Magnetic composite material surface imprinting thermosensitive adsorbent, and preparation method and application thereof

A magnetic composite material and surface imprinting technology, applied in the direction of solid adsorbent liquid separation, separation method, chemical instrument and method, etc., can solve the problems of volume shrinkage, low adsorption capacity of rigid tea and limit wide application, etc., achieve rapid separation, reduce Effects of nonspecific adsorption, good magnetic and thermal response properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

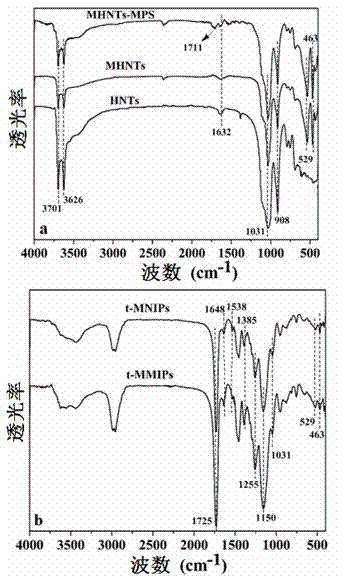

[0027] (1) Halloysite nanotubes (HNTs) activation method

[0028] Blocky halloysite nanotubes are ground and crushed through 100 sieves, and at 100 o Calcined at high temperature for 18 hours, then the halloysite nanotubes were 70 h in concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:3 o C was refluxed for 6.0h, and the final product was washed with twice distilled water to neutrality, at 60 o Dry at C for later use.

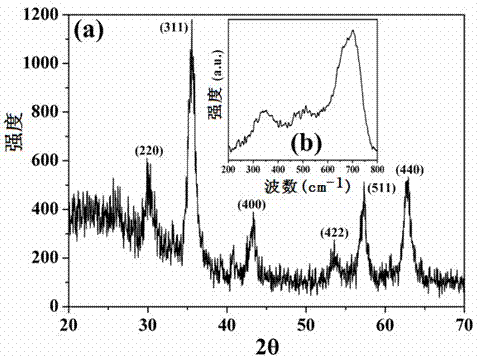

[0029] (2) Preparation of magnetic halloysite nanotube composites (MHNTs)

[0030] Activated halloysite nanotubes were mixed with ferric chloride hexahydrate (FeCl 3 ·6H 2 O), sodium acetate (NaAc) is ultrasonically dissolved and dispersed in ethylene glycol according to the mass ratio of 0.6: 0.25: 1.5, the amount of ethylene glycol added follows the ratio of 80ml per 1.0g of halloysite nanotubes, and the ultrasonic time is 2.0h; then, according to the ratio of 1.2g polyethylene glycol (PEG-1000) per 1.0g halloysite nanotube...

Embodiment 2

[0035] (1) Halloysite nanotubes (HNTs) activation:

[0036] Blocky halloysite nanotubes were ground and crushed through a 100 sieve, and the oC Calcined at high temperature for 24h, then the halloysite nanotubes were 80% in concentrated sulfuric acid and concentrated nitric acid with a volume ratio of 1:4 o C was refluxed for 10h, and the final product was washed to neutrality with double distilled water, at 60 o Dry at C for later use.

[0037] (2) Preparation of magnetic halloysite nanotube composites (MHNTs):

[0038] Activated halloysite nanotubes were mixed with ferric chloride hexahydrate (FeCl 3 ·6H 2 O), sodium acetate (NaAc) is ultrasonically dissolved and dispersed in ethylene glycol according to the ratio of mass ratio 1.0: 0.4: 2.5, the amount of ethylene glycol added follows the ratio of 100ml per 1.0g of halloysite nanotubes, ultrasonic time 5.0h; then, according to the ratio of 1.8g polyethylene glycol (PEG-1000) per 1.0g halloysite nanotubes, add polyethy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com