A kind of spinning method of aramid fiber

A fiber and aramid fiber technology, applied in the field of chemical fibers, can solve the problems of high-performance aramid III that cannot be used in bulletproof fields, low density of single-strand yarns, low production efficiency, etc., to reduce equipment investment and increase the number of spinneret holes , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A spinning method of aramid fiber III, said method comprising the steps of:

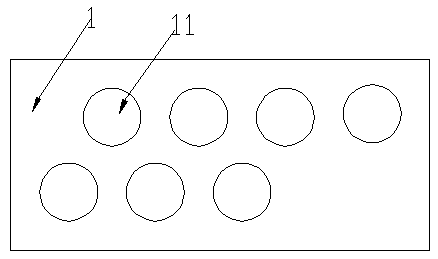

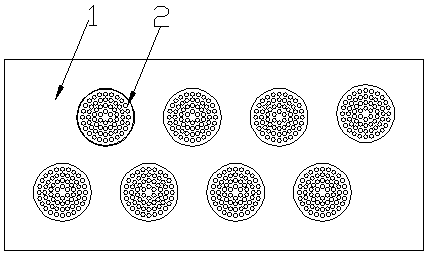

[0041] A Spinning: the spinning solution enters the spinneret, and extrudes a thin stream of spinning solution through the spinneret;

[0042] B. Primary extraction and coagulation: the fine flow of the spinning solution extruded in step A enters the primary extraction solution for extraction to form colloidal fibers; The organic solvent is extracted from the solvent until the solvent diffusion equilibrium;

[0043] C. Plasticizing and stretching: the colloidal fiber obtained in step B enters the plasticizing and stretching device for stretching and orientation; D, secondary extraction and solidification: the fiber stretched in step C enters the secondary extraction solution for secondary extraction Extract and solidify to form nascent fibers;

[0044] E, washing: the nascent fiber formed in step D enters the washing machine for washing;

[0045] F, heat treatment: after the fibers washed i...

Embodiment 2

[0048] This example is further improved on the basis of the example. This example provides a better composition of the extract, wherein the primary extract is a mixed solution of 1,4-dioxane and water, wherein 1,4 - The mass fraction of dioxane is 55%, and the temperature of the extract is 30°C.

[0049] The secondary extraction solution is a mixed solution of 1,4-dioxane and water, in which the mass fraction of 1,4-dioxane is 30%, and the temperature of the extraction solution is 28°C; The stretching ratio is 3.5 times.

Embodiment 3

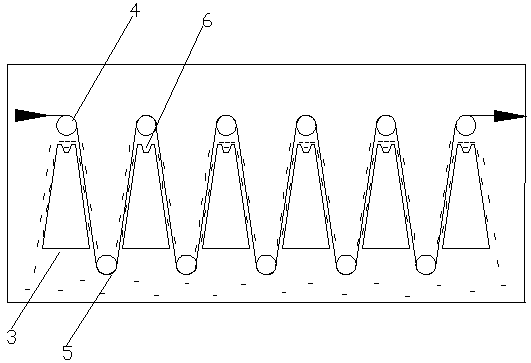

[0051] This embodiment is further improved on the basis of Embodiment 1, mainly to provide a new type of washing machine structure and washing method: the washing machine includes several trapezoidal washing walls 3 arranged in sequence, and a trapezoidal washing wall 3 above the trapezoidal washing wall A row of upper washing guide rollers 4 and a row of lower washing guide rollers 5 arranged below the trapezoidal washing wall 3, each upper end of the trapezoidal washing wall 3 is provided with an overflow tank 6, and the as-spun fibers obtained after step E are processed in The guiding function of the upper washing guide roller 4 and the lower washing guide roller 5 is parallel to the slope of the trapezoidal washing wall 3 and close to the slope of the trapezoidal washing wall 3, the washing water in the overflow tank 6 overflows and flows down along the slope of the trapezoidal washing wall 3 , to wash the as-spun fibers close to the trapezoidal washing wall 3. For washing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com