Corrosion-resistant and wear-resistant tool steel

A wear-resistant, tool steel technology, applied in the field of tool steel materials, can solve the problems of high cost of alloys, etc., and achieve the effects of high cost performance, excellent corrosion resistance and wear resistance, excellent corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

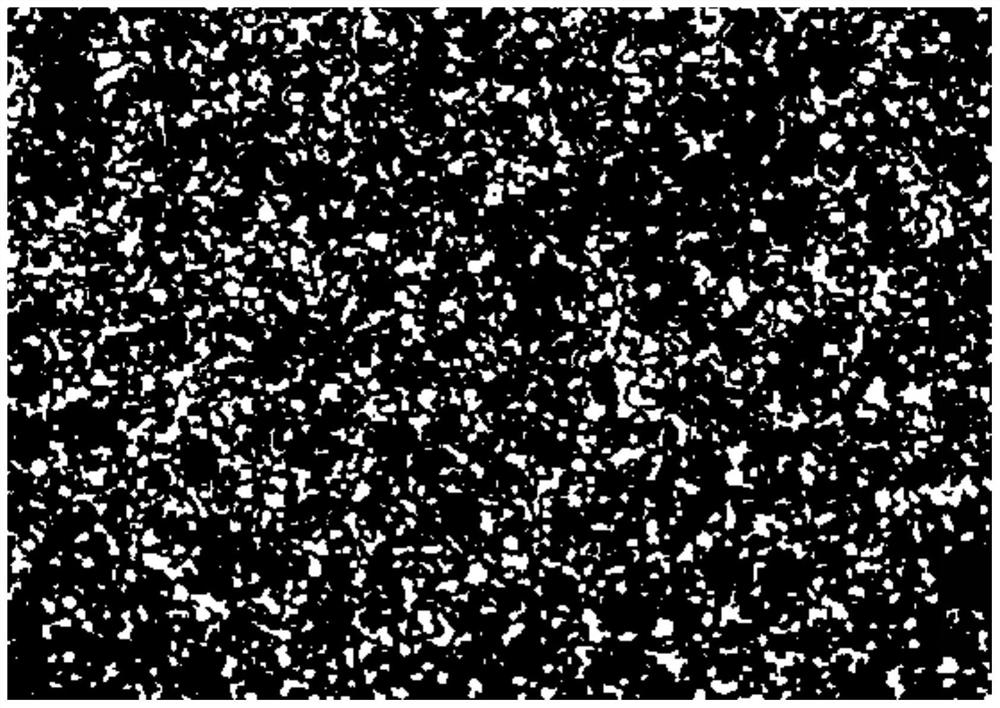

[0077] The alloy of embodiment 1, microstructure such as figure 1 As shown, the second phase composition is Cr-rich M7C3 carbide and V-rich MC carbide, at least 80% of the two carbides have a particle size ≤ 3 μm, and the volume fraction of Cr-rich M7C3 carbide is 12%-20%, The volume fraction of V-rich MX carbides is 6%-10%.

Embodiment 2

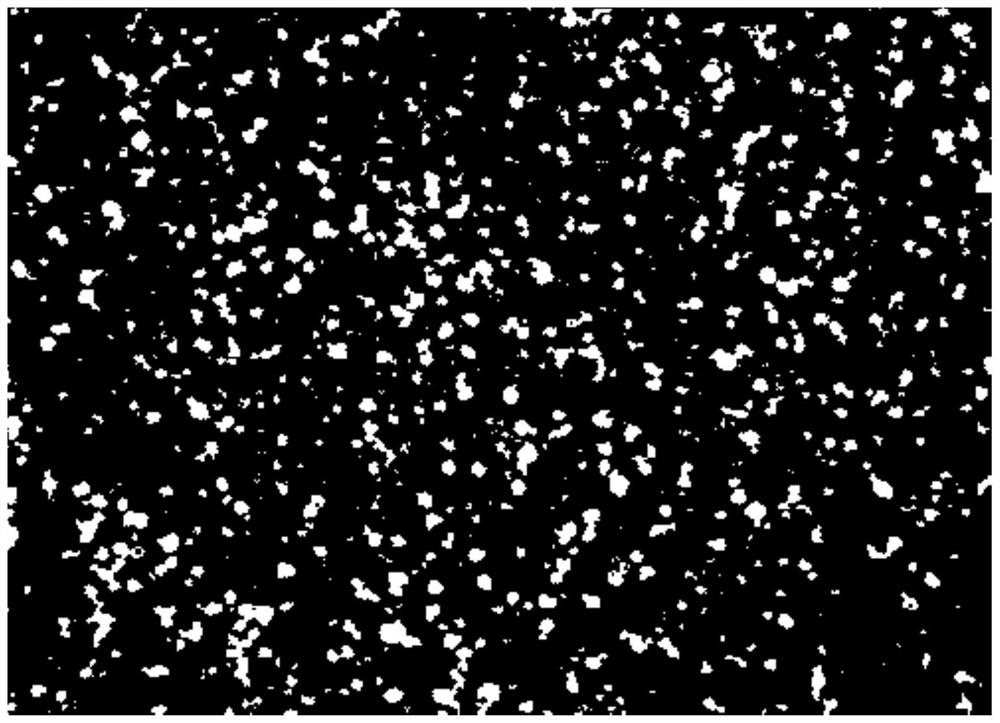

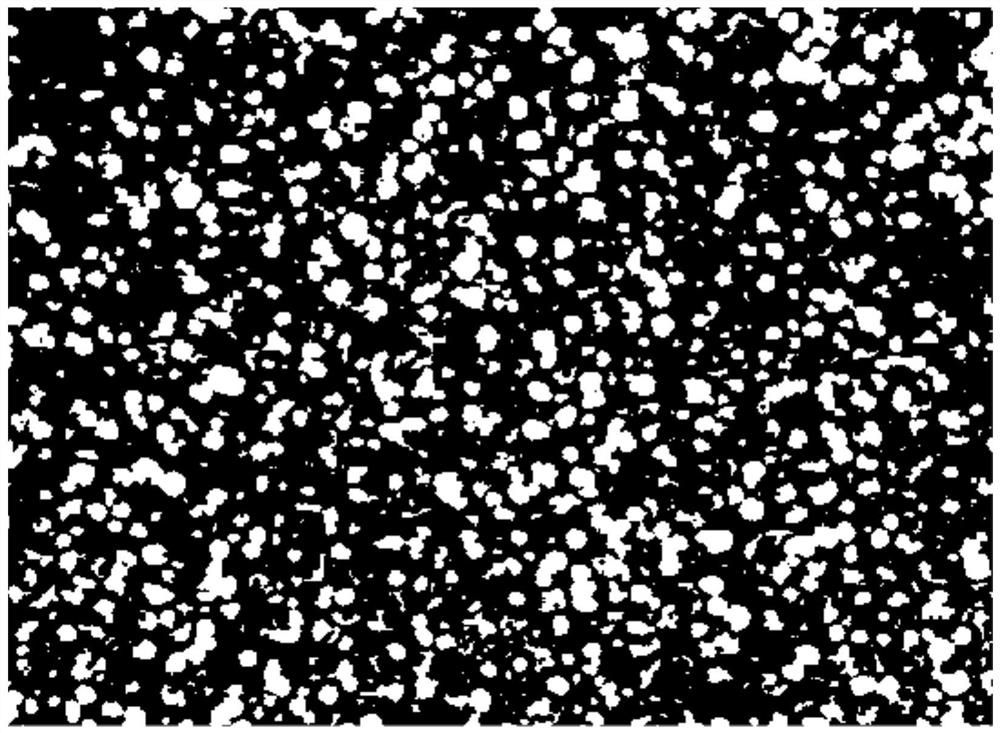

[0078] Among the alloys of embodiment 2 to embodiment 8, the microstructures of embodiment 2 and embodiment 4 are respectively as follows figure 2 with image 3 As shown, in addition to the above two kinds of carbides, it also contains Ti-rich MX carbides with a particle size of ≤7 μm, at least 80% of which have a particle size of ≤3 μm, and are approximately spherical particles. The high-hardness Ti-rich MX carbides are distributed in the matrix in a fine dispersion manner, which can improve the wear resistance without too much damage to the machinability.

Embodiment 9

[0079] In the alloy of Example 9, due to the small amount of Ti added, it is detected that the wear-resistant TiC particle phase formed is too small, and the improvement of the wear resistance is limited.

[0080] (2) Heat treatment hardness

[0081] The alloys of Examples 1 to 9 were heat treated according to the process parameters in Table 3, and the hardness was tested.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com