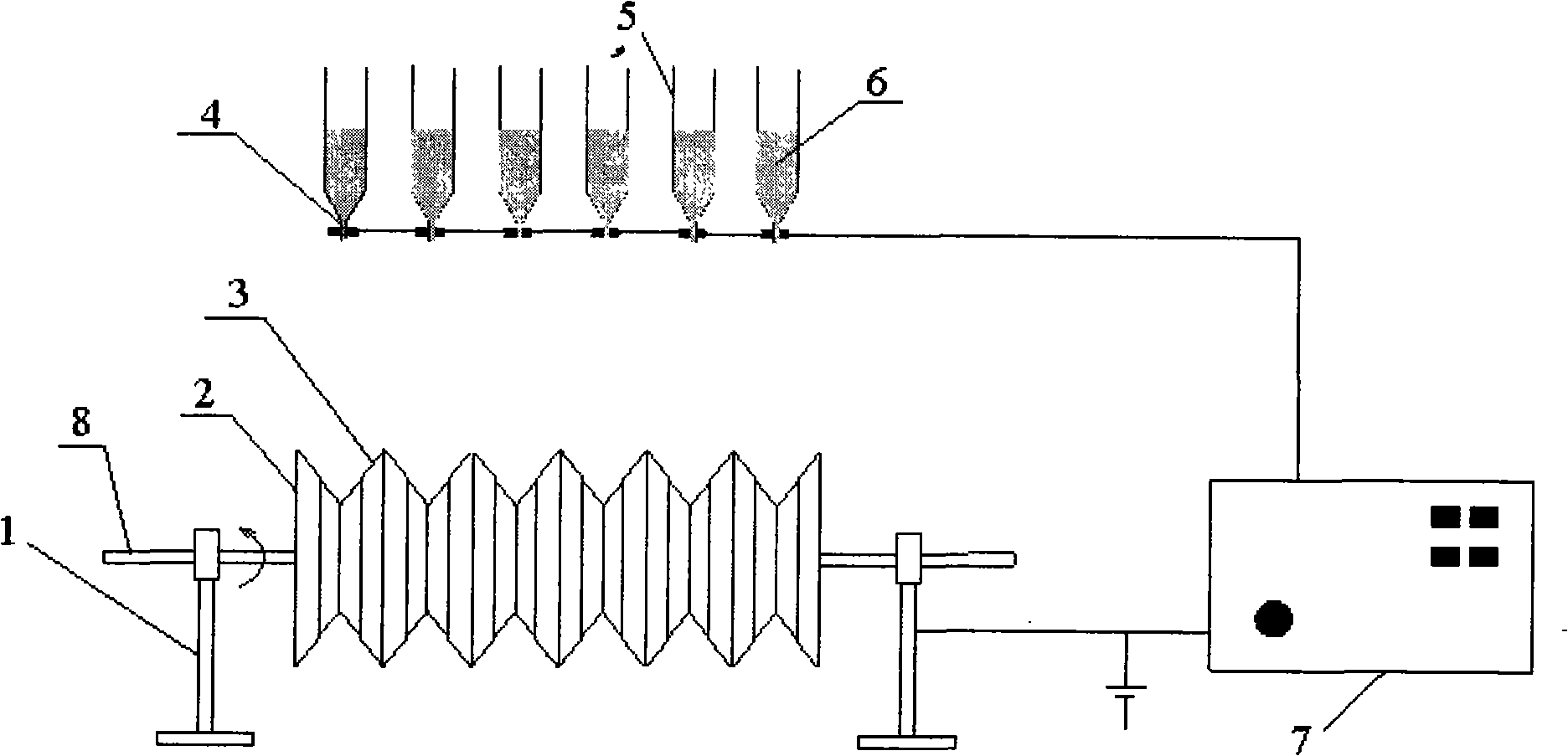

Multi-needle V-shaped groove drum electrostatic spinning system and preparation of nano-fiber tuft

A nanofiber, V-groove technology, applied in the field of electrospinning system, multi-needle V-groove drum electrospinning system, can solve the problem of poor orientation, low yield of nanofibers, and inability to bundle nanofibers well. problems, to achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Polyacrylonitrile (PAN) (Mw=70,000g / mol) was dissolved in the solvent N,N-dimethylformamide (DMF) to prepare a uniform and stable spinning solution 6 with a concentration of 10wt%. Inject the spinning solution into the syringes 5 of the electrospinning system respectively. Metal needles 4 are installed at the outlets of the syringes 5. At room temperature and in an environment with a relative humidity of 40%, turn on the DC high voltage generator of the electrospinning system. 1 and drum 2, an electrospinning jet is formed between the metal needle 4 and drum 2 for electrospinning, the control voltage is 15kV, the winding speed is 200r / min, the receiving distance is 100mm and the solution flow rate is 0.1mL / h. The electrospinning jet is continuously deposited on the bottom of the V-shaped groove of the drum 2 to form nanofiber bundles with aligned fibers and an arrangement angle of 60°-80°.

Embodiment 2

[0042] Polyvinyl alcohol (PVA) 1788 type powder was dissolved in 70°C distilled water to prepare spinning solution 6 with a concentration of 16 wt%. The spinning solution 6 is respectively injected into each syringe 5 of the electrospinning nanofiber bundle system, and a metal needle 4 is installed at the outlet of the syringe 5, and the DC high voltage of the electrospinning system is turned on at room temperature and in an environment with a relative humidity of 70%. The generator 1 and the drum 2 form an electrospinning jet between the metal needle 4 and the drum 2 for electrospinning, the control voltage is 40kV, the winding speed is 500r / min, the receiving distance is 200mm and the solution flow rate is 0.5mL / min h, The electrospinning jet is continuously deposited on the bottom of the V-shaped groove of the drum 2 to form nanofiber bundles with aligned fibers and an arrangement angle of 70°-90°.

Embodiment 3

[0044] Polyethylene oxide (PEO) (Mw=3×10 5 ) was dissolved in distilled water at 60° C. to prepare spinning solution 6 with a concentration of 13 wt%. The spinning solution 6 is respectively injected into each syringe 5 of the electrospinning nanofiber bundle system, and a metal needle 4 is installed at the outlet of the syringe 5, and the DC high voltage of the electrospinning system is turned on at room temperature and in an environment with a relative humidity of 55%. The generator 1 and the drum 2 form an electrospinning jet between the metal needle 4 and the drum 2 for electrospinning, the control voltage is 28kV, the winding speed is 350r / min, the receiving distance is 150mm and the solution flow rate is 0.3mL / min h, The electrospinning jet is continuously deposited on the bottom of the V-shaped groove of the drum 2 to form nanofiber bundles with aligned fibers and an arrangement angle of 65°-90°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com