Cast-molded sliding plate brick for slag stopping of converter tapping hole and production method

A technology of pouring molding and sliding bricks, which is applied in the field of refractory materials, can solve the problems that the integrity cannot meet the long-term use requirements, the complexity of the production process increases, affects the integrity and service life, etc., and achieves improved volume stability and high temperature strength Excellent, anti-flaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

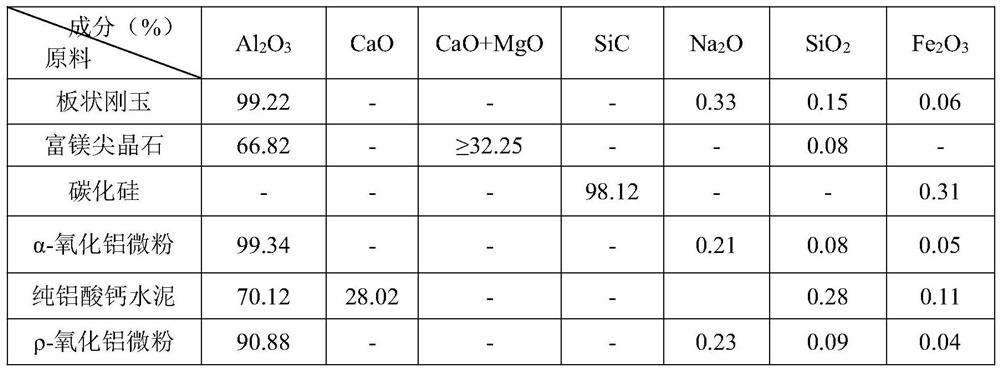

[0032] A cast-molded sliding brick for slag-stopping converter taphole, the raw materials are composed of 65% tabular corundum, 12% magnesium-rich spinel, 7% silicon carbide, and 10% alpha - Alumina micropowder, 1% pure calcium aluminate cement, 5% ρ-alumina micropowder, plus 0.05% water reducing agent of the total amount of the above raw materials.

[0033] Among them, the weight ratio of different particle sizes of tabular corundum is: particle size 1: particle size 2: particle size 3: particle size 4: particle size 4 = 10:25:15:10:5; particle size of magnesium-rich spinel ≤ 0.013mm; pure alumina The particle size of calcium cement is ≤0.045mm; the particle size of silicon carbide is ≤1mm; the particle size of α-alumina powder is D50=0.25μm, and the model is CL370; the specific surface area of ρ-alumina powder is 200m 2 / g, particle size ≤ 5 μm; the superplasticizers are high-efficiency organic superplasticizers FS10 and FW10 purchased from BASF, Germany, and the dosage ra...

Embodiment 2

[0041] A pouring-molded sliding brick for slag-stopping converter taphole, the raw materials are composed of 70% tabular corundum, 10% magnesium-rich spinel, 5% silicon carbide, and 8% alpha - Alumina micropowder, 1% pure calcium aluminate cement, 6% ρ-alumina micropowder, plus 0.05% water reducer of the total amount of the above raw materials.

[0042]The weight ratio of different particle sizes of the tabular alumina is: particle size 1: particle size 2: particle size 3: particle size 4: particle size 5=15:20:15:15:5.

[0043] The production method of this skateboard brick is with embodiment 1.

Embodiment 3

[0045] A pouring-formed sliding brick for slag-stopping converter taphole. The raw materials are composed of 78% tabular corundum, 8% magnesium-rich spinel, 3% silicon carbide, and 6% alpha - Alumina micropowder, 2% pure calcium aluminate cement, 3% ρ-alumina micropowder, plus 0.05% water reducer of the total amount of the above raw materials.

[0046] The weight ratio of different particle sizes of the tabular alumina is: particle size 1: particle size 2: particle size 3: particle size 4: particle size 5=10:25:20:13:10.

[0047] The production method of this skateboard brick is with embodiment 1.

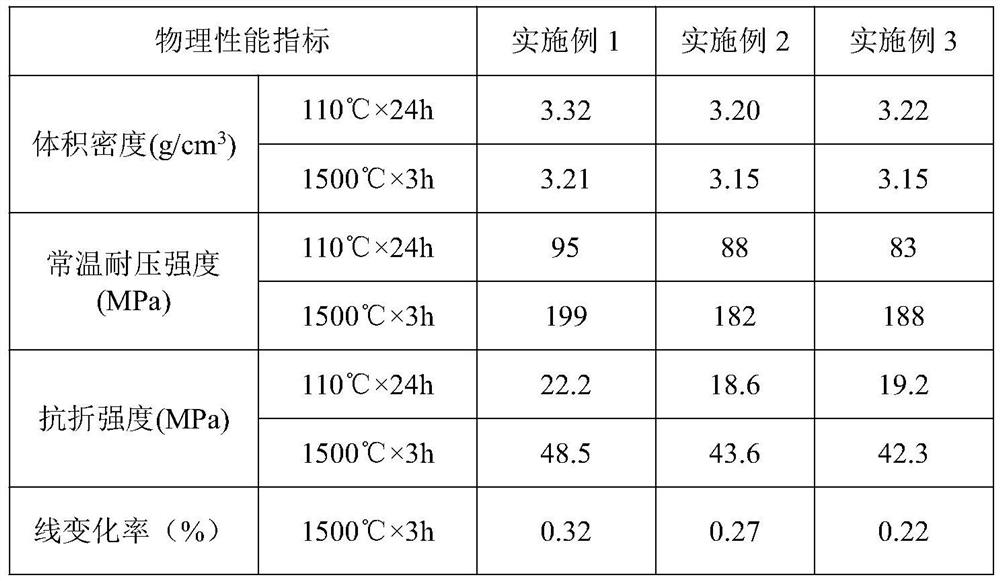

[0048] Product performance analysis of the present invention

[0049] The performance of the skateboard tile (embodiment 1-3) of the present invention is tested, and the results are shown in Table 2 below.

[0050]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com