Polyethylene isolating film reusable in tire production and preparation method of polyethylene isolating film

A technology of polyethylene and isolation film, which is applied in the direction of chemical instruments and methods, layered products, synthetic resin layered products, etc. It can solve the problems of large differences in material properties and easy delamination, and achieve good bonding and compatibility Good, good mechanical properties and the effect of oxygen barrier properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

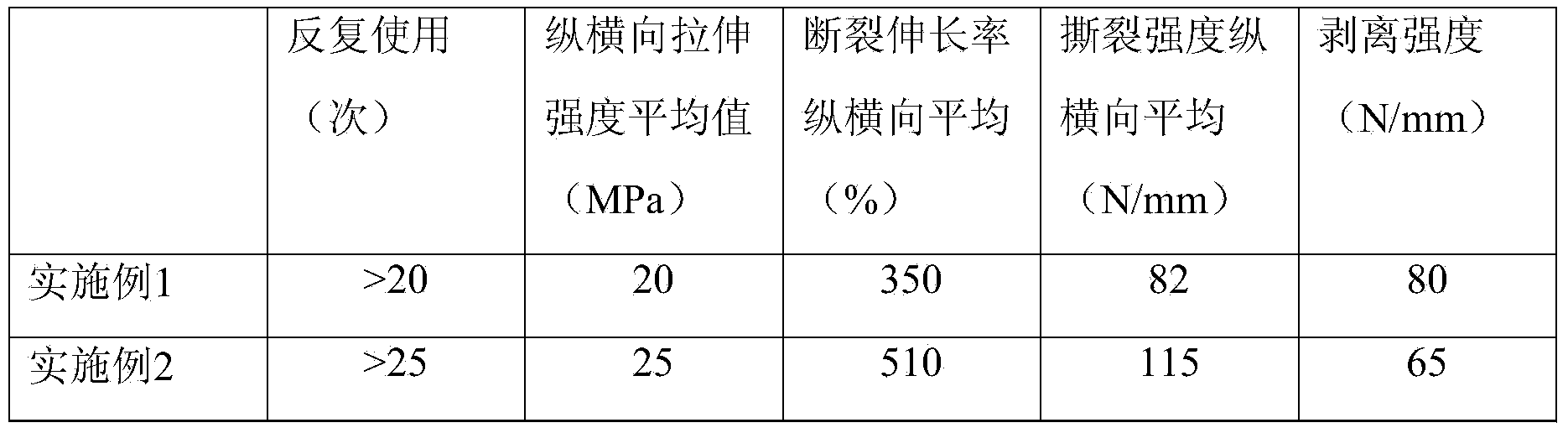

Examples

Embodiment 1

[0025] Polyethylene isolation film used for repeated use in tire production, including outer film, middle film and inner film; the thickness ratio of the three films is 3:2:3 in turn;

[0026] The total thickness of the outer layer film, the middle layer film and the inner layer film is 30 μm.

[0027] The polyethylene isolation film used for repeated use in tire production is calculated in parts by weight: the outer film and the inner film are blends of low-density polyethylene and linear low-density polyethylene, both of which are 30 parts; The middle layer film is a blend of linear low density polyethylene and an oxygen absorber, 20 parts.

[0028] In the outer film and the inner film, the weight ratio of low density polyethylene to linear low density polyethylene is 1:1; in the middle layer film, the weight ratio of linear low density polyethylene to oxygen absorber is 10:1.

[0029] The oxygen absorbent is iron powder with a mass fraction of 90% and electrolyte with 10%....

Embodiment 2

[0039] Polyethylene isolation film used for repeated use in tire production, including outer film, middle film and inner film; the thickness ratio of the three films is 4:2:4 in sequence;

[0040] The total thickness of the outer layer film, the middle layer film and the inner layer film is 150 μm.

[0041] The polyethylene isolation film used for repeated use in tire production is calculated in parts by weight: the outer film and the inner film are blends of low-density polyethylene and linear low-density polyethylene, both of which are 35 parts; The middle layer film is a blend of linear low density polyethylene and oxygen absorbing agent, which is 35 parts.

[0042] In the outer film and the inner film, the weight ratio of low density polyethylene to linear low density polyethylene is 6:1; in the middle layer film, the weight ratio of linear low density polyethylene to oxygen absorber is 60:1.

[0043] The oxygen absorbent is iron powder with a mass fraction of 95% and ele...

Embodiment 3

[0053]Polyethylene isolation film used for repeated use in tire production, including outer film, middle film and inner film; the thickness ratio of the three films is 4:2:4 in sequence;

[0054] The total thickness of the outer film, the middle film and the inner film is 100 μm.

[0055] The polyethylene isolation film used for repeated use in tire production is calculated in parts by weight: the outer film and the inner film are blends of low-density polyethylene and linear low-density polyethylene, both of which are 40 parts; The middle layer film is a blend of linear low density polyethylene and an oxygen absorber, 40 parts.

[0056] In the outer film and the inner film, the weight ratio of low density polyethylene to linear low density polyethylene is 10:1; in the middle layer film, the weight ratio of linear low density polyethylene to oxygen absorber is 100:1.

[0057] The oxygen absorbent is iron powder with a mass fraction of 98% and electrolyte with 2%.

[0058] Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com