Composite fiber and its preparation method

A composite fiber and short fiber technology, applied in the direction of fiber processing, one-component polyamide rayon, one-component polyester rayon, etc., can solve the problems of not being applicable for a long time, achieve cost reduction, and promote wide application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

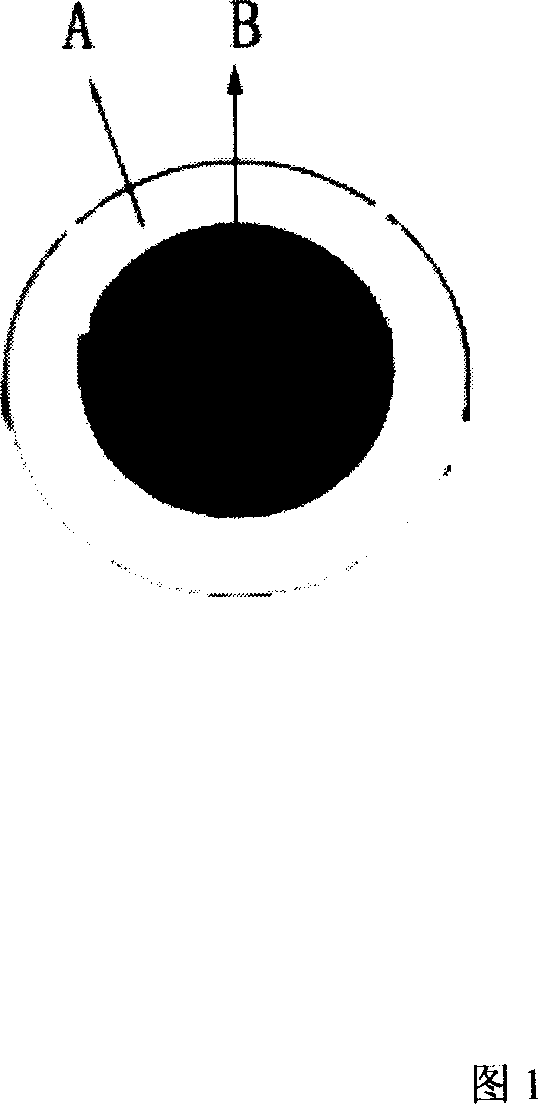

Image

Examples

Embodiment 1

[0024] Drying of raw materials: PPS slices are screened and then sent to a vacuum drum for airtight vacuuming and heating. The temperature was raised to 150° C. for 8 hours and kept for 10 hours. After cooling, the material is delivered to the A# spinning material storage barrel. PET slices, intrinsic viscosity 0.68, heating time in the vacuum drum for 6 hours to 130°C, keeping warm at this temperature for 6 hours, and transporting to B# spinning material storage barrel after cooling. A# spinning screw temperature: 85°C in cooling zone, 295°C in feeding zone, 315°C in melting zone, 325°C in metering compression zone, and 315°C in elbow flange zone.

[0025] B# spinning screw temperature: cooling zone 70°C, feeding zone 275°C, melting zone 290°C, metering compression zone 300°C, elbow flange zone 285°C, composite spinning box 310°C, ring blowing plate distance 25cm, Wind speed 0.42m / min, wind temperature 28°C, unit suction air volume 70mm / H 2 O, spinning speed 750m / min. The...

Embodiment 2

[0027] Raw material dried PPS slices are the same as in Example 1, PET intrinsic viscosity is 0.82dl / g, the temperature is raised in the vacuum drum for 8 hours to 150°C, kept for 6 hours, cooled and transported to B# spinning storage barrel. The temperature of A# spinning screw is 85°C in the cooling zone; 298°C in the feed zone; 320°C in the melting zone; 330°C in the metering compression zone; 320°C in the elbow flange zone. B# spinning screw temperature, cooling zone 75°C; feeding zone 280°C; melting zone 295°C; metering compression zone 305°C; elbow flange zone 290°C. The temperature of the composite spinning box is 315°C, the distance between the ring blowing plates is 28cm; the wind speed is 0.45m / min; the wind temperature is 26°C. Unit suction air volume 65mm / H 2 O, spinning speed 700m / min. Total post-stretching ratio: 4.5 times; primary stretching ratio: 3.55 times, stretching temperature (oil bath): 78°C; secondary stretching ratio: stretching temperature (heating ...

Embodiment 3

[0029] The raw materials are dried, and the PPS chips are the same as in Example 1, except that the PET chips are replaced with PA chips with a molecular weight of 15800, and the temperature is raised in a vacuum drum for 7 hours to 130°C, kept at this temperature for 6 hours, and then transported to B# after cooling Spinning storage barrels. A# spinning screw temperature, cooling zone 75°C; feed zone 295°C; melting zone 315°C; metering compression zone 320°C; elbow flange zone 315°C. B# spinning screw temperature, cooling zone 70°C; feeding zone 270°C; melting zone 285°C; metering compression zone 295°C; elbow flange zone 280°C. The temperature of the composite spinning box is 310°C, the distance between the ring blowing plates is 30cm; the wind speed is 0.35m / min; the wind temperature is 22°C. Unit suction air volume 65mm / H 2 O, spinning speed 680m / min. The total post-stretching ratio is 5.01 times; the primary stretching ratio is 3.6 times, and the stretching temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com