Flexible environment-friendly polyolefin cable material and preparation method of flexible environment-friendly polyolefin cable material

A polyolefin cable material, environmental protection technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of large corrosion and high price of instruments and equipment, and achieve the effects of reducing processing costs, improving flexibility, and improving oxygen index.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

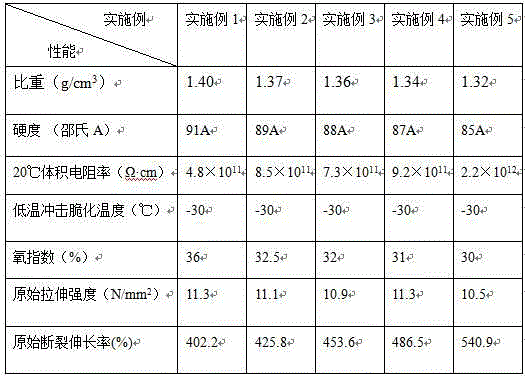

Examples

Embodiment 1

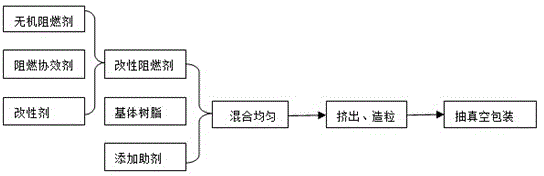

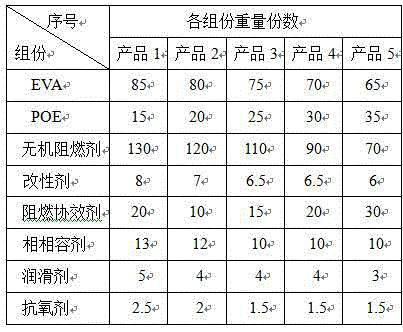

[0026] A kind of processing method of soft environment-friendly polyolefin cable material, such as figure 1 As shown, weigh polyolefin powder and silane according to the formula, mix them uniformly as modifiers, add modifiers, flame retardants, and flame retardant synergists into a high-speed mixer, and stir at a high speed at 40-45°C 20 to 25 minutes for surface activation treatment; weigh other components according to the formula, together with the modified flame retardant and flame retardant synergist, and stir in the mixer at a low speed for 3 to 5 minutes; send the stirred raw materials into a forced In the twin-screw extruder of the feeding system, it can be plasticized, extruded, granulated, and packaged. The temperature of each zone of the screw is between 120 and 145°C. The product formula (number of servings) is shown in Table 1.

[0027] Table 1 Product formula table

[0028]

[0029] in,

[0030] In product 1: EVA is composed of 70 parts of EVA with VA conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com