The external wall system and construction method of cast-in-place prefabricated non-disassembly integrally assembled thermal insulation external formwork

An external formwork, dismantling-free technology, used in thermal insulation, walls, buildings, etc., can solve the problems of non-adhesion between the thermal insulation layer and concrete, variability of the thermal insulation layer, and hollowing at the bonding place, so as to shorten the construction period and improve the Build quality, improve thermal performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

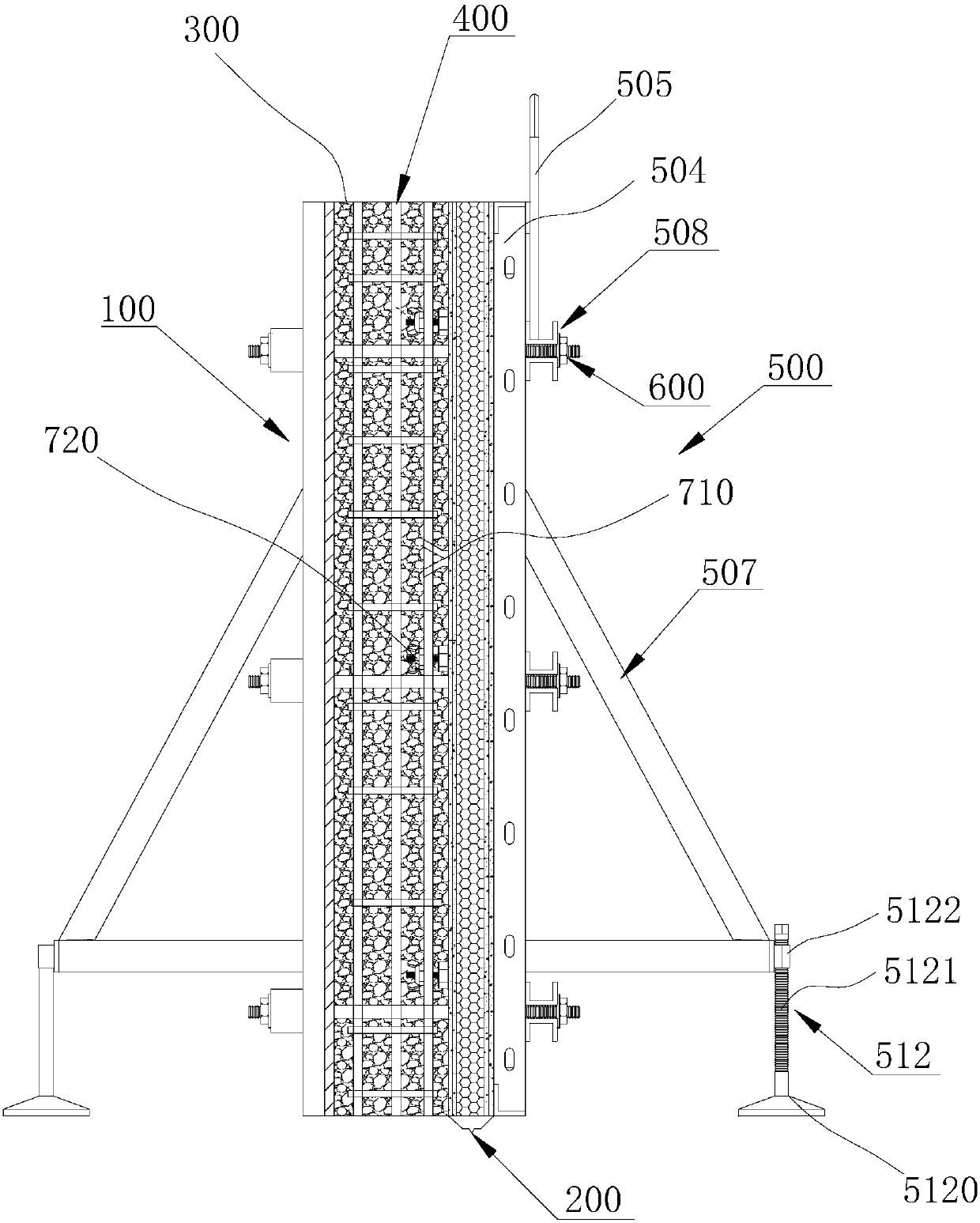

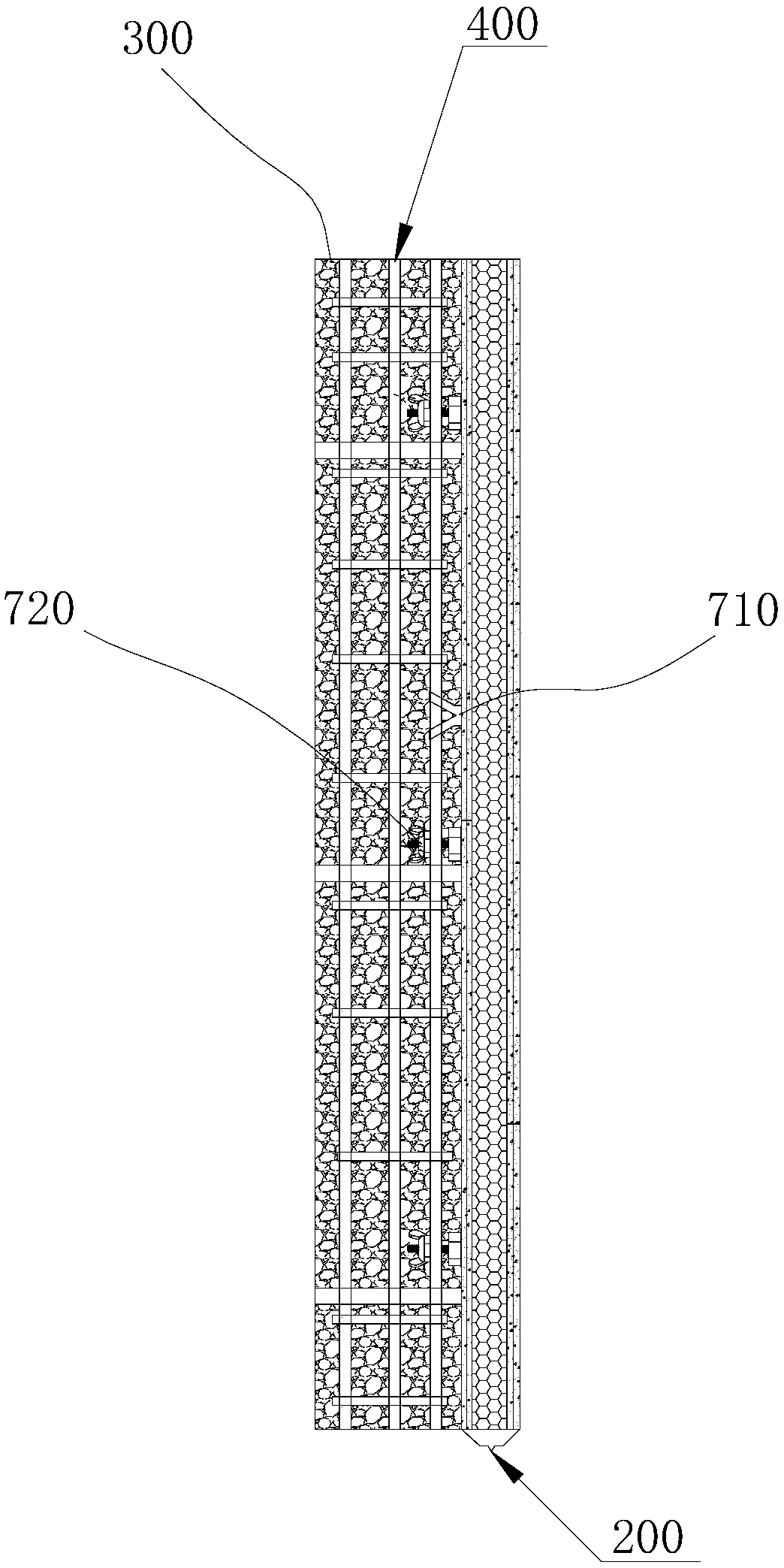

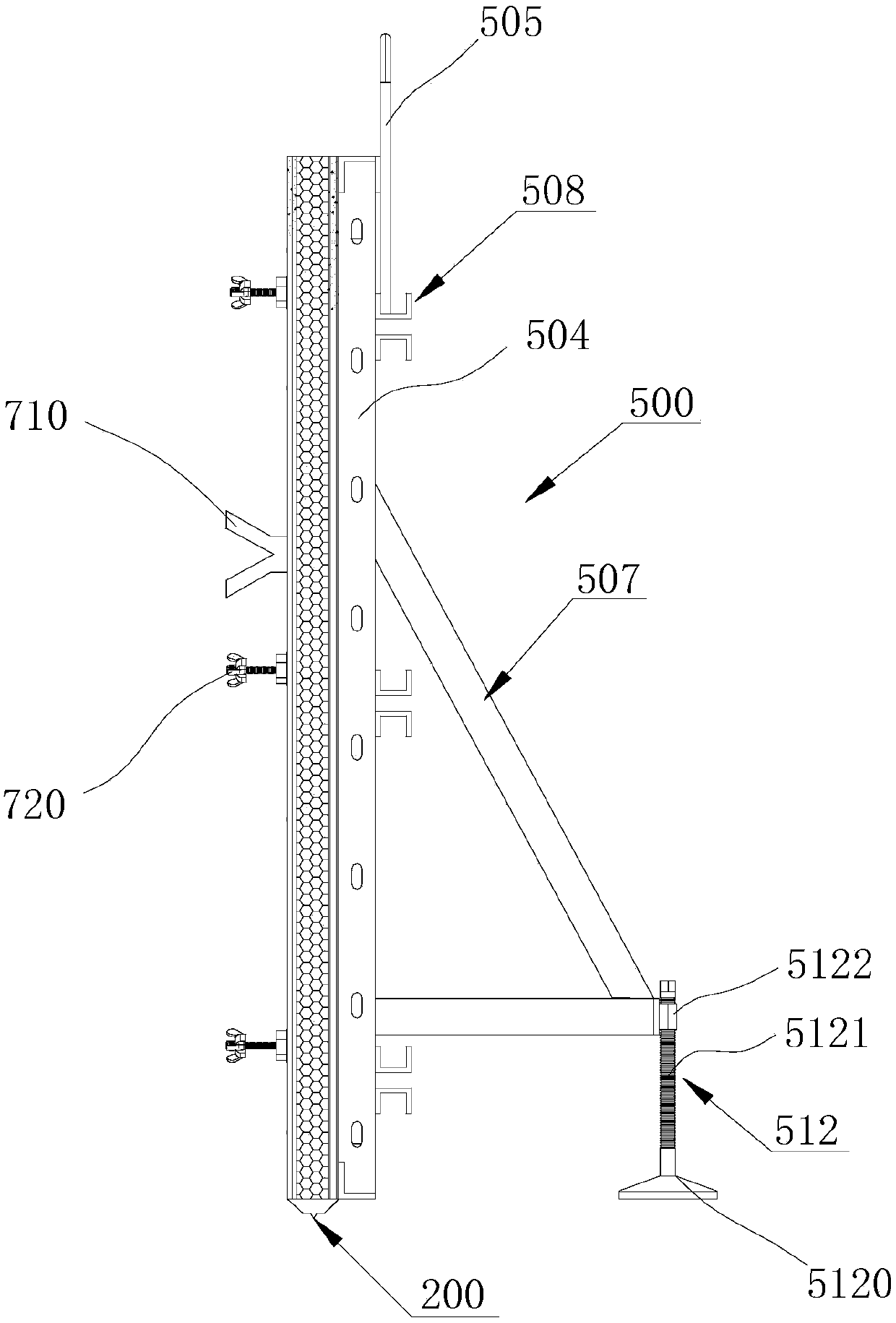

[0070] see Figure 1 to Figure 7 , a cast-in-place prefabricated exterior wall system with integrally assembled thermal insulation formwork without disassembly, comprising a prefabricated exterior wall composite thermal insulation formwork unit 210 and an inner formwork 100; the prefabricated exterior wall composite thermal insulation formwork monomers are spliced to form a prefabricated integrally assembled thermal insulation exterior formwork 200, the inner cavity of the cast-in-place shear wall is formed between the prefabricated integrally assembled thermal insulation outer formwork 200 and the inner formwork 100, and the wall reinforcement 400 is bound in the inner cavity; the inner side of the prefabricated integrally assembled thermal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com