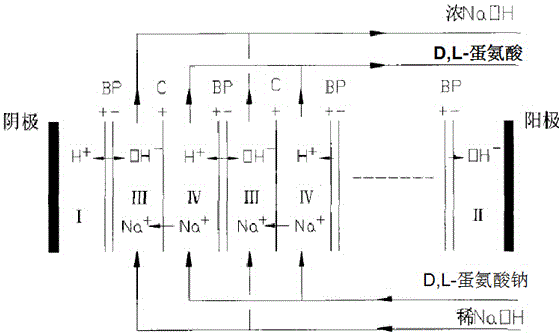

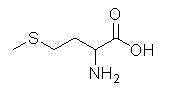

Environment-friendly clean production method of D,L-methionine

A clean production, methionine technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of thioethers, etc., can solve the problems of D, L-methionine product loss, high production cost, difficult salty wastewater, etc., to eliminate By-produced sulfate or hydrochloride, the effect of reducing treatment costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

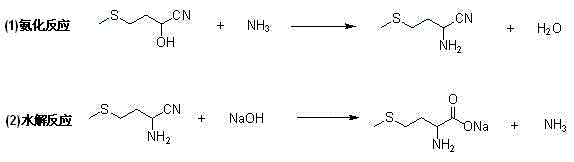

Method used

Image

Examples

Embodiment 1

[0032] 1) Preparation of 2-amino-4-methylthiobutyronitrile: At 85°C, introduce 625.5g of ammonia water with a mass fraction of 40% into a stainless steel high-pressure reactor equipped with a stirrer, thermometer, and pressure gauge , feed tube and heat source. Then, within 2 minutes, add 272.9 g of 96% 2-hydroxyl-4-methylthiobutyronitrile with a pump, heat up to 60 ° C while stirring, and the pressure reaches 1 MPa. At the same temperature, continue stirring for 15 minutes, and then The temperature was lowered to 15°C, and the pressure was reduced to normal pressure. HPLC analysis of the reaction mixture showed that 99.5% of the theoretical amount of 2-amino-4-methylthiobutyronitrile was formed.

[0033] 2) Preparation of D,L-methionine sodium: add 220 grams of 40% sodium hydroxide to the reactor, preheat to 65°C, and then slowly add the 2-amino-4-methylthiobutyronitrile obtained above dropwise The aqueous solution, after the dropwise addition, was stirred at 65°C for 40 min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com