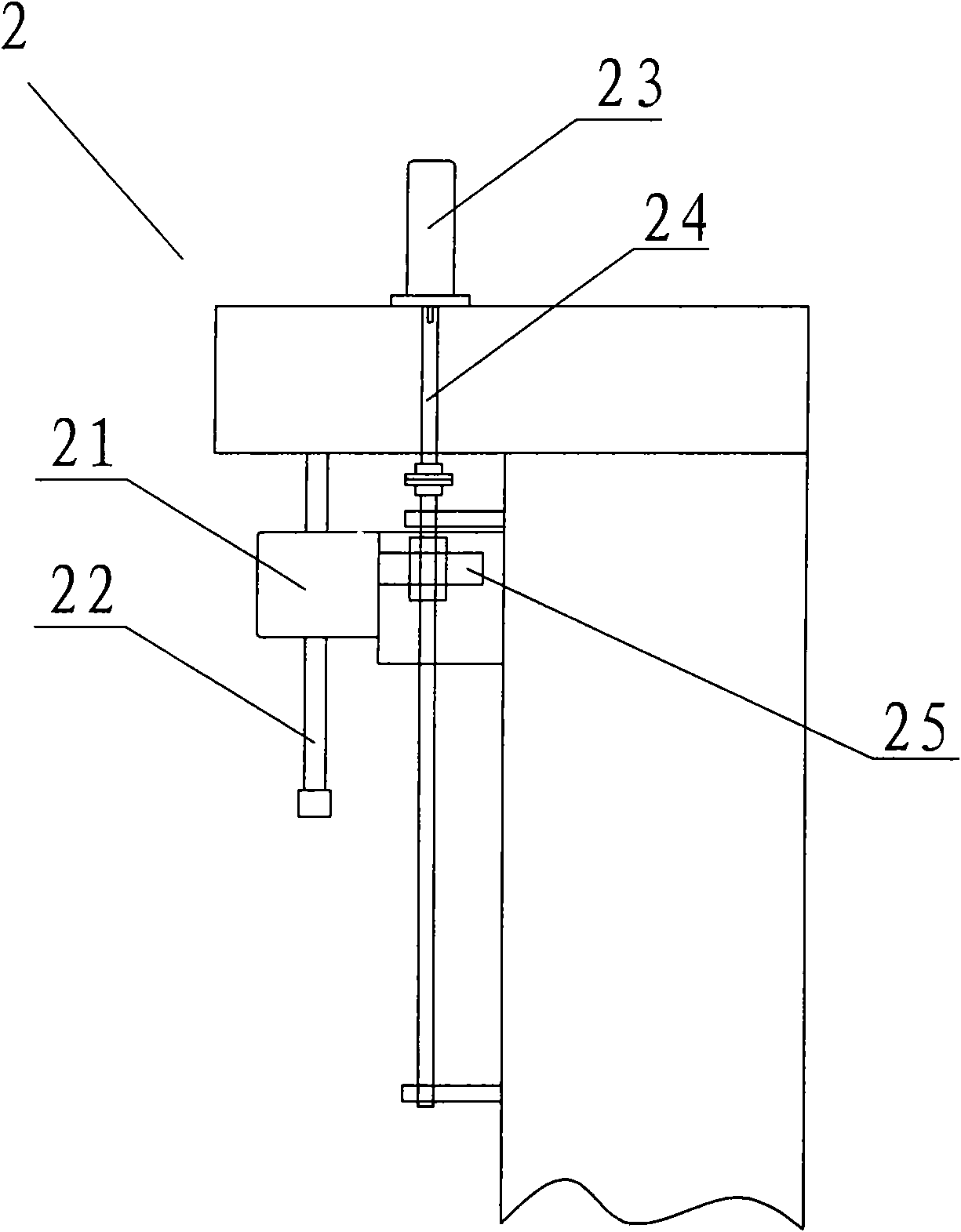

[0047] The spindle box 21 of the plating pen advance and retreat device 2 is connected with the rolling spline pair 15 on the main rotation transmission device 1 through th...

Embodiment 2

[0057] Embodiment 2 The specific brush plating method of the machine tool of the present invention

[0058] a. Parts installation: the fixture device is set on the base, which is an insulating board. The fixture device is equipped with a small connecting rod hole fixed mandrel, a connecting rod large hole rough positioning device and a support seat; when clamping, the small holes of the six connecting rods are placed on the connecting rod small hole fixed mandrel in turn, and the connecting rod The end of the large hole leans against the rough positioning device for the large hole of the connecting rod.

[0059] b. Alignment of parts: make a mandrel for the large hole of the connecting rod, whether the mandrel matches the shape and size of the connecting rod, and the upper end of the mandrel is connected to the main shaft. After the connecting rod is roughly positioned, start the machine tool, and first return the machine tool to zero (returning to zero means that the spindle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com