Dry spinning preparation method of polyarylether fibers with phthalazone structure

A phthalazinone and dry spinning technology, which is applied in the direction of spinning solution preparation, single-component polyether artificial filament, dry spinning, etc., to achieve dielectric properties, radiation resistance, high heat resistance, and equipment less demanding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

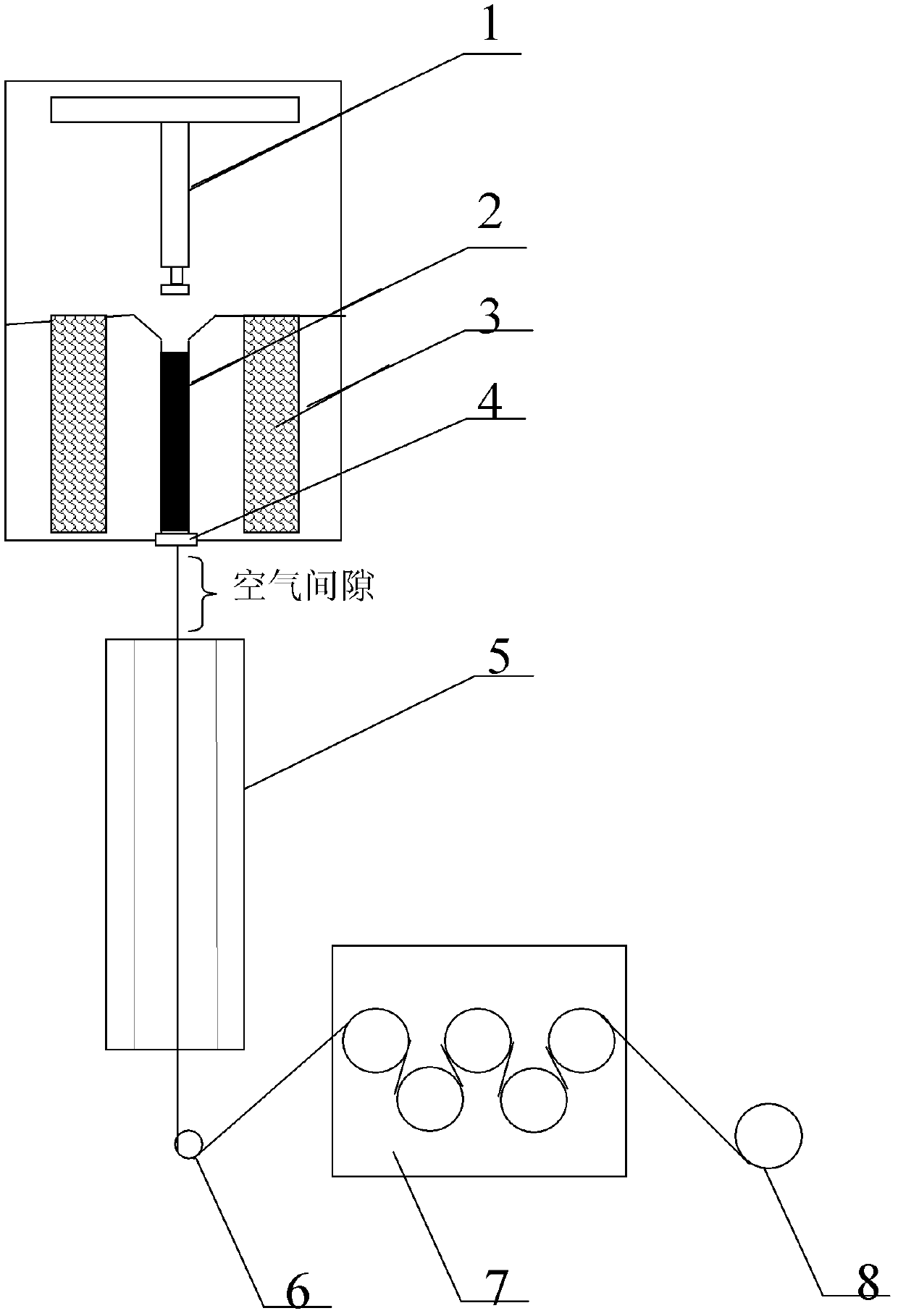

Method used

Image

Examples

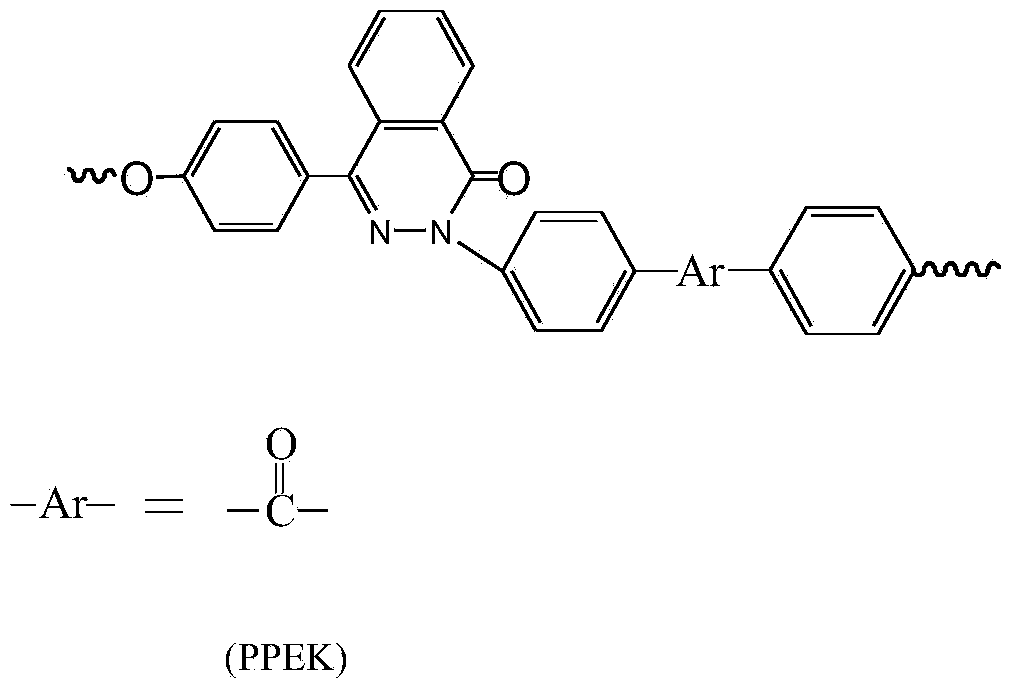

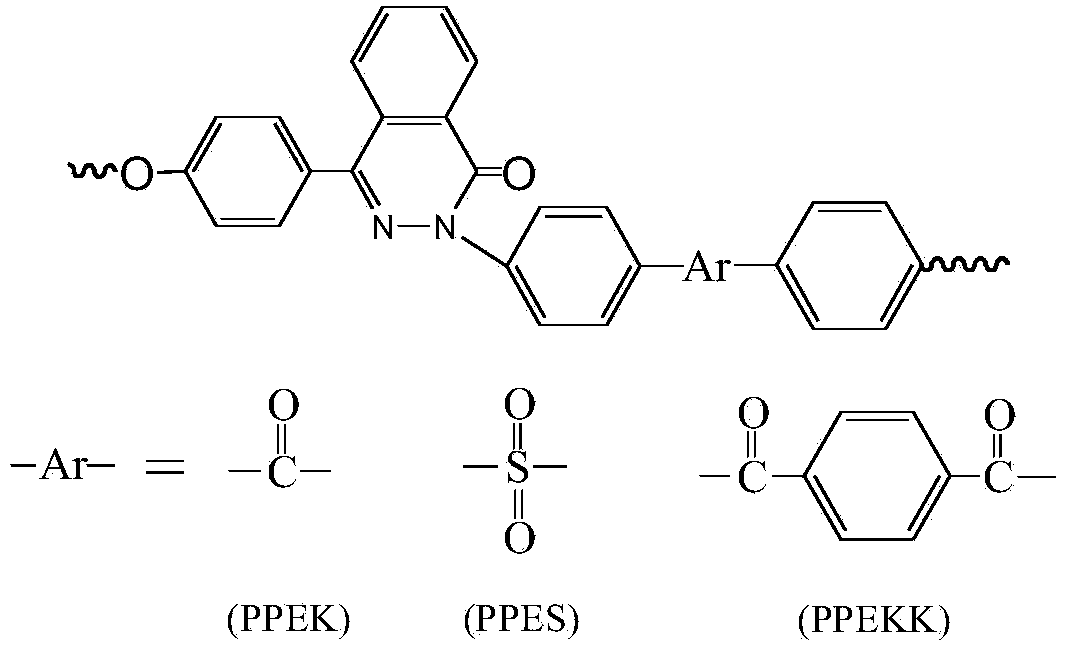

Embodiment 1

[0014] Dry the spinning-grade polyaryletherketone (PPEK) resin powder containing phthalazinone structure at 140°C for 48 hours in a blast drying oven, accurately weigh 53.85g of the dried PPEK powder and add it to 100g of NMP Put the split flask in an oil bath, stir and dissolve PPEK at 130°C, the stirring speed is 11r / min, the dissolution time is 3h, and prepare a PPEK spinning stock solution with a mass concentration of 35%. Put the prepared spinning stock solution in a vacuum oven for 8 hours at 80°C and a vacuum of 0.1MPa for defoaming, then transfer to the spinning cylinder, and extrude and spin at 130°C at a speed of 1mm / s; After the silk is extruded through the spinneret, it enters the hot tunnel at 325°C through an air gap of 11 cm. In the multi-stage stretching device, the thermal stretching ratio is 1, that is, no thermal stretching, the stretching temperature is 380° C., and the winding drum speed is 16.5 cm / s. The fineness of the obtained fiber is 280tex, and the ...

Embodiment 2

[0016] According to the same operating procedure as in Example 1, only the amount of PPEK powder was changed to 66.67g, and the spinning dope with a concentration of 40% was prepared; the dissolution temperature was 145°C; the extrusion speed was 2mm / s, and the extrusion temperature was 145°C; The temperature of the hot tunnel is 325°C, the hot stretching temperature is 380°C, the draw ratio is 3, and the winding drum speed is 26cm / s. The fineness of the obtained fiber is 220tex, and the fiber strength is 270MPa.

Embodiment 3

[0018] According to the same operating procedure of Example 1, only the amount of PPEK powder is changed to 100g, and the spinning stock solution with a concentration of 50% is prepared; the dissolution temperature is 170°C; the extrusion temperature is 145°C; The stretching temperature is 400° C., the draw ratio is 5, and the winding speed is 50 cm / s. The fineness of the obtained fiber is 180tex, and the fiber strength is 287MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com