An air filter material capable of in-situ electrothermal sterilization and its preparation method

An air filter material, electric heating technology, applied in separation methods, filtration separation, membrane filters, etc., can solve the problem of not being able to disinfect and kill.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

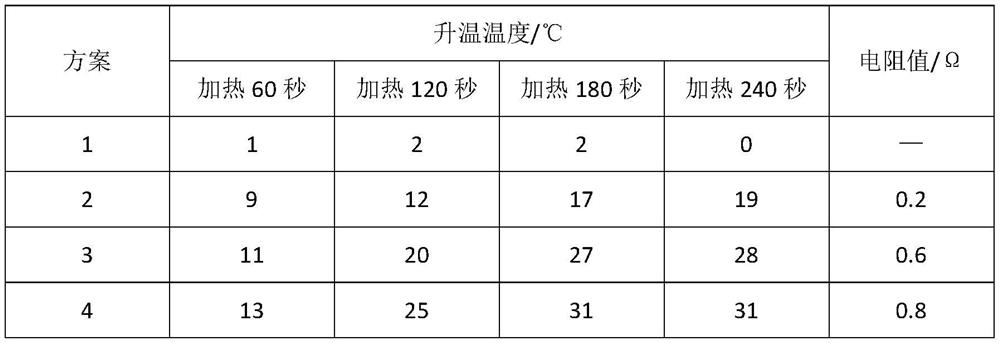

[0054] plan 1

[0055] This solution provides an air filter material that can be sterilized by electric heat in situ. The air filter material that can be sterilized by electric heat in situ includes, by weight, the following components: 100% glass microfiber cotton, and its beating and knocking Degree ≥ 19 degrees.

[0056] Scenario 2

[0057] This solution provides an air filter material that can be sterilized by electric heat in situ. The air filter material that can be sterilized by electric heat in situ includes, by weight, the following components: 100% carbon fiber, and the fiber diameter range of carbon fiber is 0.2 -1.2μm, the fiber length range is 1-15mm.

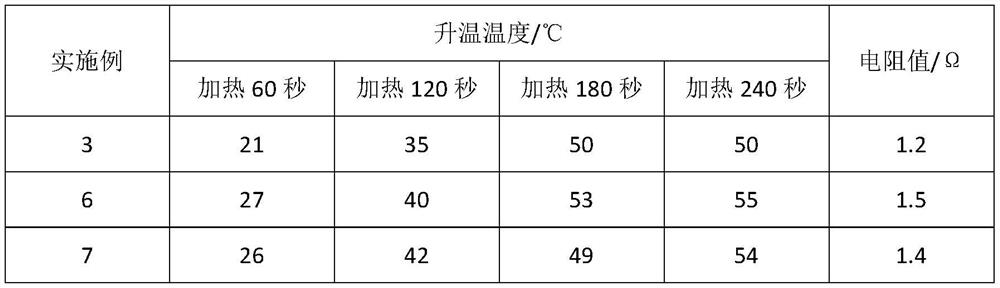

[0058] Option 3

[0059] This solution provides an air filter material that can be sterilized by electric heat in situ, and the air filter material that can be sterilized by electric heat in situ includes, by weight, the following components: 50% carbon fiber, 50% glass microfiber cotton , wherein the fiber dia...

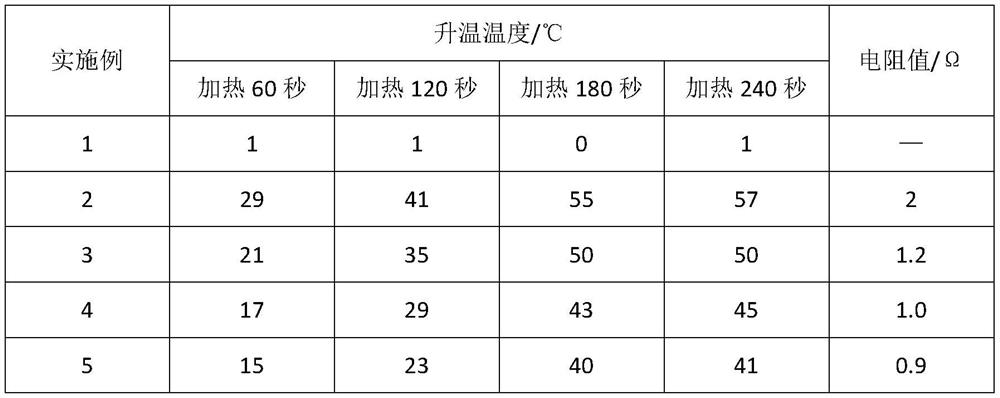

Embodiment 1

[0067] This embodiment provides an air filter material that can be sterilized by electric heat in situ. The air filter material that can be sterilized by electric heat in situ includes, by weight, the following components: 100% glass microfiber cotton, and it is beaten Percussion degree ≥ 19 degrees.

Embodiment 2

[0069] This embodiment provides an air filter material that can be sterilized by electric heat in situ. The air filter material that can be sterilized by electric heat in situ includes, by weight, the following components: 5% carbon fiber, 93% glass microfiber Cotton, 2% melamine formaldehyde resin, wherein the fiber diameter range of carbon fiber is 0.4-1μm, the fiber length range is 3-10mm, and the beating degree of glass microfiber cotton is ≥19 degrees.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com