A kind of ultra-thin low-voltage electrothermal film material in low temperature environment and preparation method thereof

A low-temperature environment, electrothermal film technology, applied in electrothermal devices, ohmic resistance heating, electrical components, etc., can solve the problems of complex equipment, less research, affecting electrical conductivity, etc., to improve the ability to withstand extreme environments, and the preparation process is simple. The effect of good electric heating performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

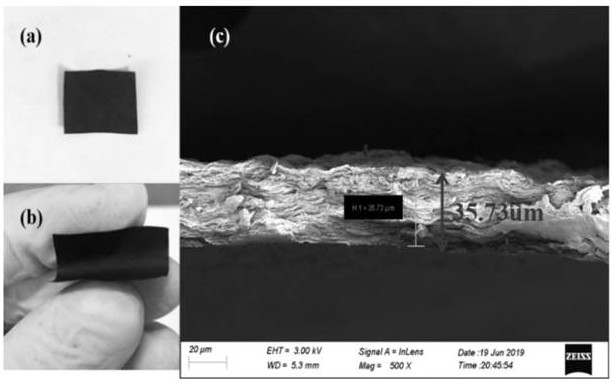

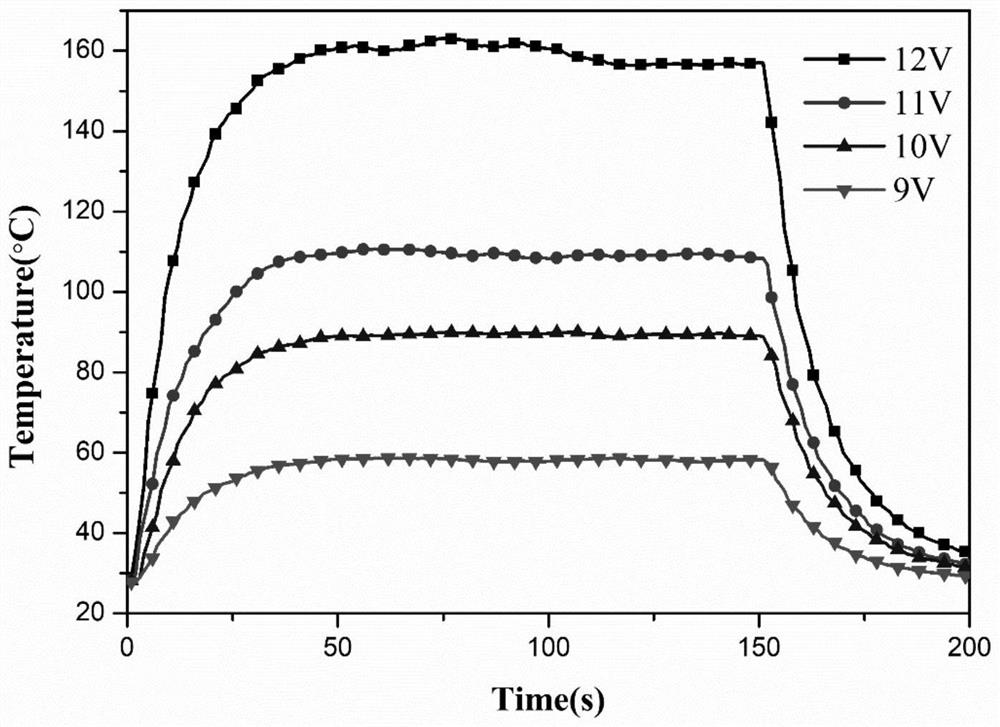

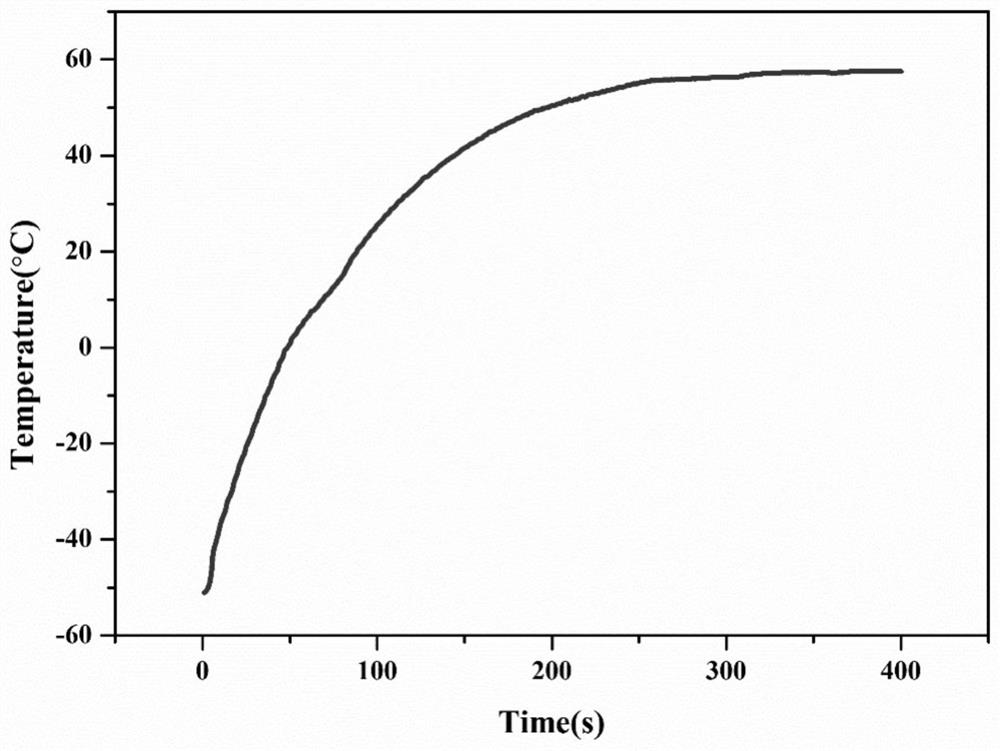

[0027] The implementation of the new ultra-thin voltage low-temperature resistant electric heating film is an electric heating film prepared by vacuum suction and filtration using polymer substrates, solvent water, titanium compounds, and linear conductive fillers as raw materials. Among them, the polymer matrix is selected from cellulose, the titanium series compound is selected from titanium carbide, and the linear conductive filler is selected from carbon nanotubes, which are prepared according to the following steps:

[0028] Step 1: At 60°C, add 40 parts by mass of cellulose to a three-necked flask equipped with a stirrer, a reflux condenser and solvent water, and stir for 4 hours after the addition is completed to completely dissolve to obtain a cellulose solution;

[0029] Step 2: Take the cellulose solution obtained in step 1, add 40 parts by mass of titanium carbide and 20 parts by mass of carbon nanotubes to it, and then ultrasonically stir the mixed conductive fill...

Embodiment 2

[0035] The new ultra-thin voltage and low-temperature resistant electric heating film is an electric heating film prepared by vacuum suction and filtration using a polymer matrix, solvent water, titanium compounds, and linear conductive fillers as raw materials. Among them, polyvinyl alcohol is selected as the polymer matrix, titanium nitride is selected as the titanium compound, and carbon fiber is selected as the linear conductive filler, which is prepared according to the following steps:

[0036] Step 1: At 70°C, add 50 parts by mass of polyvinyl alcohol to a three-necked flask equipped with a stirrer, a reflux condenser and solvent water, and stir for 5 hours after the addition is completed to completely dissolve it to obtain a cellulose solution;

[0037] Step 2: Take the polyvinyl alcohol solution obtained in step 1, add 35 parts by mass of titanium nitride and 15 parts by mass of carbon fiber, and then ultrasonically stir the mixed conductive filler for 2 hours to make ...

Embodiment 3

[0043] The implementation of the new ultra-thin voltage low-temperature resistant electrothermal film is an electrothermal film prepared by vacuum suction and filtration using a polymer matrix, solvent water, titanium compounds, and linear conductive fillers as raw materials. Among them, polyethylene glycol is selected as the polymer matrix, titanium carbonitride is selected as the titanium compound, and silver nanowires are selected as the linear conductive filler, which is prepared according to the following steps:

[0044] Step 1: At 80°C, add 60 parts by mass of cellulose to a three-necked flask equipped with a stirrer, a reflux condenser and solvent water, and stir for 6 hours after the addition is completed to completely dissolve it to obtain a cellulose solution;

[0045] Step 2: Take the polyethylene glycol solution obtained in step 1, add 30 parts by mass of titanium carbonitride and 10 parts by mass of silver nanowires, and then ultrasonically stir the mixed conductiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com