High-hardness low-compression-deformation self-lubricating rubber bush used in vehicle transverse stabilizing bar

A technology of stabilizer bars and rubber bushings, applied in the field of rubber parts, can solve problems such as poor durability, dimensional deformation, and loose fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

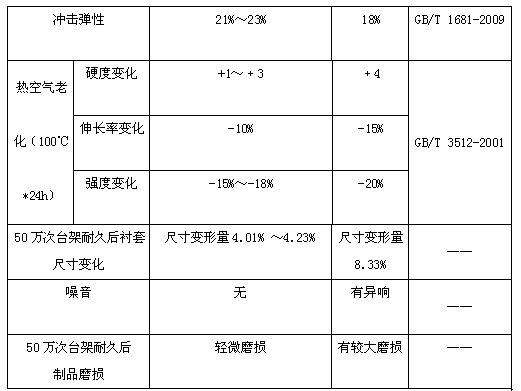

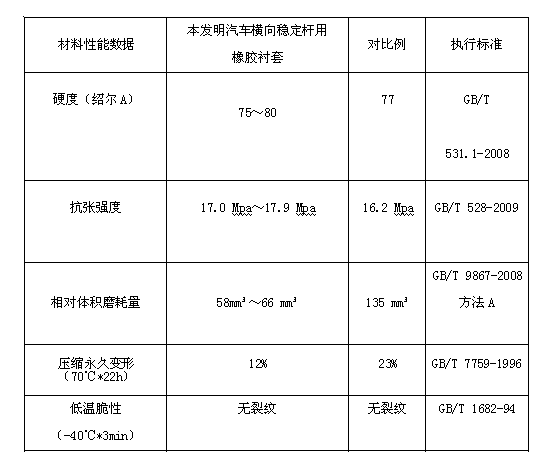

[0017] Example 1, raw materials were weighed according to the following parts by mass: butadiene rubber (high cis structure): 50Kg, styrene-butadiene rubber (oil-containing): 65 Kg, zinc oxide: 5 Kg, stearic acid: 2 Kg, silane coupling Antiaging agent Si-69: 1 Kg, antiaging agent RD: 2 Kg, antiaging agent AW-P: 3 Kg, antiaging agent 4010NA: 1.5 Kg, flow aid Disperaid4A: 2 Kg, paraffin wax FLY-3: 5 Kg, oleic acid amide CP: 10 Kg, carbon black N330: 55 Kg, carbon black N774: 20 Kg, aromatic oil 790: 3 Kg, sulfur: 1 Kg, accelerator CBS: 1 Kg, accelerator TMTD: 0.5 Kg, anti-scorch agent CTP: 0.1 Kg.

Embodiment 2

[0018] Example 2, raw materials were weighed according to the following parts by mass: butadiene rubber (high cis structure): 70Kg, styrene-butadiene rubber (oil-containing): 40 Kg, zinc oxide: 8 Kg, stearic acid: 1 Kg, silane coupling Agent Si-69: 1.5 Kg, antiaging agent RD: 3 Kg, antiaging agent AW-P: 2 Kg, antiaging agent 4010NA: 1 Kg, flow aid Disperaid4A: 3 Kg, paraffin wax FLY-3: 3 Kg, oleic acid amide CP: 20 Kg, carbon black N330: 75 Kg, carbon black N774: 10 Kg, aromatic oil 790: 7 Kg, sulfur: 1.5 Kg, accelerator CBS: 1.5 Kg, accelerator TMTD: 0.3 Kg, anti-scorch agent CTP: 0.3 Kg.

Embodiment 3

[0019] Example 3, raw materials were weighed according to the following parts by mass: butadiene rubber (high cis structure): 60Kg, styrene-butadiene rubber (oil-containing): 55 Kg, zinc oxide: 6 Kg, stearic acid: 3 Kg, silane coupling Antiaging agent Si-69: 2 Kg, antiaging agent RD: 1 Kg, antiaging agent AW-P: 1 Kg, antiaging agent 4010NA: 2 Kg, flow aid Disperaid4A: 5 Kg, paraffin wax FLY-3: 1 Kg, oleic acid amide CP: 15 Kg, carbon black N330: 60 Kg, carbon black N774: 30 Kg, aromatic oil 790: 10 Kg, sulfur: 2 Kg, accelerator CBS: 1.3 Kg, accelerator TMTD: 0.8 Kg, anti-scorch agent CTP: 0.2 Kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com