Environment-friendly rubber plastic heat-insulating material and its preparation method

An insulating material and an environment-friendly technology, which is applied in the field of environment-friendly rubber-plastic insulating materials and their preparation, and can solve the problems of large chloride ion pitting and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention is further illustrated below with examples, but the present invention is not limited thereto.

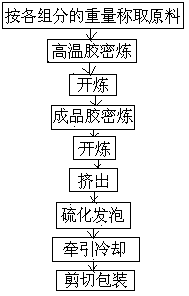

[0069] The preparation method of embodiment comprises the following steps:

[0070] (1) take the raw material by the weight of the components in the above-mentioned each embodiment and each component;

[0071] (2) High-temperature rubber mixing: the components weighed in parts by weight include nitrile rubber, aluminum hydroxide, polyethylene glycol, antimony trioxide, protective wax, oxidized paraffin wax, anti-aging agent (4020), DCP cross-linking agent, anti-aging agent (RD), antioxidant (AST-500), dioctyl ester (DOP), and epoxy soybean oil (ADDA) are put into the mixing room and mixed until high temperature discharge. The plastic is made of EVA material, and the density The refining temperature is about 160°C;

[0072] (3) Milling: Pour the output from step (2) into the mill to slice, the thickness of the cut film is 6.5mm, and the width of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com