Method for preparing hydrogenated nitrile rubber and chloroprene rubber blended vulcanized rubber

A technology for hydrogenated nitrile rubber and chloroprene rubber is applied in the field of vulcanizate preparation, which can solve the problems of poor mechanical properties and accelerated vulcanization speed of hydrogenated nitrile butadiene rubber, and achieve the improvement of poor mechanical properties, accelerated vulcanization speed, and excellent resistance to heat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

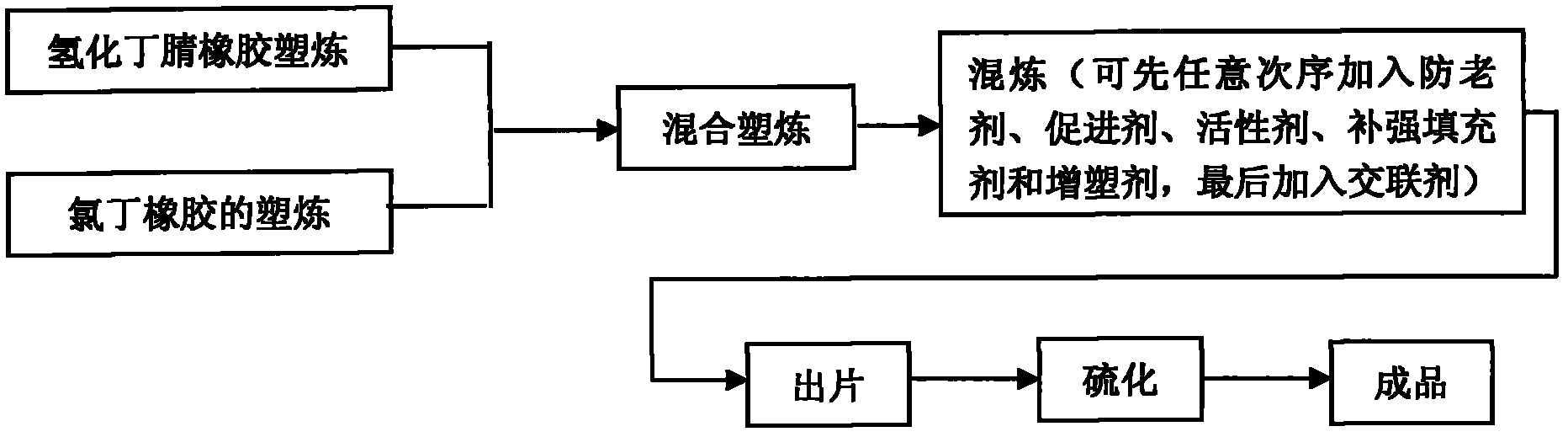

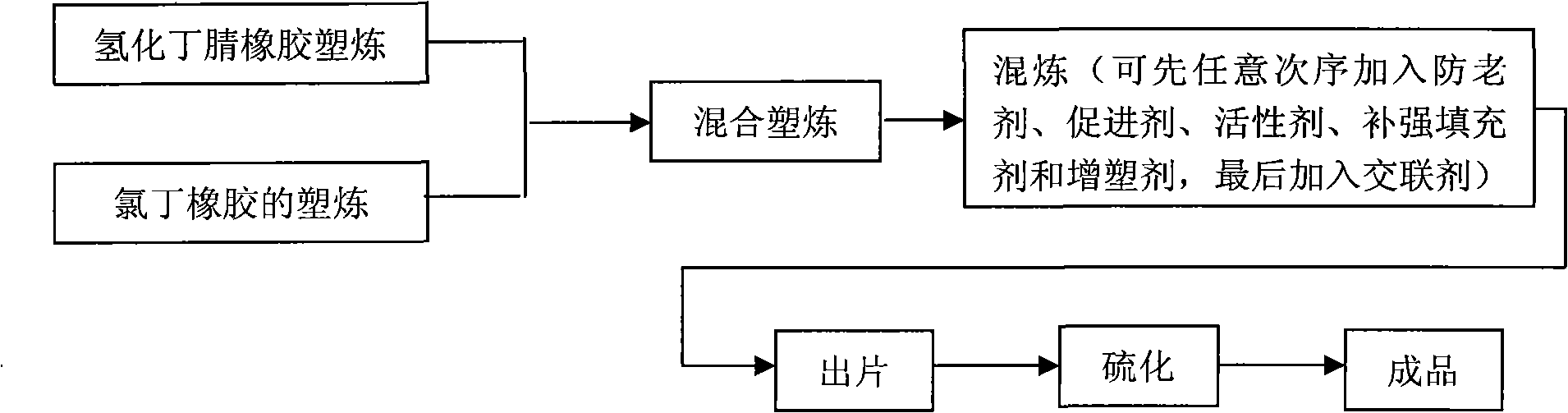

[0026] A kind of preparation method of hydrogenated nitrile butadiene rubber and neoprene blend vulcanized rubber of the present embodiment, comprises the following steps:

[0027] Step 1, carrying out mastication respectively to hydrogenated nitrile rubber and chloroprene rubber;

[0028] Step 2, mixing the hydrogenated nitrile butadiene rubber and neoprene after masticating together for mixing and masticating;

[0029] Step 3. Cover the blended rubber material after mixing and masticating for 2 minutes, then add anti-aging agent, accelerator and active agent in sequence. After eating the material, turn 3 / 4 of the left and right cutters for 3 times;

[0030] Step 4. Thinly pass the lower slice of the blended rubber material, add reinforcing fillers, after the flour is eaten, 3 / 4 of the left and right cutters are turned over for 4 times, and the lower slice is thinly beaten into triangular bags for 3 times;

[0031] Step 5. Add plasticizer, disperse it into the rubber, and th...

Embodiment 2

[0042] A kind of preparation method of hydrogenated nitrile butadiene rubber and neoprene blend vulcanized rubber of the present embodiment, comprises the following steps:

[0043] Step 1, carrying out mastication respectively to hydrogenated nitrile rubber and chloroprene rubber;

[0044] Step 2, mixing the hydrogenated nitrile butadiene rubber and neoprene after masticating together for mixing and masticating;

[0045] Step 3. Cover the blended rubber material after mixing and masticating for 2 minutes, then add anti-aging agent, accelerator and active agent in sequence. After eating the material, turn 3 / 4 of the left and right cutters for 3 times;

[0046] Step 4. Thinly pass the lower slice of the blended rubber material, add reinforcing fillers, after the flour is eaten, 3 / 4 of the left and right cutters are turned over for 4 times, and the lower slice is thinly beaten into triangular bags for 3 times;

[0047] Step 5. Add plasticizer, disperse it into the rubber, and th...

Embodiment 3

[0058] A kind of preparation method of hydrogenated nitrile butadiene rubber and neoprene blend vulcanized rubber of the present embodiment, comprises the following steps:

[0059] Step 1, carrying out mastication respectively to hydrogenated nitrile rubber and chloroprene rubber;

[0060] Step 2, mixing the hydrogenated nitrile butadiene rubber and neoprene after masticating together for mixing and masticating;

[0061] Step 3. Cover the blended rubber material after mixing and masticating for 2 minutes, then add anti-aging agent, accelerator and active agent in sequence. After eating the material, turn 3 / 4 of the left and right cutters for 3 times;

[0062] Step 4. Thinly pass the lower slice of the blended rubber material, add reinforcing fillers, after the flour is eaten, 3 / 4 of the left and right cutters are turned over for 4 times, and the lower slice is thinly beaten into triangular bags for 3 times;

[0063] Step 5. Add plasticizer, disperse it into the rubber, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com