Automobile connecting rod fixing clamping device

A technology for fixed clamping and automotive connecting rods, applied in positioning devices, clamping, support, etc., can solve problems such as poor adaptability, high cost, and affecting production efficiency, and achieve simple and reasonable structural design, reduce costs, and improve processing efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

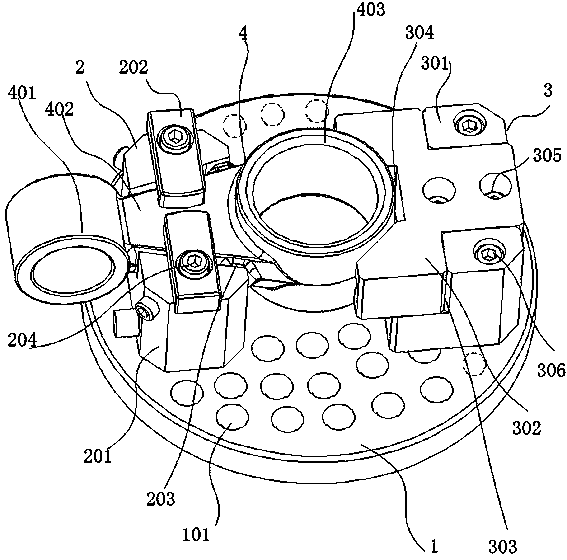

[0016] Embodiment 1: An automobile connecting rod fixing and clamping device, including a fixed base 1, a fixed clamping assembly 2, a clamping and positioning assembly 3 and a connecting rod workpiece 4, and the fixed base 1 is fixedly equipped with a fixed clamping assembly 2 and the clamping and positioning assembly 3, the connecting rod workpiece 4 is arranged between the fixed clamping assembly 2 and the clamping and positioning assembly 3, and one end of the connecting rod workpiece 4 is clamped in the fixed clamping assembly 2, and the connecting rod The other end of the rod workpiece 4 is clamped in the clamping groove of the clamping and positioning assembly 3, and the fixed base 1, the fixed clamping assembly 2, and the clamping and positioning assembly 3 are all made of stainless steel and are integrally formed.

Embodiment 2

[0017] Embodiment 2: The fixed base 1 is provided with a plurality of installation connection holes 101 evenly arranged, and the diameter of the installation connection holes 101 is 25-35 mm, and the rest of the technical solutions are the same as the embodiment 1.

Embodiment 3

[0018] Embodiment 3: The fixed clamping assembly 2 includes a limit clip 201 and a positioning block 202, the positioning block 202 is arranged on the upper end of the limit clip 201, and the fixed base 1 is penetrated by a first connecting bolt 204 The mounting holes of the positioning block 202 and the limit clamp 201 extend to the installation connection hole 101 for fixed connection. The limit clamp 201 is provided with a groove 203, and the rest of the technical solutions are the same as those in the first and second embodiments.

[0019] Embodiment 3: The clamping and positioning assembly 3 includes a clamping and positioning seat 301 and a clamping fixture 302. The clamping and positioning seat 301 is arranged on the upper end of the fixed base 1 and is fixedly connected to it. The clamping and positioning seat 301 is connected with The fixed base 1 passes through the clamping positioning seat 301 through the second connecting bolt 305 and extends to the installation con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com