A magnetic spinning device and a method for preparing micro-nano fibers using the device

A technology of micro-nano fiber and magnetic spinning, which is applied in the direction of spinning solution preparation, fiber treatment, textiles and papermaking, etc. It can solve the problems of increasing industrial production costs, low spinning output, and hidden dangers of operators, so as to overcome production costs High quality, high degree of fiber order, and easy operation of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

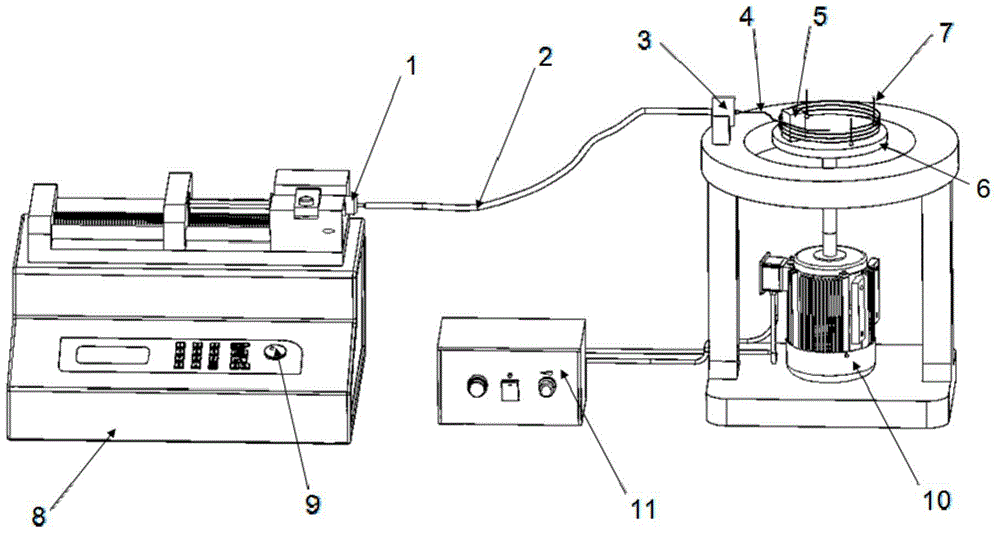

[0026] Such as figure 1Shown, a kind of magnetic spinning device comprises the feeding device that can control feeding rate, spinning nozzle 4, nozzle driving mechanism and spinning receiving device, and described spinning receiving device comprises the collecting disc 6 that is arranged horizontally, and The center of the bottom circle of the collecting disc 6 is docked with the output shaft of the DC brushless motor 10 for linkage, and the DC brushless motor 10 is electrically connected to the power supply and the motor controller 11 for controlling the motor speed. The central axis is a symmetrical axis and a plurality of vertical pillars are symmetrically arranged. The vertical pillars are at least 3, and one of the vertical pillars is a permanent magnet 5, and the rest are metal fine needles 7. The spinning nozzle 4 is arranged horizontally. The injection port of the spinning nozzle 4 points to the permanent magnet 5 of the spinning receiving device. The spinning nozzle 4...

Embodiment 2

[0029] The method for preparing micro-nano fibers using the magnetic spinning device of embodiment 1 may further comprise the steps:

[0030] (1) Preparation of ferrofluid spinning solution: select sodium dodecylbenzene sulfonate as surfactant, and γ-Fe with a diameter of 20 nanometers 2 o 3 Disperse the magnetic nanoparticles into chloroform, add surfactants with the same quality as the magnetic nanoparticles, and prepare γ-Fe 2 o 3 Magnetic nanoparticles mass fraction is 11.5% ferrofluid solution; select water and dehydrated alcohol (volume ratio 70 / 30) as solvent, preparation mass fraction is 10% polyoxyethylene (molecular weight is 400000) solution, water bath is heated to Stir at 60°C for 2 hours to obtain a uniform polymer solution; mix the ferrofluid solution and the polymer solution at a ratio of 1:1 to make a ferrofluid spinning solution.

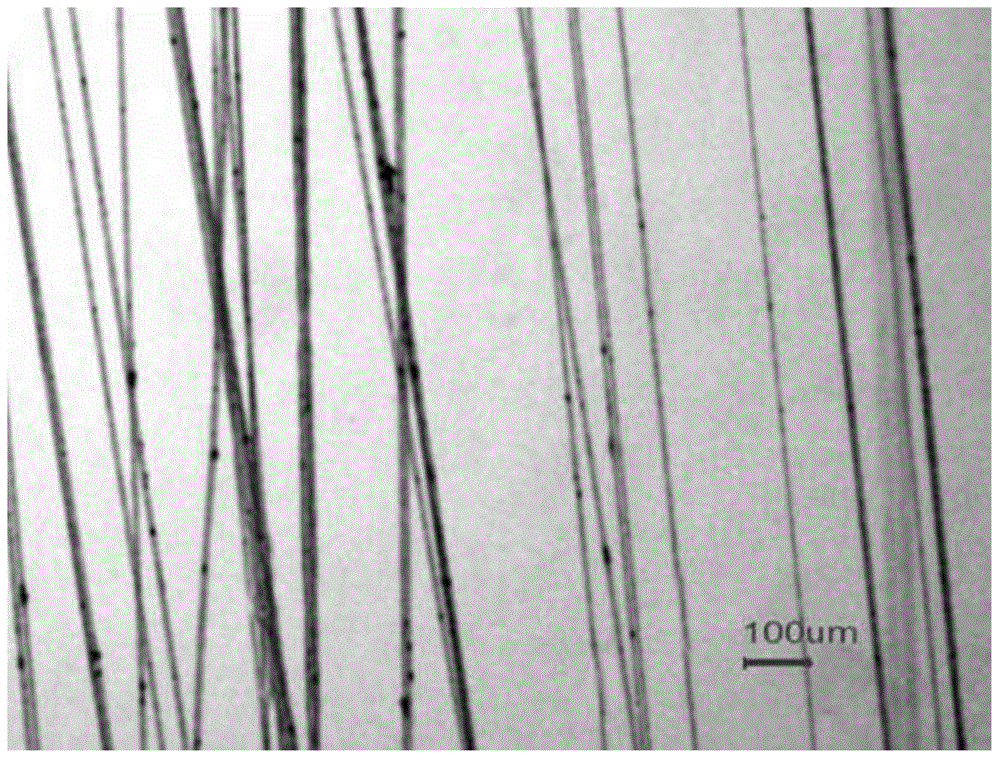

[0031] (2) Preparation of micro-nanofibers: Add the magnetic fluid spinning solution prepared in step (1) into the syringe nee...

Embodiment 3

[0033] The method for preparing micro-nano fibers using the magnetic spinning device of embodiment 1 may further comprise the steps:

[0034] (1) Preparation of ferrofluid spinning solution: select sodium dodecylbenzene sulfonate as surfactant, and γ-Fe with a diameter of 20 nanometers 2 o 3 Disperse the magnetic nanoparticles into chloroform, add surfactants with the same quality as the magnetic nanoparticles, and prepare γ-Fe 2 o 3 Magnetic nanoparticle mass fraction is 11.5% ferrofluid solution; Select chloroform as solvent, prepare the polyvinylidene fluoride (molecular weight 270000) solution that mass fraction is 25%, water bath is heated to 60 ℃, stirs 2 hours, obtains uniform high Molecular solution; mix ferrofluid solution and polymer solution at a ratio of 1:1 to make ferrofluid spinning solution.

[0035] (2) Preparation of micro-nanofibers: Add the magnetic fluid spinning solution prepared in step (1) into the syringe needle 1, turn on the micro-injection pump s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com