A kind of electric heating film for anti-icing and anti-fog of aircraft windshield glass and preparation method thereof

A windshield and electric heating film technology, applied in the field of electric heating film manufacturing, can solve the problems of complex structure, low efficiency, and no obvious improvement in auxiliary functions such as windshield energy-saving performance, etc., and achieve simple production process, corrosion resistance and wear resistance Excellent performance, easy to adjust the film color and light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

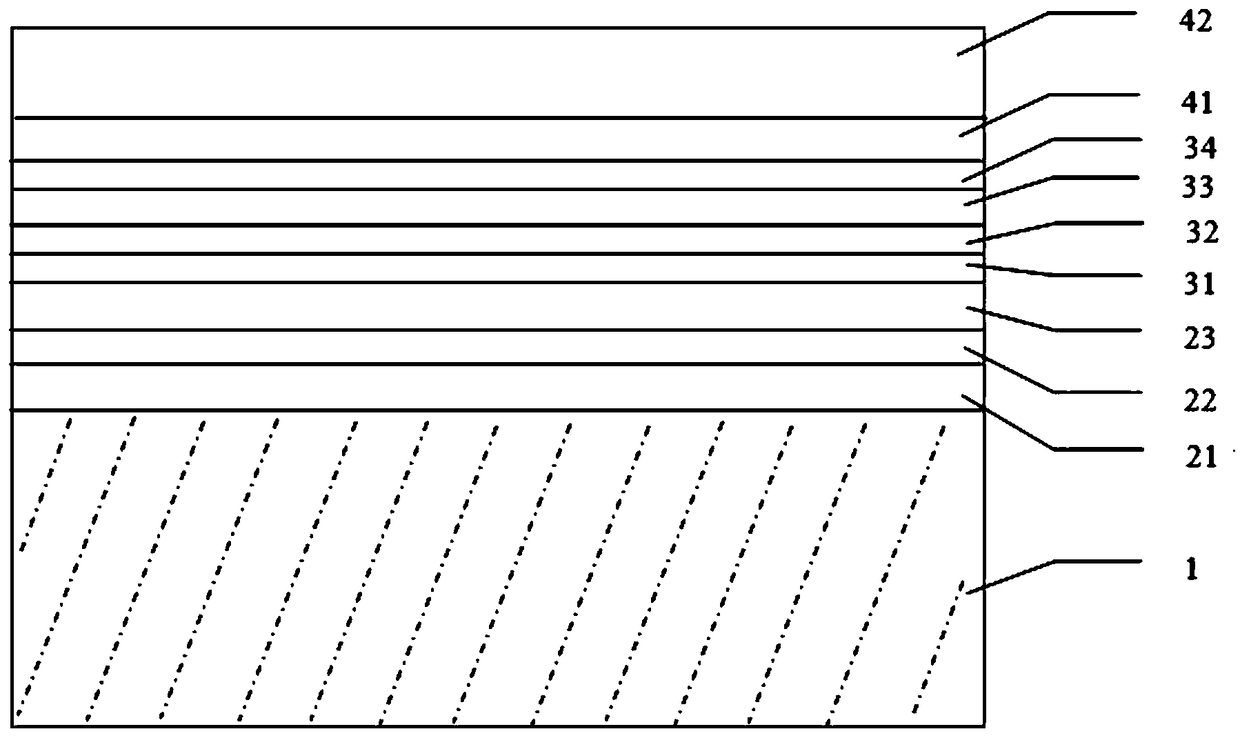

[0033] Such as figure 1 As shown, a kind of electric heating film for anti-icing and anti-fog of aircraft windshield of the present invention, described electric heating film for anti-icing and anti-fog of aircraft windshield comprises glass substrate, internal structure layer, electric heating function layer and the outer structural layer, the electric heating film used for anti-icing and anti-fogging of aircraft windshields includes a glass substrate, an inner structural layer, an electric heating functional layer and an outer structural layer from the inside to the outside.

[0034] The inner structure layer is used to prevent impurities in the windshield plexiglass base from entering the functional layer to affect the electric heating effect, and at the same time increase the adhesion of the film layer and have a certain conductivity, which is beneficial to improve the anti-icing and anti-fog performance. The outer structural layer provides protection for the film layer, i...

Embodiment 2

[0050] The difference between embodiment 2 and embodiment 1 is: a kind of electric heating film that is used for anti-icing and anti-fog of aircraft windshield of the present invention, the film layer thickness of described first silicon oxide layer 21 is 40nm, and described niobium oxide layer 22 has a film thickness of 20 nm, and the first zinc gallium oxide layer 23 has a film thickness of 12 nm.

[0051] The film thickness of the metal gold layer 31 is 10nm, the film thickness of the second zinc-gallium oxide layer 32 is 25nm, the film thickness of the zinc-aluminum oxide layer 33 is 25nm, and the metal The film thickness of the titanium layer 34 is 8 nm.

[0052] The film thickness of the indium tin oxide layer 41 is 30 nm, and the film thickness of the second silicon oxide layer 42 is 120 nm.

[0053] The preparation method of the electric heating film for anti-icing and anti-fog of aircraft windshield of the present invention comprises the following steps:

[0054] In...

Embodiment 3

[0059] The difference between embodiment 3 and embodiment 1 is: a kind of electric heating film that is used for anti-icing and anti-fog of aircraft windshield of the present invention, the film layer thickness of described first silicon oxide layer 21 is 50nm, and described niobium oxide layer 22 has a film thickness of 15 nm, and the first zinc gallium oxide layer 23 has a film thickness of 18 nm.

[0060] The film thickness of the metal gold layer 31 is 8nm, the film thickness of the second zinc-gallium oxide layer 32 is 18nm, the film thickness of the zinc-aluminum oxide layer 33 is 35nm, and the metal The film thickness of the titanium layer 34 is 12 nm.

[0061] The film thickness of the indium tin oxide layer 41 is 32 nm, and the film thickness of the second silicon oxide layer 42 is 155 nm.

[0062] The preparation method of the electric heating film for anti-icing and anti-fog of aircraft windshield of the present invention comprises the following steps:

[0063] In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com