Rubber matrix for inflating valve

A valve and rubber material technology, applied in the field of valve rubber material, can solve the problems of cumbersome production process, large investment burden of production enterprises, poor ventilation and easy fire hazards, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

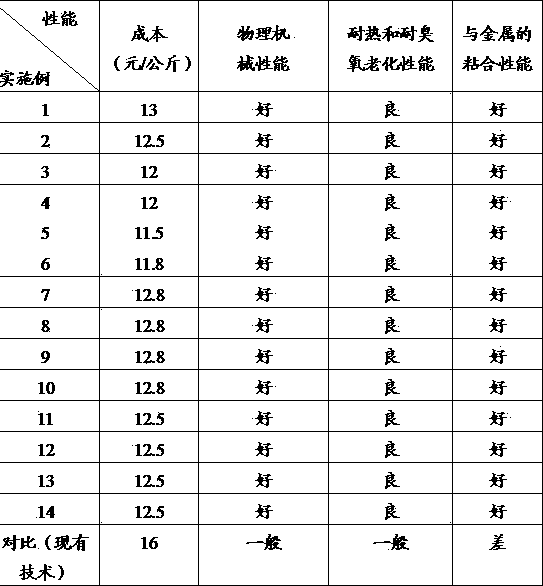

Examples

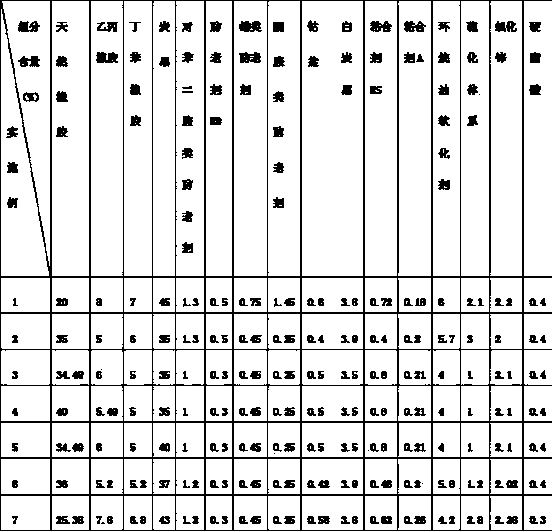

Embodiment 1

[0024] A valve rubber material, comprising the following components by weight percentage:

[0025] Natural rubber 20%;

[0026] Ethylene propylene rubber 8%;

[0027] SBR 7%;

[0028] Carbon black 45%;

[0029] p-phenylenediamine antioxidant 1.3%;

[0030] Anti-aging agent RD 0.5%;

[0031] Wax antioxidant 0.75%;

[0032] Ketoamine antioxidant BLE-W 1.45%;

[0033] Cobalt salt 0.6%;

[0034] Silica 3.8%;

[0035] Binder RS 0.72%;

[0036] Adhesive A 0.18%;

[0037] Naphthenic oil softener 6%;

[0038] Vulcanization system 2.1%;

[0040] Stearic Acid 0.4%.

[0041] The preparation steps of the above-mentioned valve sizing material are as follows:

[0042] (1) Prepare materials, prepare the natural rubber, ethylene-propylene rubber, carbon black, p-phenylenediamine anti-aging agent, cobalt salt system, white carbon black, binder RS, binder A, ring Paraffin oil softener, vulcanization system, zinc oxide, stearic acid and styrene-butadien...

Embodiment 2

[0050] All the other are identical with described embodiment 1, and difference is that above-mentioned valve compound comprises the following components by weight percentage:

[0051] Natural rubber 35%;

[0052] Ethylene propylene rubber 5%;

[0053] SBR 6%;

[0054] Carbon black 35%;

[0055] p-phenylenediamine antioxidant 1.3%;

[0056] Anti-aging agent RD 0.5%;

[0057] Wax antioxidant 0.45%;

[0058] Ketoamine antioxidant BLE-W 0.25%;

[0059] Cobalt salt 0.4%;

[0060] Silica 3.9%;

[0061] Binder RS 0.4%;

[0062] Adhesive A 0.2%;

[0063] Naphthenic oil softener 5.7%;

[0064] Vulcanization system 3%;

[0066] Stearic Acid 0.4%.

Embodiment 3

[0068] All the other are identical with described embodiment 1, and difference is that above-mentioned valve compound comprises the following components by weight percentage:

[0069] Natural rubber 39.49%;

[0070] Ethylene propylene rubber 6%;

[0071] SBR 5%;

[0072] Carbon black 35%;

[0073] p-phenylenediamine antioxidant 1%;

[0074] Anti-aging agent RD 0.3%;

[0075] Wax antioxidant 0.45%;

[0076] Ketoamine antioxidant BLE-W 0.25%;

[0077] Cobalt salt 0.5%;

[0078] Silica 3.5%;

[0079] Binder RS 0.8%;

[0080] Adhesive A 0.21%;

[0081] Softener 4%;

[0082] Vulcanization system 1%;

[0083] Zinc oxide 2.1 %;

[0084] Stearic Acid 0.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com