Electret nano fiber filter material for HVAC (heating, ventilating, and air conditioning) and preparation method thereof

A technology of nanofibers and filter materials, which is applied in the field of electrospun nanofiber electret filter materials for HVAC and its preparation, which can solve the problems of easy failure and service life, and limit the effect of HVAC systems on improving air quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A kind of preparation method of electret nanofiber filter material for HVAC, its concrete steps are as follows:

[0054] (1) Prepare a liquid mixture in which the polymer is dissolved: add polyvinylidene fluoride to N,N-dimethylformamide, and continuously stir for 11 hours with a magnetic stirring device;

[0055] (2) Electrospinning is carried out after being heated to 50 ℃ with the liquid mixture that dissolves the polymer that mass concentration is 22%, carries out rapid cooling and solidification to the liquid mixture that dissolves the polymer in the spinneret hole during the electrospinning process, Among them, rapid cooling and solidification means that the liquid mixture dissolved in polymer is cooled to -40°C within 0.3ms at the outlet 3cm of the spinneret hole. The process parameters of electrospinning are: voltage 50KV, receiving distance 20cm, infusion speed 0.1 mL / h, temperature is 20°C, humidity is 55%;

[0056] (3) The fiber obtained by electrospinning i...

Embodiment 2~24

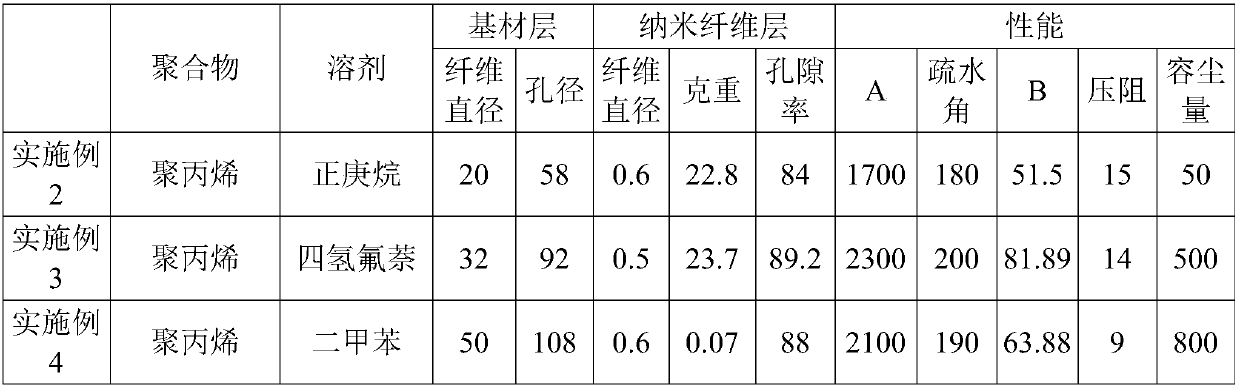

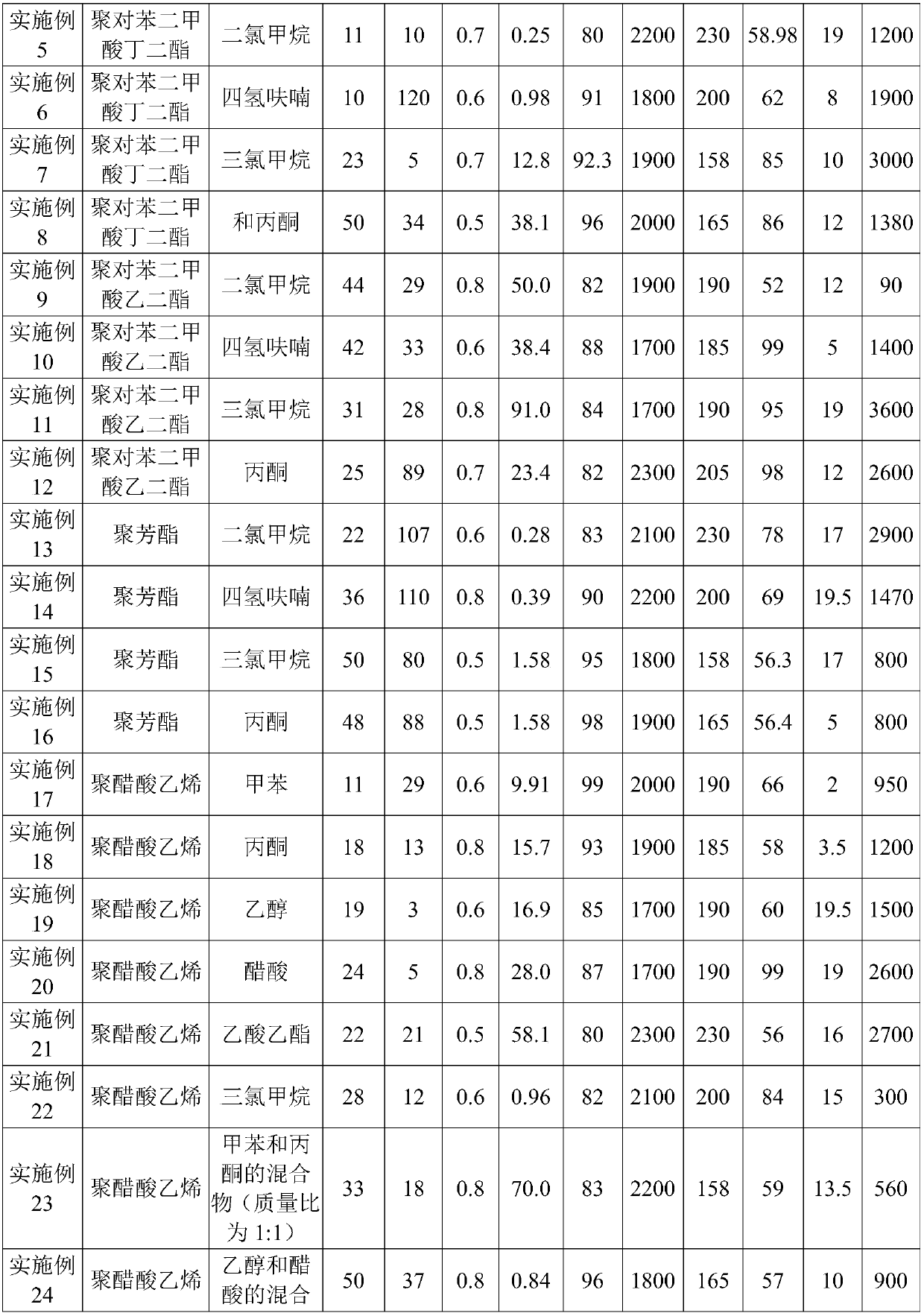

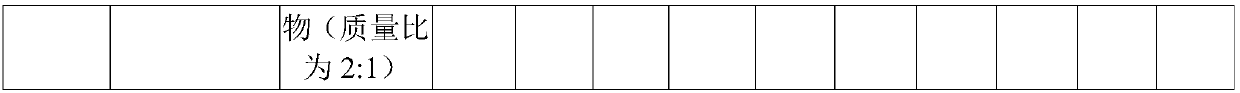

[0061] A kind of preparation method of electret nanofiber filter material for HVAC, its specific steps are consistent with embodiment 1, difference is the kind of polymer and solvent selected when step (1) prepares the liquid mixture that dissolves polymer and final The performance of the prepared product is shown in the table below. In the table, A represents the surface electrostatic potential, B represents the filtration efficiency for particles of 0.006-1 μm, the unit of fiber diameter is μm, and the unit of pore size is μm; The unit of fiber diameter is μm, and the unit of nanofiber weight is g / m 2 , the unit of porosity is %; the unit of A is V, the unit of hydrophobic angle is (°), the unit of B is %, the unit of piezoresistance is Pa, and the unit of dust holding capacity is g / m 2 :

[0062]

[0063]

[0064]

Embodiment 25

[0066] A kind of preparation method of electret nanofiber filter material for HVAC, its concrete steps are as follows:

[0067] (1) Prepare a liquid mixture in which the polymer is dissolved: add polyvinylidene fluoride to N-methylpyrrolidone, and continuously stir for 18 hours with a magnetic stirring device;

[0068](2) Electrospinning is carried out after heating the polymer-dissolved liquid mixture with a mass concentration of 36% to 85° C. During the electrospinning process, the polymer-dissolved liquid mixture in the spinneret hole is rapidly cooled and solidified, Among them, rapid cooling and solidification means that the liquid mixture dissolved in polymer is cooled to -20°C within 0.1ms at the outlet 4cm of the spinneret hole. The process parameters of electrospinning are: voltage 20KV, receiving distance 10cm, infusion speed 5.2 mL / h, temperature is 15°C, humidity is 60%;

[0069] (3) The fiber obtained by electrospinning is instantly cooled to below 0°C after bein...

PUM

| Property | Measurement | Unit |

|---|---|---|

| stiffness | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com