High-performance EPDM (Ethylene-Propylene-Diene Monomer)/PP(Polypropylene)/NBR(Nitrile -Butadiene Rubber) ternary

A thermoplastic elastomer and dynamic vulcanization technology, applied in the field of polymer materials, can solve the problems of oil resistance, wear resistance and poor air tightness, and achieve the effect of good oil resistance and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

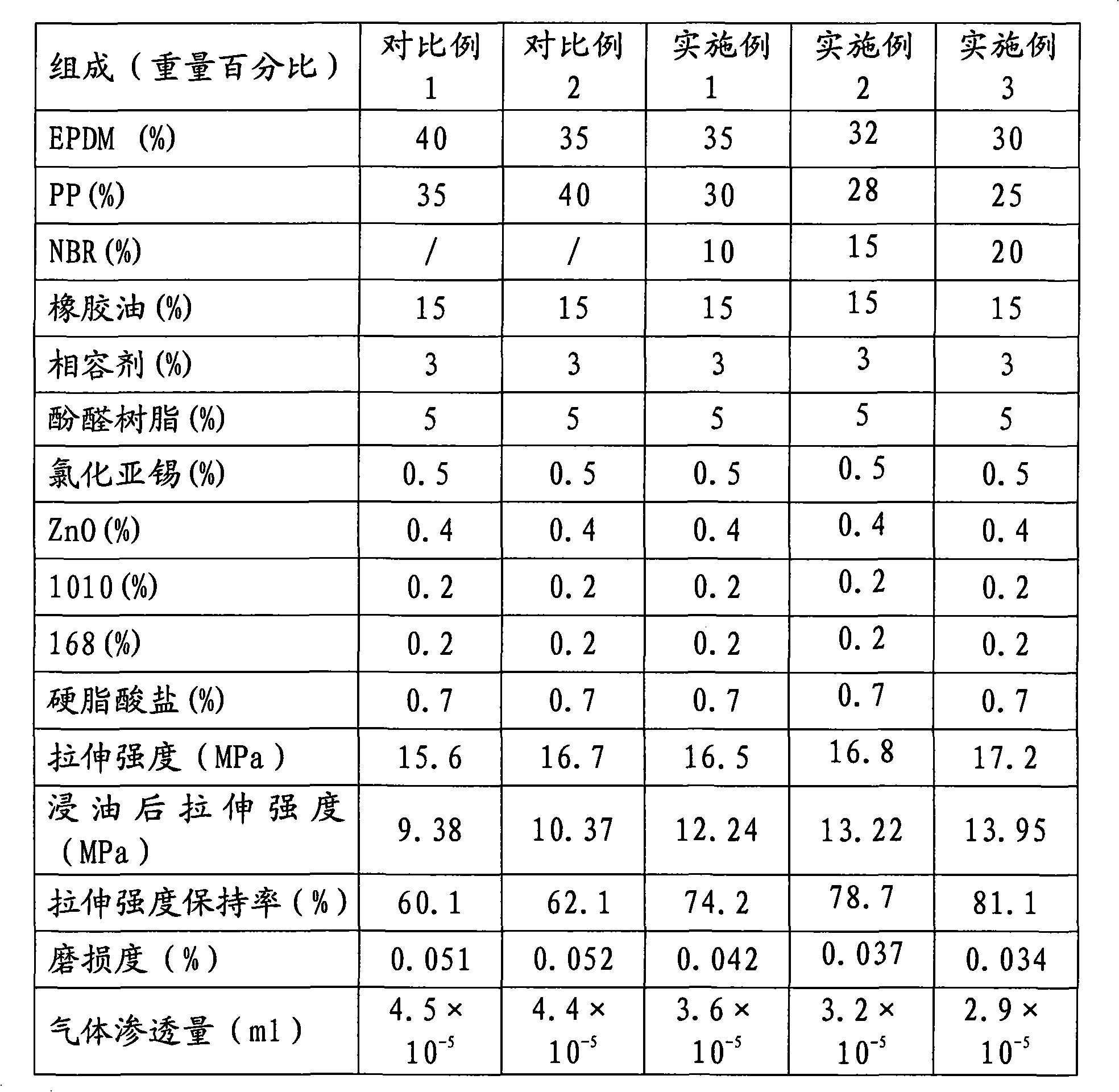

[0049] EPDM is 35% by weight (the following are all weight ratios), PP 30%, NBR 10%, PP-g-MAH 3%, weighed and poured into the mixer, stir evenly, and then press 5% of phenolic resin beads, 0.5% stannous chloride, 0.4% zinc oxide, 1010 / 1680.2 / 0.2%, 0.7% zinc stearate were weighed, poured into a blender and stirred evenly. Add the mixed materials into the hopper of the twin-screw extruder, and add 15% rubber oil into the extruder from the plasticizing section of the extruder through a liquid metering pump, melt and blend, extrude and granulate to form a compound Material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 160°C; zone 2: 170°C; zone 3: 180°C; zone 4: 170°C; head: 180°C; residence time 2-3min. The pressure is 14MPa.

Embodiment 2

[0051] EPDM is 32% by weight (the following are all weight ratios), PP 28%, NBR 15%, PP-g-MAH 3%, weighed and poured into the mixer, stir evenly, and then press 5% of phenolic resin beads, 0.5% stannous chloride, 0.4% zinc oxide, 1010 / 1680.2 / 0.2%, 0.7% zinc stearate were weighed, poured into a blender and stirred evenly. Add the mixed materials into the hopper of the twin-screw extruder, and add 15% rubber oil into the extruder from the plasticizing section of the extruder through a liquid metering pump, melt and blend, extrude and granulate to form a compound Material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 160°C; zone 2: 170°C; zone 3: 180°C; zone 4: 170°C; head: 180°C; residence time 2-3min. The pressure is 14MPa.

Embodiment 3

[0053] EPDM is 30% by weight (the following are all weight ratios), PP 25%, NBR 20%, PP-g-MAH 3%, weighed and poured into the mixer, stir evenly, and then press phenolic resin 5%, chlorine 0.5% stannous oxide, 0.4% zinc oxide, 1010 / 1680.2 / 0.2%, 0.7% zinc stearate were weighed, poured into a blender and stirred evenly. Add the mixed materials into the hopper of the twin-screw extruder, and add 15% rubber oil into the extruder from the plasticizing section of the extruder through a liquid metering pump, melt and blend, extrude and granulate to form a compound Material. Among them, the temperature settings of each heating zone of the screw are: zone 1 temperature: 160°C; zone 2: 170°C; zone 3: 180°C; zone 4: 170°C; head: 180°C; residence time 2-3min. Pressure is 14MPa Performance test:

[0054] Tensile strength is tested according to the GB / T 528 standard. The sample type is a type sample. The stretching speed is 200mm / min;

[0055] The oil resistance test is carried out acco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com