Preparation method of stretchable electric heating fabric

An electric heating and fabric technology, applied in the field of materials, can solve the problems of difficulty in preparing the coating slurry for electric heating fabrics, poor stretchability, low bonding strength between conductive additives and fabrics, etc., and achieves improved electric heating performance and stable performance. , the effect of easy large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

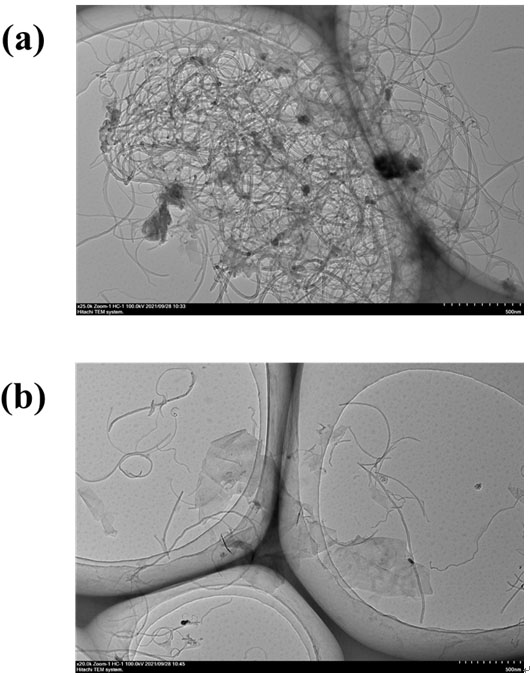

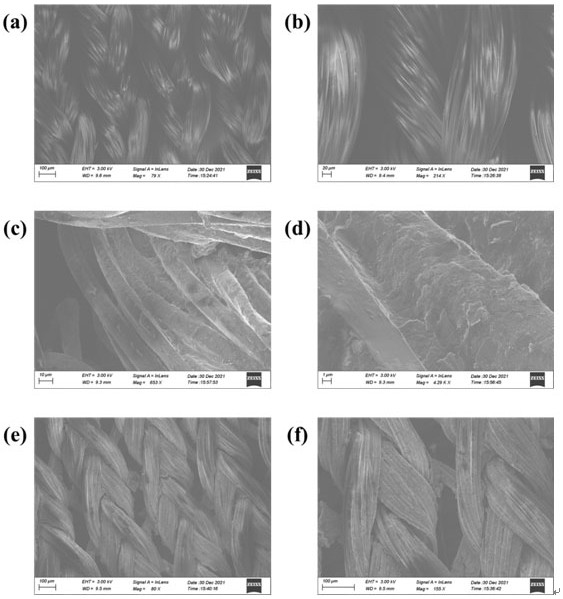

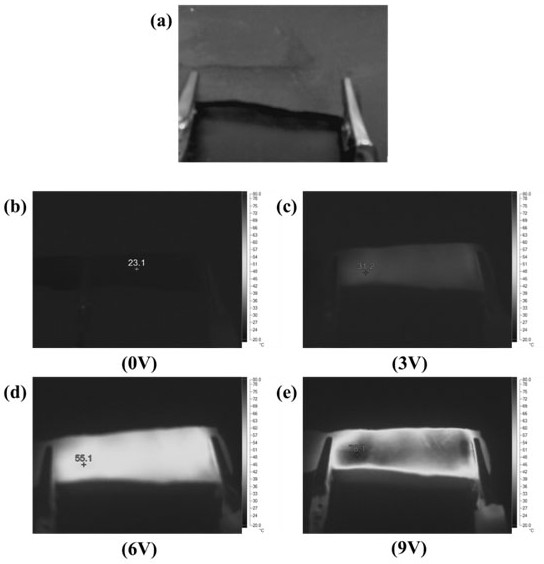

[0031]The graphene aqueous phase dispersion with a mass ratio of graphene and sericin protein of 1:1 was selected as the dispersion medium of carbon nanotubes. Add 50 g of carbon nanotube powder into 2 L of aqueous dispersion with a graphene concentration of 200 mg / mL for simple stirring to fully wet the carbon nanotube powder to obtain a premixed dispersion. At a rotational speed of 5000 rpm, the obtained premixed dispersion was sand-milled for 0.5 hours to obtain a graphene / carbon nanotube composite aqueous slurry with uniform dispersion of carbon nanotubes, and its electrical conductivity was 32000 S / m. The elastic blended fabric containing 0.5 wt% spandex and 99.5 wt% polyester fiber was soaked in 90% tannic acid aqueous solution, taken out and dried to obtain a tannic acid-coated fabric. The obtained graphene / carbon nanotube composite aqueous slurry is evenly coated on the surface of the tannic acid-coated fabric, and the fabric coated with graphene and carbon nanotube na...

Embodiment 2

[0033] The graphene aqueous phase dispersion liquid with a mass ratio of graphene and polydiallyldimethylammonium chloride of 1:1 was selected as the dispersion medium of carbon nanotubes. Add 50 g of carbon nanotube powder into 2 L of aqueous dispersion with a graphene concentration of 150 mg / mL for simple stirring to fully wet the carbon nanotube powder to obtain a premixed dispersion. At a speed of 100 rpm, the obtained premixed dispersion was subjected to planetary ball milling for 12 hours to obtain a graphene / carbon nanotube composite aqueous slurry with uniform dispersion of carbon nanotubes, and its conductivity was 11000 S / m. Soak an elastic blended fabric containing 10 wt% spandex and 90 wt% nylon in 70% tannic acid aqueous solution, take it out and dry it to obtain a tannic acid-coated fabric. The obtained graphene / carbon nanotube composite aqueous slurry is evenly coated on the surface of the tannic acid-coated fabric, and the fabric coated with graphene and carbon...

Embodiment 3

[0035] The graphene aqueous phase dispersion liquid with a mass ratio of graphene and polydiallyldimethylammonium chloride of 1:1 was selected as the dispersion medium of carbon nanotubes. Add 50 g of carbon nanotube powder into 2 L of aqueous dispersion with a graphene concentration of 100 mg / mL for simple stirring to fully wet the carbon nanotube powder to obtain a premixed dispersion. At a rotational speed of 2000 rpm, the obtained premixed dispersion was sand-milled for 2 hours to obtain a graphene / carbon nanotube composite aqueous slurry with uniform dispersion of carbon nanotubes, and its electrical conductivity was 19800 S / m. The elastic blended fabric containing 50wt% spandex and 50wt% cotton is soaked in 15% tannic acid aqueous solution, taken out and dried to obtain a tannic acid-coated fabric. The obtained graphene / carbon nanotube composite aqueous slurry is evenly coated on the surface of the tannic acid-coated fabric, and the fabric coated with graphene and carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com