Transparent super-hydrophobicity wood coating and preparation method thereof

A super-hydrophobic, wood coating technology, applied in polyester coatings, polyurea/polyurethane coatings, coatings, etc., can solve the problems of easy cracking, poor stability, and short service life of the coating film, and achieve good applicability, size Adjustable, process-controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

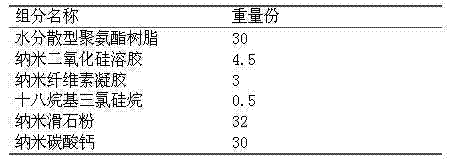

[0020] A kind of transparent superhydrophobic coating of the present embodiment

[0021]

[0022] Its preparation method: comprises the steps:

[0023] 1) Add the main resin and filler into the stirring tank, stir evenly to make a slurry;

[0024] 2) Grinding the above slurry with a sand mill;

[0025] 3) Add low surface energy substances, add supported nano-silica sol, and mix thoroughly with ultrasonic waves for 30 minutes to obtain a transparent superhydrophobic coating.

[0026] The preparation method of described nano silica sol: comprise the steps:

[0027] (1) Stir and mix 5ml of ammonia water and 50ml of absolute ethanol evenly, add 5ml of tetraethyl orthosilicate dropwise while stirring, and then continue to stir at room temperature to obtain stable nano-silica particles with uniform sizes the sol;

[0028] (2) Add microcrystalline cellulose to 60% sulfuric acid solution and stir at 50°C to hydrolyze the microcrystalline cellulose to produce nanocellulose with ...

Embodiment 2

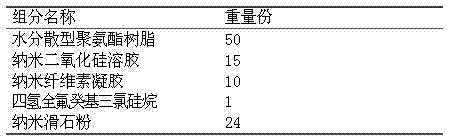

[0031] A kind of transparent superhydrophobic coating of the present embodiment

[0032]

[0033] Its preparation method is the same as implementation 1.

Embodiment 3

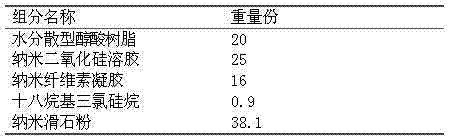

[0035] A kind of transparent superhydrophobic coating of the present embodiment

[0036]

[0037] Its preparation method is the same as implementation 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com