Method for preparing porous molybdenum carbide nanofiber by adopting electrostatic spinning

An electrospinning and nanofiber technology, applied in the field of nanomaterials, can solve the problems of insufficient reaction, harsh conditions, low yield, etc., and achieves low cost of process conditions, simple and easy-to-control preparation conditions, good application and industrialization prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] A method for preparing porous molybdenum carbide nanofibers by electrospinning, comprising the steps of:

[0033] (1) 1.24 grams of ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 5ml distilled water to obtain ammonium molybdate solution (the molar concentration of molybdenum atom is about 1.4mol / L);

[0034] (2) 20 gram PVA powders are dissolved in 100 gram hot water, are made into the PVA solution of 20wt%;

[0035] (3) Ammonium molybdate solution is added to dissolve in 6.2 grams of PVA solution, and the mass ratio of PVA and ammonium molybdate in the mixed solution is about 1:1;

[0036] (4) Move the mixed solution to a syringe, install it on an electrospinning micropump, and connect the needle of the syringe to a high-voltage power supply;

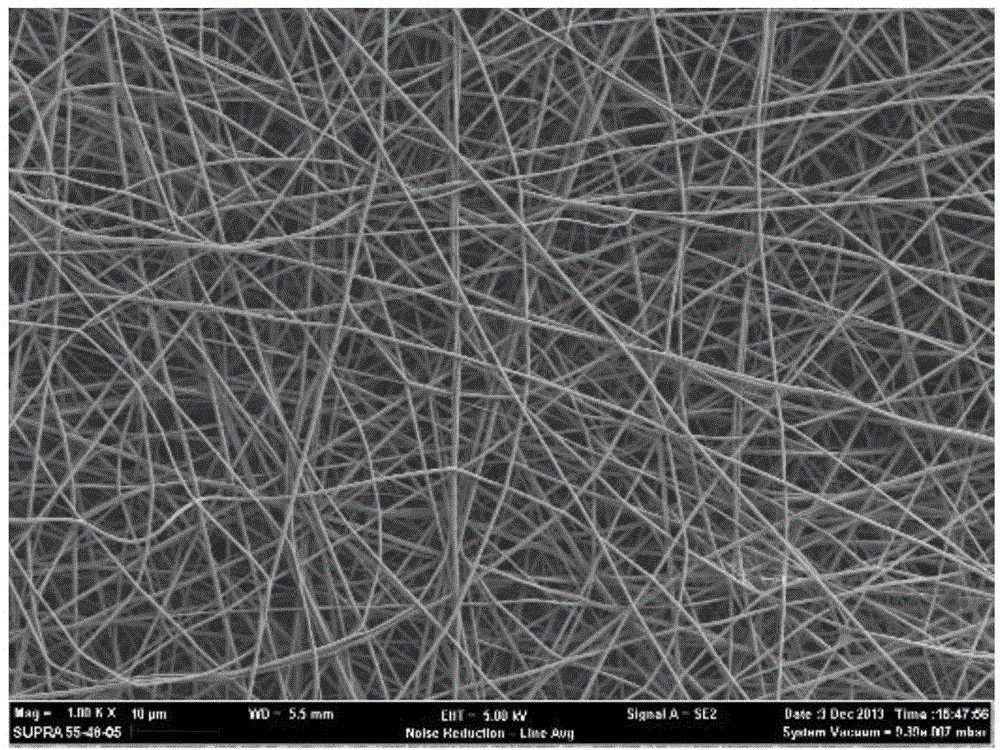

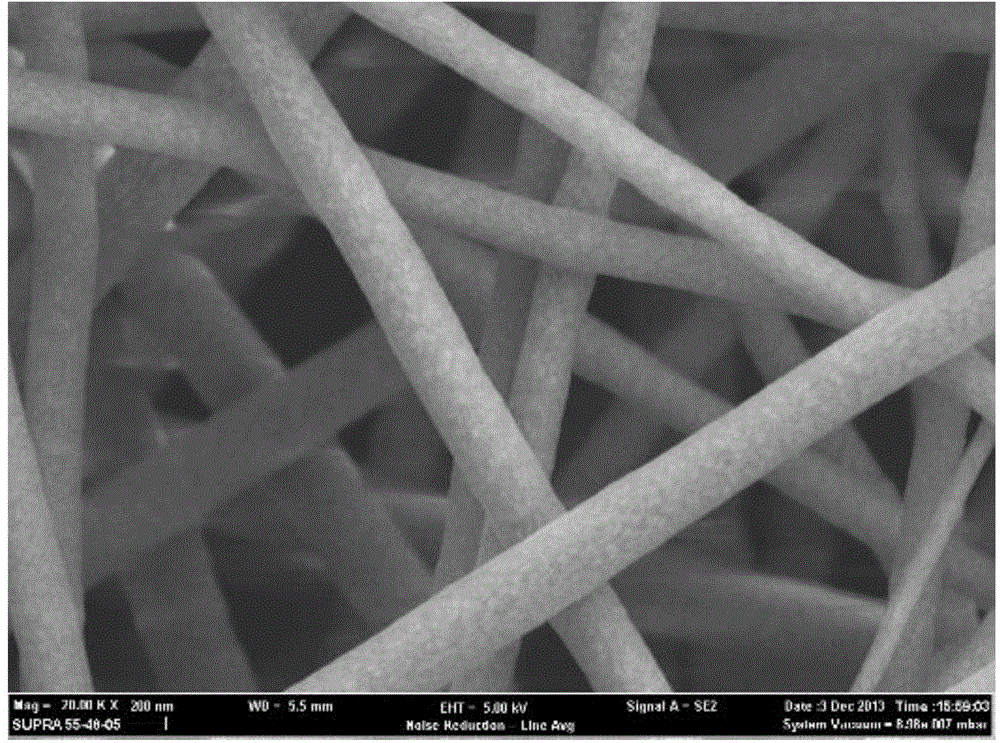

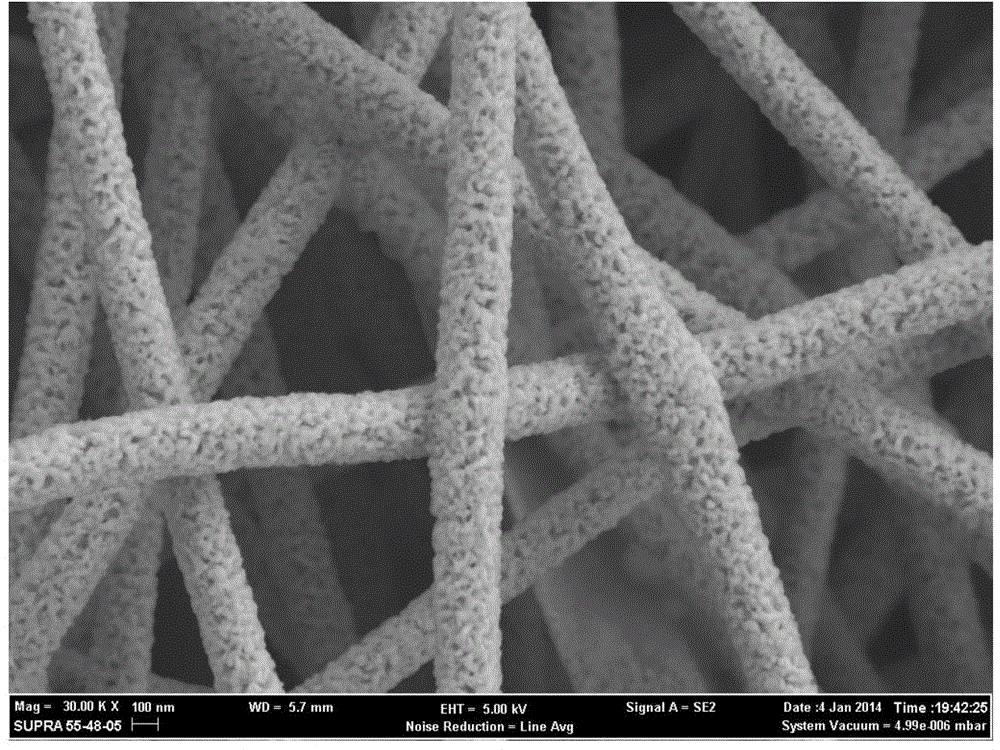

[0037] (5) Regulate micropump injection speed 0.1ml / h, set high voltage 15kV, continue spinning for 1 hour, obtain white electrospun fiber on negative electrode collection plate, as figure 1 and figure 2 ...

Embodiment 2

[0043] A method for preparing porous molybdenum carbide nanofibers by electrospinning, comprising the steps of:

[0044] (1) 1.86 grams of ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H2 O is dissolved in 5ml distilled water to obtain ammonium molybdate solution (the molar concentration of molybdenum atom is about 2.1mol / L);

[0045] (2) 20 gram PVA powders are dissolved in 100 gram hot water, are made into the PVA solution of 20wt%;

[0046] (3) Ammonium molybdate solution is added to dissolve in 6.2 grams of PVA solution, and the mass ratio of PVA and ammonium molybdate in the mixed solution is about 2:1;

[0047] (4) Move the mixed solution to a syringe, install it on an electrospinning micropump, and connect the needle of the syringe to a high-voltage power supply;

[0048] (5) Adjust the micropump injection speed to 0.1ml / h, set high voltage 15kV, continue spinning for 1 hour, and obtain white electrospun fibers on the negative electrode collecting plate;

[0049] (6) Pu...

Embodiment 3

[0051] A method for preparing porous molybdenum carbide nanofibers by electrospinning, comprising the steps of:

[0052] (1) 0.62 grams of ammonium molybdate (NH 4 ) 6 Mo 7 o 24 4H 2 O is dissolved in 5ml distilled water to obtain ammonium molybdate solution (the molar concentration of molybdenum atom is about 0.7mol / L);

[0053] (2) 20 gram PVA powders are dissolved in 100 gram hot water, are made into the PVA solution of 20wt%;

[0054] (3) Add the ammonium molybdate solution to 6.2 grams of PVA solution for dissolving, so that the mass ratio of PVA and ammonium molybdate in the mixed solution is about 1:2;

[0055] (4) Move the mixed solution to a syringe, install it on an electrospinning micropump, and connect the needle of the syringe to a high-voltage power supply;

[0056] (5) Adjust the micropump injection speed to 0.1ml / h, set high voltage 15kV, continue spinning for 1 hour, and obtain white electrospun fibers on the negative electrode collecting plate;

[0057...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com