Preparation process of cobaltosic oxide for continuous production of batteries

A preparation technology of cobalt trioxide, which is applied in battery electrodes, circuits, inorganic chemistry, etc., can solve the problems of continuous preparation process and continuous calcination with little involvement, and achieve the goal of improving the unit production capacity of equipment, improving labor efficiency and reducing costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

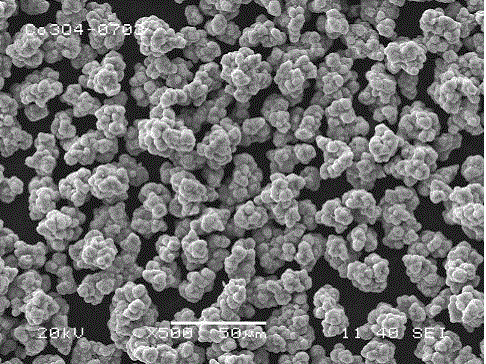

Image

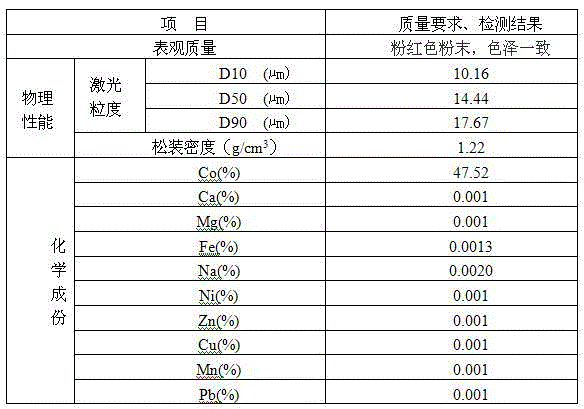

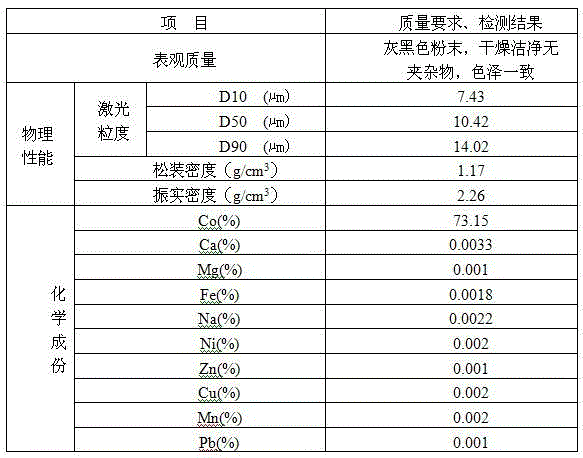

Examples

Embodiment Construction

[0020] In order to make it easy to understand the technical means, creative features, objectives and effects achieved by the present invention, the process of the present invention will be further explained below.

[0021] A preparation process for continuous production of cobalt tetroxide for batteries uses the following steps to realize the production of cobalt tetroxide:

[0022] (1) Preparation of cobalt solution: using cobalt ore as raw material, after sulfuric acid leaching, oxidation and iron removal, extraction and impurity removal, and cobalt, nickel and magnesium separation, a cobalt solution containing 100-140g / l of cobalt is obtained;

[0023] (2) Preparation of precipitant: select one of qualified sodium bicarbonate, sodium carbonate, ammonium bicarbonate, and ammonium carbonate, dissolve it in water, and prepare a precipitant solution with a concentration of 100-300g / l;

[0024] (3) Lithium carbonate synthesis: the cobalt solution and the precipitant solution are continuo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com