A method of preparation of a tungsten nano -nanofiber photogenic materials

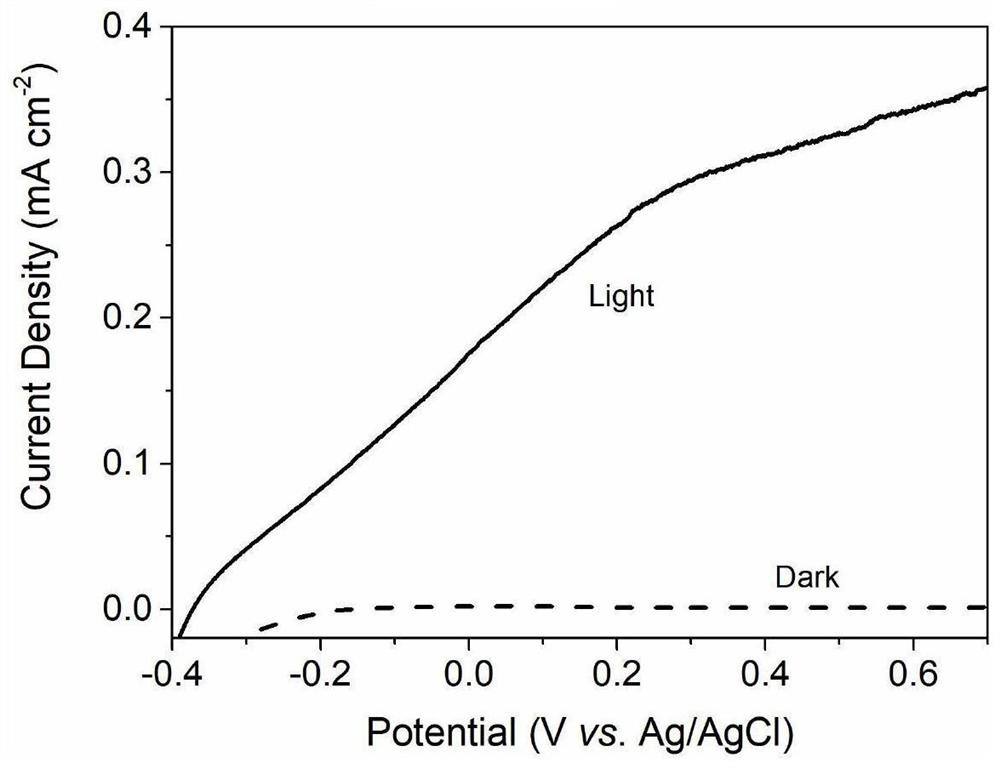

A nanofiber, photoanode technology, applied in the directions of nanotechnology, nanotechnology, fiber chemical characteristics, etc., can solve the problem of batch production of photoelectrode films, immature low-cost preparation methods, difficult FTO conductive glass surface, and hydrothermal reaction time. Long and other problems, to achieve the effect of low spinning cost, excellent photocurrent, and reduced distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0024] The present invention provides a SnWO 4 The preparation method of nanofiber photoanode material comprises the following steps:

[0025] Mixing the inorganic tin source, the inorganic tungsten source, the organic polymer and the organic solvent to obtain a spinning solution;

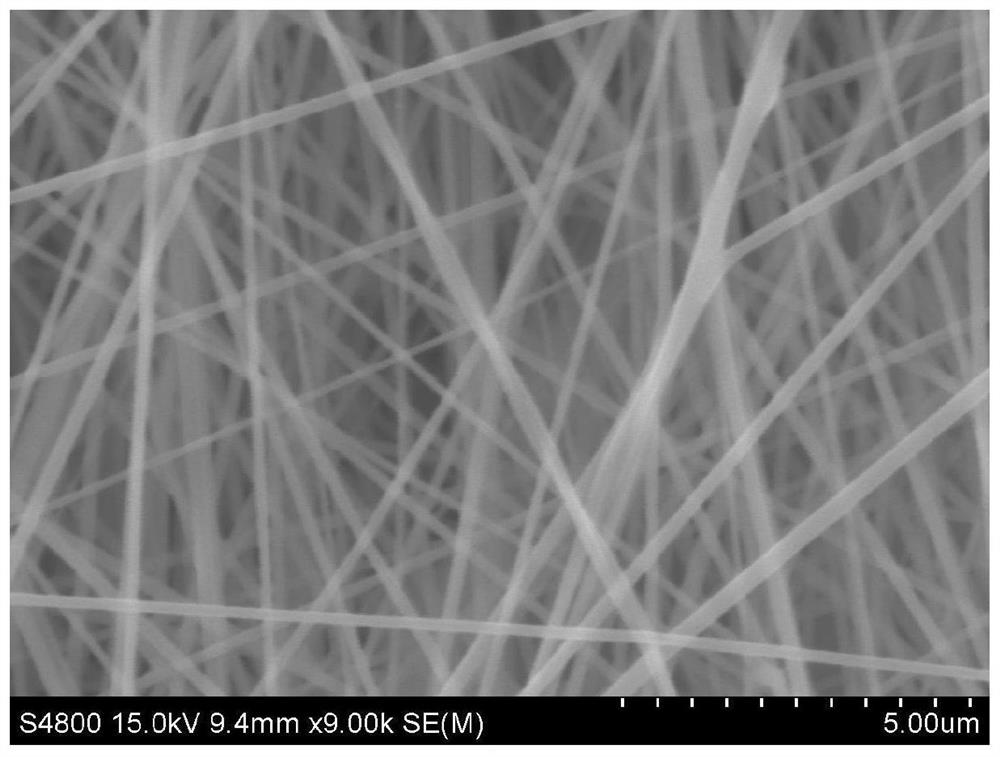

[0026] By means of electrospinning, three-dimensional nanofibers are prepared on the surface of FTO conductive glass by using the spinning solution;

[0027] calcining the three-dimensional nanofibers to obtain the SnWO 4 Nanofiber photoanode material.

[0028] In the present invention, unless otherwise specified, all raw material components are commercially available products well known to those skilled in the art.

[0029] In the invention, the inorganic tin source, the inorganic tungsten source, the organic macromolecular polymer and the organic solvent are mixed to obtain the spinning solution.

[0030] In the present invention, the inorganic tin source is preferably tin chloride or tin nit...

Embodiment 1

[0049] Mix 0.52 g of tin chloride, 0.79 g of tungsten chloride and 10 mL of ethanol (7.89 g), stir until all dissolved, add 0.8 g of polyvinylpyrrolidone, and stir for 12 h to obtain a spinning solution;

[0050] Under the condition of ultrasonic, the FTO conductive glass was washed with water, ethanol and acetone in turn, and then washed with high-purity N 2 Blow dry, spare;

[0051] Use a pipette to transfer 200 μL of 5% polyvinyl alcohol aqueous solution for spin coating onto the surface of the cleaned FTO conductive glass with a size of 2 × 2 cm, and then fix the FTO conductive glass on the drum of the electrospinning device. . At the same time, the spinning solution was poured into the syringe, and the electrospinning process parameters were set: the spinning voltage was 20 kV, the rotation speed of the drum was 150 r / min, and the advancing speed was 1 mm / h, and electrospinning was performed to obtain three-dimensional nanofibers;

[0052] The three-dimensional nanofibe...

Embodiment 2

[0055] Mix 0.52 g of tin chloride, 0.79 g of tungsten chloride and 10 mL of ethanol (7.89 g), stir until all dissolved, add 1 g of polyvinylpyrrolidone, and stir for 12 h to obtain a spinning solution;

[0056] Under the condition of ultrasonic, the FTO conductive glass was washed with water, ethanol and acetone in turn, and then washed with high-purity N 2 Blow dry, spare;

[0057] Pipette 300 μL of 10% polyvinyl alcohol aqueous solution and spin-coat it onto the surface of the cleaned FTO conductive glass with a size of 2 × 2 cm, and then fix the FTO conductive glass on the drum of the electrospinning device. . At the same time, pour the spinning solution into the syringe, and set the electrospinning process parameters: the spinning voltage is 15kV, the drum speed is 100r / min, and the advancing speed is 2mm / h, and electrospinning is performed to obtain three-dimensional nanofibers;

[0058] The three-dimensional nanofibers were taken out, kept in a muffle furnace at 100 °C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com