Preparation method of reinforced hydrogenated butyronitrile composite material

A technology of hydrogenated nitrile and composite materials, which is applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of imperfect dispersion and inability to solve problems higher than 150°C, and achieve excellent aging resistance , good sealing effect, excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] A preparation method for reinforced hydrogenated nitrile butadiene composite material, the steps are as follows: firstly put hydrogenated nitrile butadiene rubber in an open mill for mastication, after the hydrogenated nitrile butadiene rubber is covered with rolls, add stearic acid, metal oxide, anti-aging Mix the agent on the open mill for 5 minutes, then add the reinforcing agent and mix evenly, then add the vulcanizing agent and the vulcanization auxiliary agent and mix evenly, and then thin the lower sheet to obtain the mixed rubber; put the mixed mixed rubber in the Under the conditions of 170°C, 20min curing time and 15 MPa curing pressure, the hydrogenated nitrile vulcanizate was vulcanized by a flat vulcanizer.

[0018] Use hydrogenated nitrile rubber with a degree of hydrogenation greater than 96% and an acrylonitrile content of 44%;

[0019] The reinforcing agent refers to one or a mixture of carbon black or zinc acrylate; further, the zinc acrylate is zinc h...

Embodiment 1

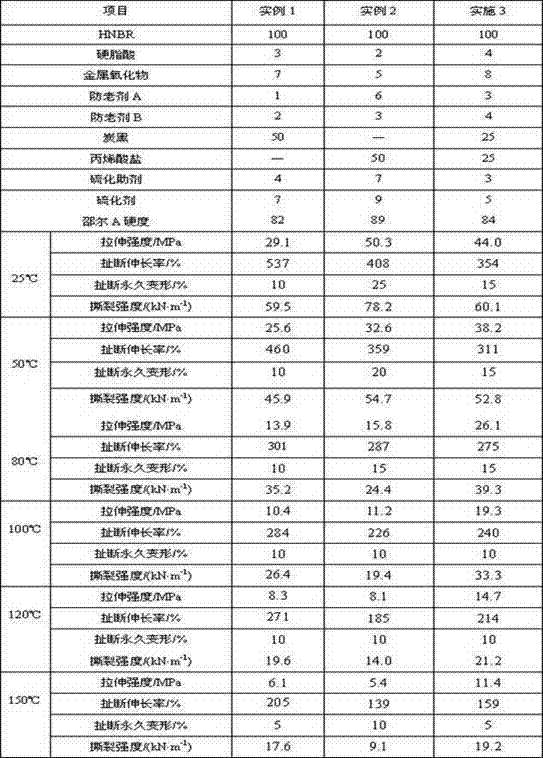

[0026] Put 100 parts of hydrogenated nitrile rubber into the open mill for mastication, add 3 parts of stearic acid, 7 parts of zinc oxide, 1 part of anti-aging agent RD, and 2 parts of anti-aging agent 445 in turn after wrapping the rolls, and knead on the open mill 5min, then add 50 parts of carbon black and knead evenly, add 4 parts of triallyl isocyanurate and 7 parts of dicumyl peroxide and knead evenly, pack into triangular bags, and make a kneading glue. After the mixed rubber is cooled for 24 hours, put it into the mold and vulcanize it in a flat vulcanizer. The vulcanization temperature is 170°C, the vulcanization time is 15 minutes, and the vulcanization pressure is 15 MPa. The properties are shown in Table 1, wherein the carbon black is carbon black 330.

Embodiment 2

[0028] Put 100 parts of hydrogenated nitrile rubber into the open mill for masticating, add 3 parts of stearic acid, 5 parts of zinc oxide, 1 part of anti-aging agent RD, and 2 parts of anti-aging agent 445 in turn after wrapping the rolls and mix on the open mill Refining for 5 minutes, then adding 50 parts of zinc hydroxide monomethacrylate and mixing evenly, adding 7 parts of triallyl isocyanurate and 9 parts of dicumyl peroxide and mixing evenly, then making triangular bags, Botong The next piece is made into rubber compound. After the mixed rubber is cooled for 24 hours, put it into the mold and vulcanize it in a flat vulcanizer. The vulcanization temperature is 170°C, the vulcanization time is 15 minutes, and the vulcanization pressure is 15 MPa. The properties are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com