Modified talcpowder and preparation method thereof

A talcum powder and modification technology, which is applied in the treatment of dyed low molecular weight organic compounds, fibrous fillers, dyed organosilicon compounds, etc. Oil absorption rate, high sedimentation volume, the effect of improving the modification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] Preparation of polyol laurate

[0041]Preparation of glyceryl monolaurate: Mix 200.0g lauric acid and 92.0g glycerin, add catalyst sodium hydroxide, heat and stir, control the temperature at 200°C, react for 4h, after the reaction is completed, filter to obtain glyceryl monolaurate.

[0042] Preparation of butanediol monolaurate: mix 200.0g lauric acid with 90.0g 1,2-butanediol, add catalyst sodium hydroxide, heat and stir, control the temperature at 210°C, react for 3h, the reaction is completed, filter, In butylene glycol monolaurate.

[0043] Preparation of pentaerythritol monolaurate: Mix 200.0 g of lauric acid and 136.0 g of pentaerythritol, add catalyst sodium hydroxide, heat and stir, control the temperature at 180° C., react for 5 hours, complete the reaction, and filter to obtain pentaerythritol monolaurate.

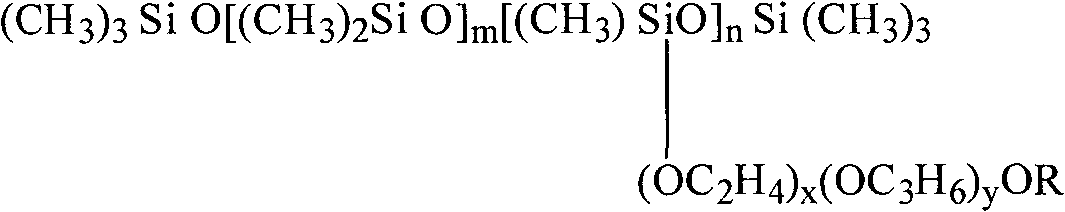

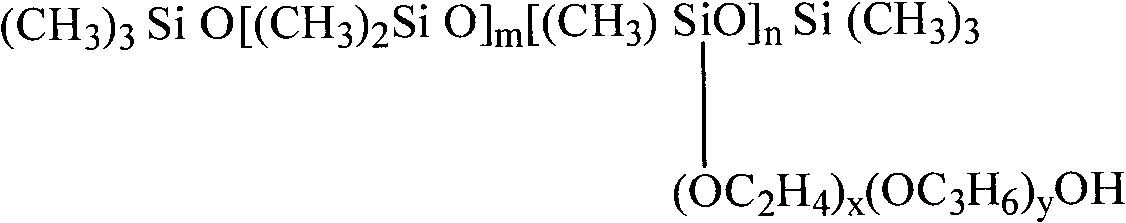

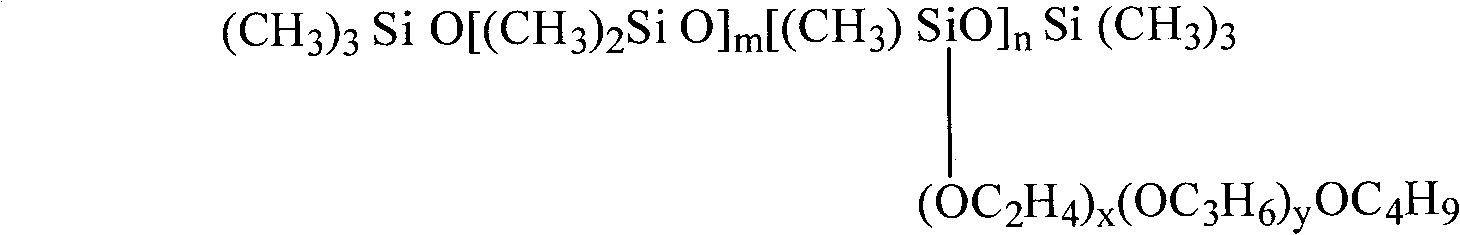

[0044] Preparation of silicone / polyether copolymer

[0045] The preparation of organosilicon / polyether copolymer A: add 200g of hydrogen-containing sil...

Embodiment 1

[0049] The modified talcum powder is prepared as follows:

[0050] 1) Weigh 1000g of the dried talcum powder material and put it into a temperature-controllable high mixer;

[0051] 2) Weigh 10.0 g of modifier propylene glycol laurate and 10.0 g of silicone / polyether copolymer A;

[0052] 3) Add the weighed modifier evenly into the talcum powder in the high mixer, and stir for 15 minutes at a temperature of 100°C;

[0053] 4) Take out the modified talcum powder.

Embodiment 2

[0055] The modified talcum powder is prepared as follows:

[0056] 1) Weigh 1000g of the dried talcum powder material and put it into a temperature-controllable high mixer;

[0057] 2) Weigh 4.0 g of modifier monolaurin and 6.0 g of silicone / polyether copolymer B;

[0058] 3) Add the weighed modifier evenly into the talcum powder in the high mixer, and stir for 20 minutes at a temperature of 110°C;

[0059] 4) Take out the modified talcum powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average relative molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com