Graphene modified polyaniline conductive coating and preparation method thereof

A technology of graphene modification and conductive coatings, applied in conductive coatings, epoxy resin coatings, coatings, etc., can solve the problems of insufficient electrical conductivity, poor bonding performance between coatings and substrates, and low service life, and achieve good application value , Improve electrical conductivity and mechanical properties, enhance the effect of bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

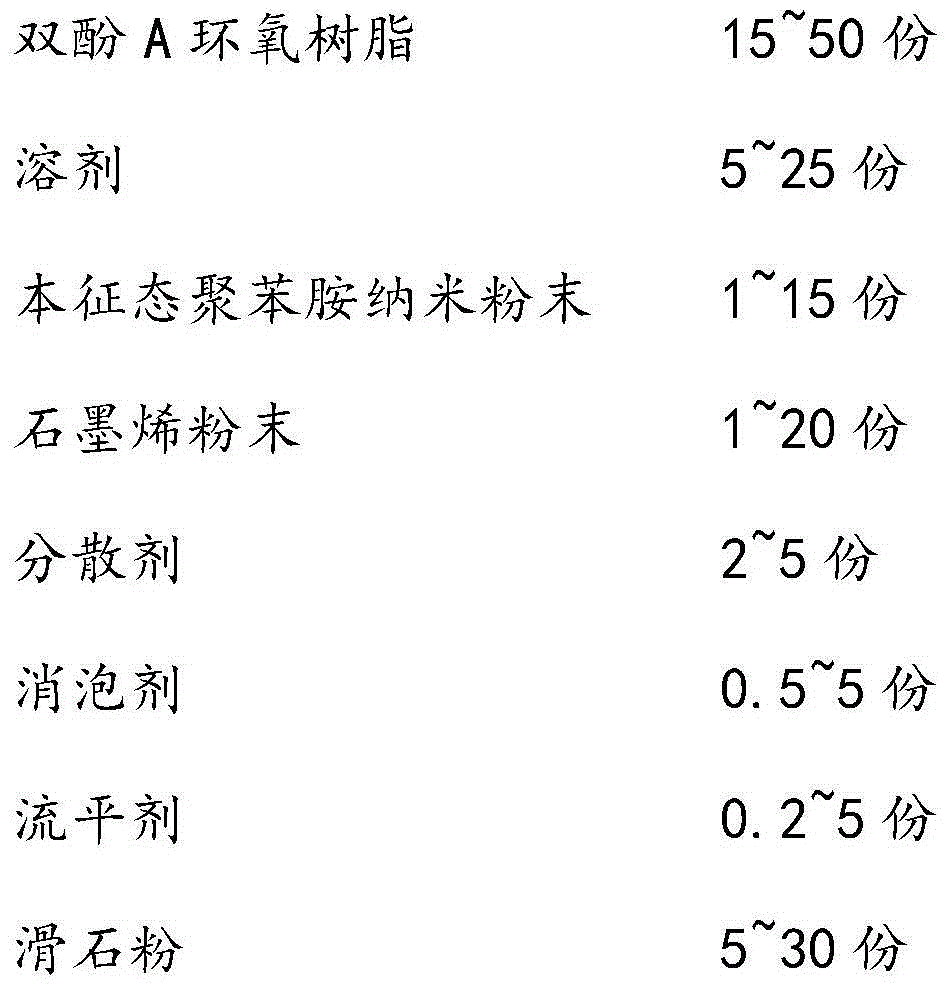

[0032] A graphene-modified polyaniline conductive coating, the components and parts by mass of the coating are:

[0033] A component:

[0034]

[0035] B component:

[0036]

[0037] Wherein, parts by mass are relative parts by mass ratio, for example, 1 part is 0.1g, 0.2g, 0.5g, 0.8g, 1g, 2g, 5g, 10g, 20g, 25g, 50g, 70g, 100g, 200g, 500g or 1000g etc.

[0038] Among them, bisphenol A epoxy resin is a high molecular compound refined by condensation of bisphenol A and epichlorohydrin under alkaline conditions, washing with water, and solvent removal. Preferably, the bisphenol A epoxy resin is any one or more of E44, E51 and E35 types. 44 means the average epoxy value is 0.44. For example, the bisphenol A epoxy resin is E44, E51 or E35; as another example, the bisphenol A epoxy resin is E44 and E51, and the mass ratio is 1:1; as another example, the bisphenol A Epoxy resins are E44, E51 and E35 types, and their mass ratio is 1:2:1.

[0039] Preferably, the solvent is...

Embodiment 2

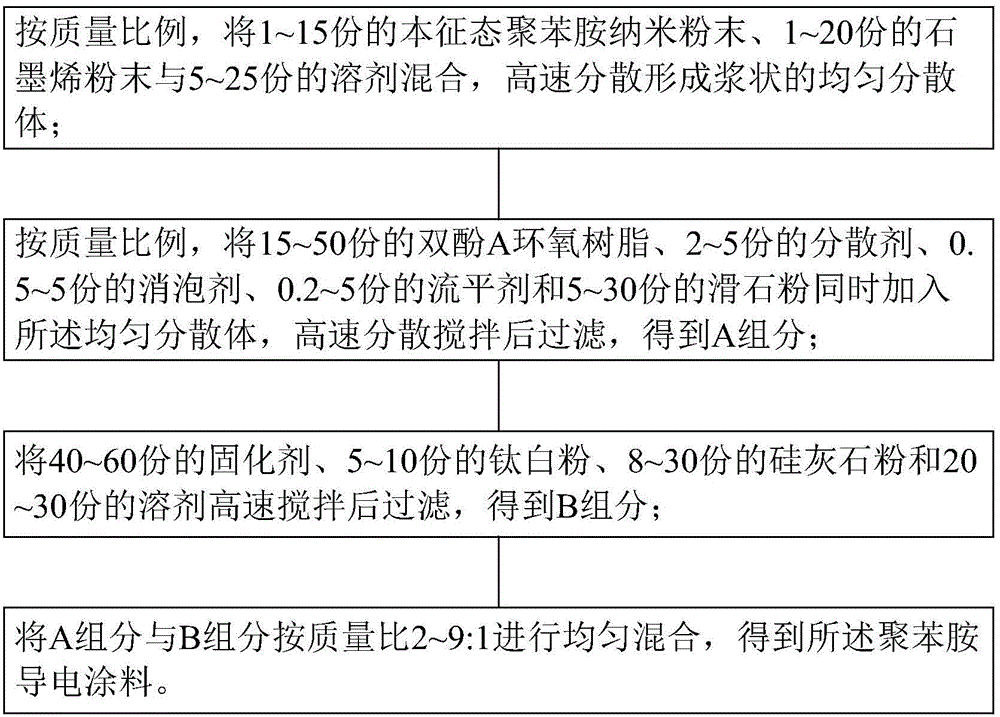

[0052] The following illustrates the preparation of the polyaniline conductive coating of above-mentioned embodiment, as figure 1 Shown, a kind of preparation method of the polyaniline conductive coating of graphene modification, it may further comprise the steps:

[0053] According to the mass ratio, mix 1-15 parts of intrinsic polyaniline nano powder, 1-20 parts of graphene powder and 5-25 parts of solvent, and disperse at high speed to form a slurry-like uniform dispersion; wherein, the high-speed Dispersion is enough to achieve uniform dispersion, for example, including stirring with a stirrer at a speed of 100 rpm to 2000 rpm, and for another example, stirring at a speed of 200 rpm to 500 rpm.

[0054] According to the mass ratio, mix 15-50 parts of bisphenol A epoxy resin, 2-5 parts of dispersant, 0.5-5 parts of defoamer, 0.2-5 parts of leveling agent and 5-30 parts of talc powder At the same time, add the uniform dispersion, disperse and stir at a high speed and then f...

Embodiment 3

[0058] Continue to exemplify the preparation of the polyaniline conductive coating of above-mentioned embodiment below, a kind of preparation method of the polyaniline conductive coating of graphene modification, concrete operation steps are:

[0059] Mix intrinsic polyaniline nanopowder, graphene powder and solvent, and disperse at a high speed for 1 to 2 hours to form a slurry-like uniform dispersion; for example, mix intrinsic polyaniline nanopowder, graphene powder, surfactant and solvent . For example, stirring at high speed for 1, 1.2, 1.3, 1.5, 1.8, or 2 hours results in a dispersion that is relatively uniformly dispersed and forms a slurry, that is, the homogeneous dispersion.

[0060] Add bisphenol A epoxy resin, dispersant, defoamer, leveling agent and talcum powder to the above stable dispersion at the same time, continue to stir at high speed for 2 to 3 hours, and filter with a filter to obtain component A; for example, high-speed stirring 2, 2.2, 2.5, 2.8 or 3 ho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com