Plating pen for electro-brush plating inner bore parts

A brush plating technology for parts and components, applied in the direction of electrodes, etc., can solve problems such as temperature rise, poor circulation of plating solution, and short service life of sheaths, so as to prolong service life, reduce brush plating cost, and have good corrosion resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

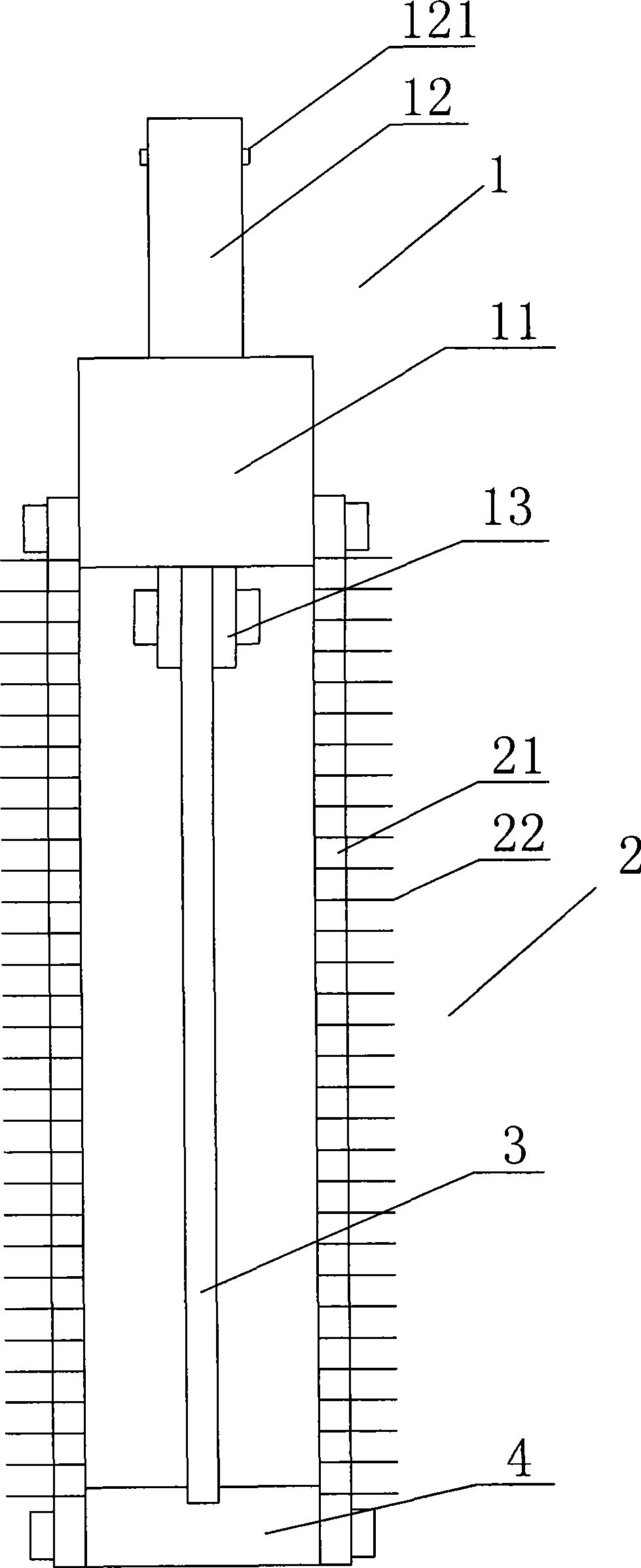

[0037] Such as figure 1 As shown, a plating pen for electric brush plating of inner hole parts includes a pen handle 1 and a pen body 2. The pen handle 1 is provided with a suspension part 12 on the top of a handle main body 11, and Hanging pin 121 is also provided, and a clamping portion 13 is provided at the bottom of hanging portion 12; the pen body 2 is made up of two plates 21 and bristles 22, and the bristles 22 are planted on one side of each plate body 21, and the plate The body 21 is connected to the handle main body 11; the clamping part 13 clamps an anode 3; the plate body 21 is arranged on both sides of the anode 3 in parallel; the bottom ends of the two plate bodies 21 and the anode 3 are both arranged on an insulating beam 4 and do not touch each other.

[0038] The above-mentioned board body 21 is made of insulating material, and the insulating material is selected from PVC material, and each part of the above-mentioned pen handle 1 has an integrated structure...

Embodiment 2

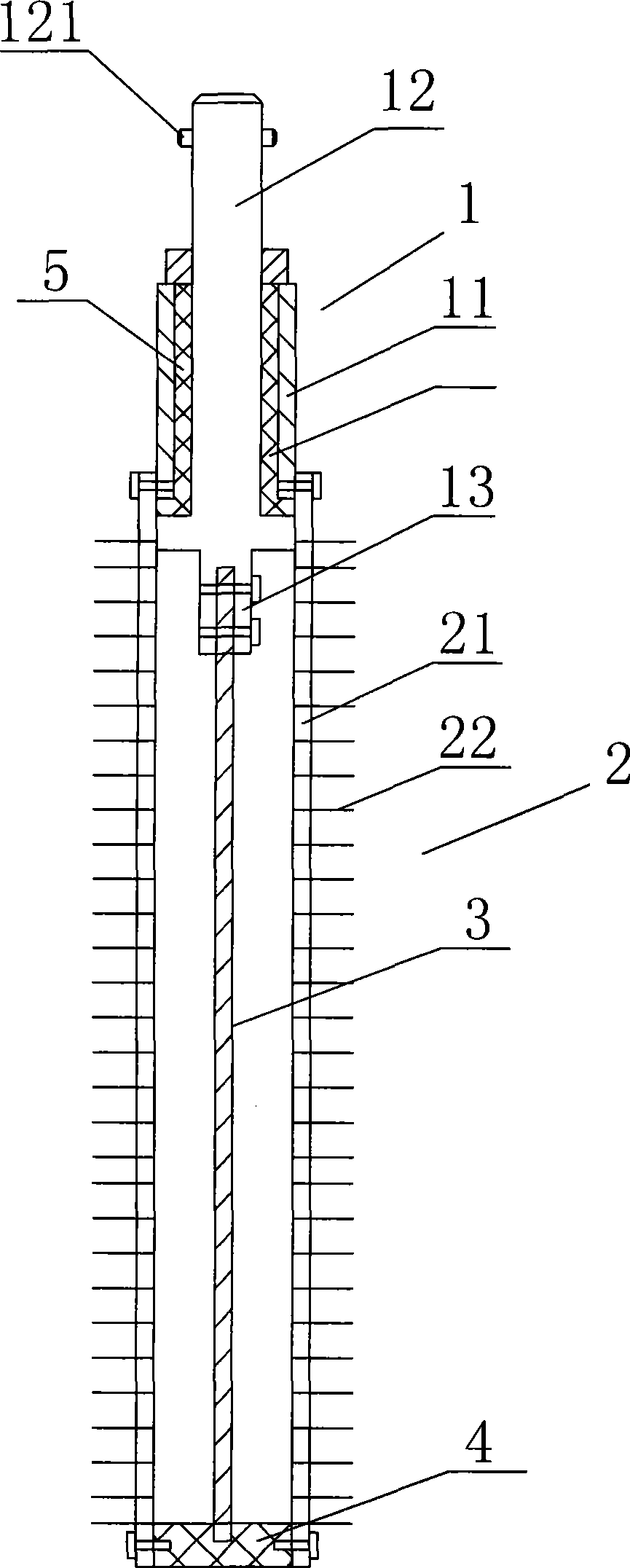

[0040] Such as figure 2 As shown, a plating pen for electric brush plating of inner hole parts includes a pen handle 1 and a pen body 2, and the pen handle 1 is a handle main body 11 which is a sleeve structure, and the sleeve structure is equipped with There is a hanging part 12, and the hanging part 12 is also provided with a hanger pin 121. A clamping part 13 is provided at the bottom of the hanging part 12. The integral structure of the hanging part 12 and the clamping part 13 runs through the pen handle main body 11, and between the two An insulating sleeve 4 is provided, and a locking nut 5 is provided for locking the handle main body 11 and the insulating sleeve 5 .

[0041] The pen body 2 is composed of two plates 21 and bristles 22. The bristles 22 are planted on one side of the plates 21. The plates 21 are connected to the handle main body 11; the clamping part 13 clamps a The anode 3 is fastened by bolts and nuts between the clamping part 13 and the anode 3; the t...

Embodiment 3

[0045] Embodiment 3 Embodiment 1 of the present invention prepares the plating pen and is used for practical application embodiment

[0046] The plating solution used is a special brush plating solution for inner holes, and the current density is 10A dm -2 . The size after plating is Φ88-0.10.

[0047] 1. Brush plating steps:

[0048] 1. Preliminary preparation

[0049] (1) Initial processing

[0050] Connecting rods disassembled from old engines are cleaned and honed to remove fatigue layers.

[0051] (2) Preparation of plating pen

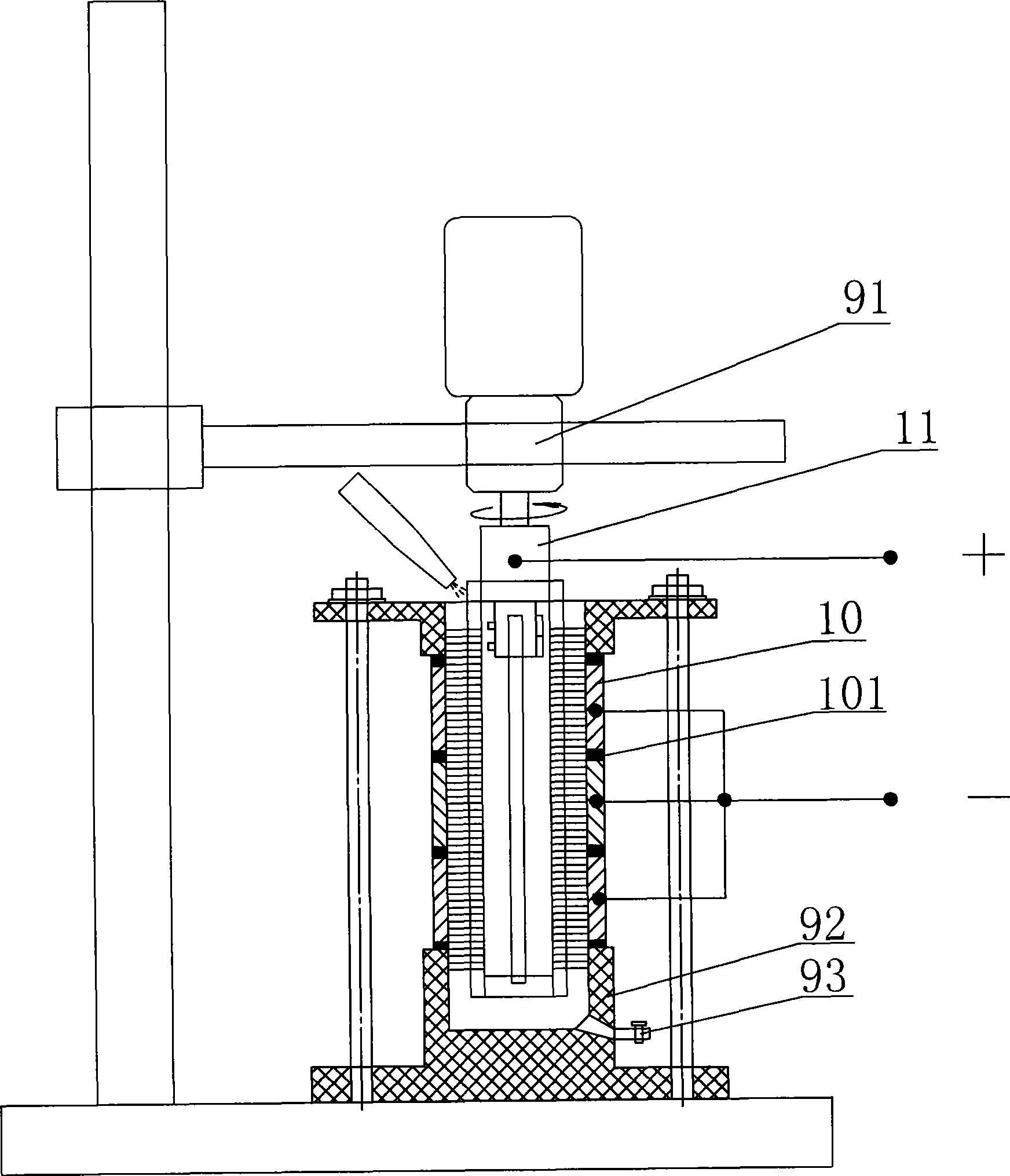

[0052] The prepared inner hole brush plating pen (described in embodiment 1) is installed on a liftable turntable 9 by a hanger pin, and (can be replaced by a vertical drilling machine) hanger pin 121 on the suspension part 12 is connected with the rotary motor 91.

[0053] (3) Installation of connecting rod

[0054] Use a special clamping and sealing device to install 6 connecting rods 10 with brush plating together, and the connecting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com