Spinning method of PEDOT:PSS conductive fiber high in elongation

A high elongation, conductive fiber technology, applied in conductive/antistatic filament manufacturing, wet spinning, conjugated synthetic polymer rayon, etc., can solve environmental pollution, can not fully reflect the advantages of fiber flexibility, fiber Problems such as brittleness and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

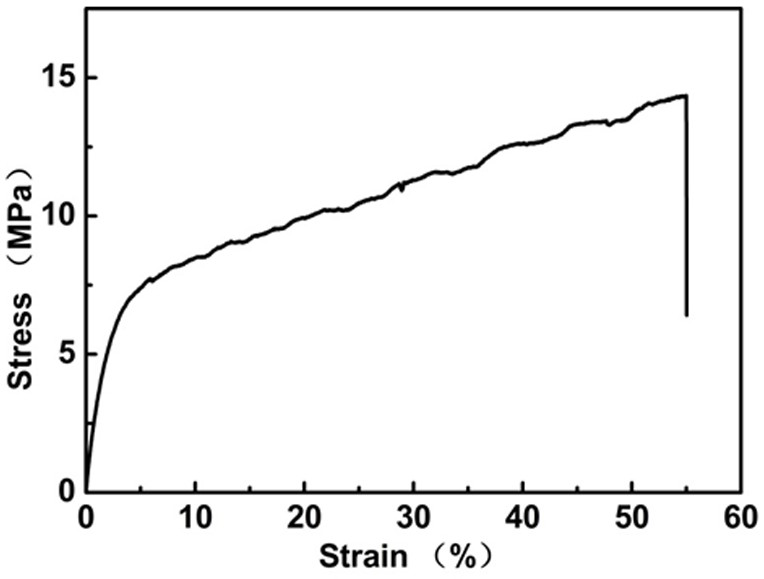

Embodiment 1

[0025] First, prepare the PEDOT:PSS spinning solution: use a heating stirrer to concentrate the PEDOT:PSS aqueous dispersion to 25 mg / ml, and then place the dispersion in an ultrasonic oscillator with a working frequency of 35 KHz for 15 min. Make it into a uniformly dispersed spinning solution, put it into the spinning solution storage tank after standing for defoaming, and the spinneret hole diameter is 0.25 mm;

[0026] Then, prepare coagulation bath, the coagulation bath among the present embodiment is the mixed solution that is made up of ethanol, water and LiCl, and the volume ratio of ethanol and water is 3: 1; The addition concentration of LiCl is 0.1 mol / L. Dissolve LiCl in water first, then add ethanol and stir well for later use;

[0027] Finally, carry out wet spinning: extrude PEDOT:PSS spinning solution at a constant speed, and the advancing speed is 5 ml / h. When the extruded fiber reaches the bottom of the coagulation bath, take it out, dry it with a Teflon roll...

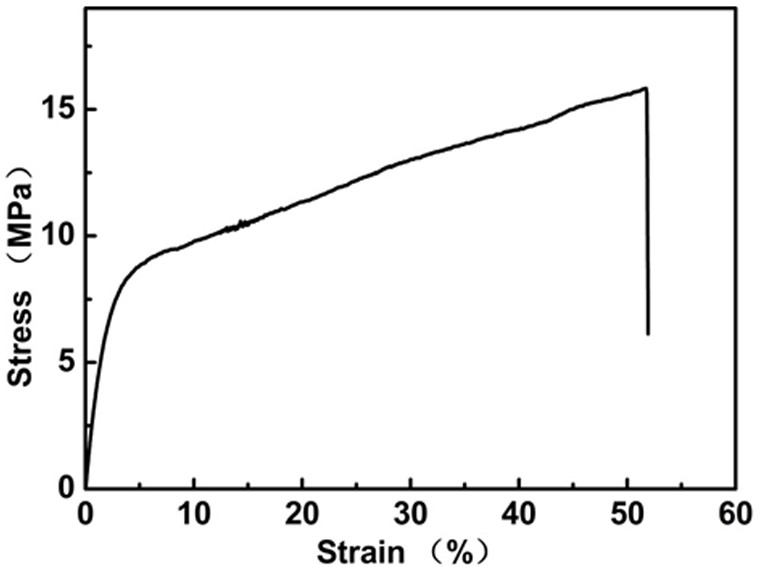

Embodiment 2

[0029] First, prepare the PEDOT:PSS spinning solution: use a heating stirrer to concentrate the PEDOT:PSS aqueous dispersion to 23 mg / ml, and then place the dispersion in an ultrasonic oscillator with a working frequency of 50 KHz for 15 min. Make it into a uniformly dispersed spinning solution, put it into the spinning solution storage tank after standing for defoaming, and the spinneret hole diameter is 0.25 mm;

[0030] Then, prepare coagulation bath, the coagulation bath in the present embodiment is the mixed solution that is made up of ethanol, water and LiCl, and the volume ratio of ethanol and water is 2: 1; The addition concentration of LiCl is 0.1 mol / L. Dissolve LiCl in water first, then add ethanol and stir well for later use;

[0031] Finally, wet spinning: Extrude PEDOT:PSS spinning solution at a constant speed, the advancing speed is 10 ml / h, when the extruded fiber reaches the bottom of the coagulation bath, take it out, dry it with a Teflon roller The drum was...

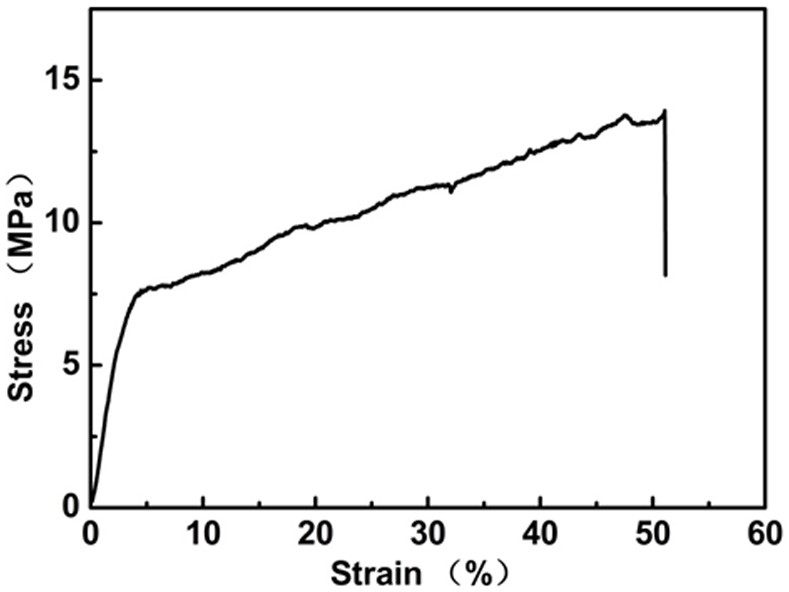

Embodiment 3

[0033] First, prepare the PEDOT:PSS spinning solution: use a heating stirrer to concentrate the PEDOT:PSS aqueous dispersion to 20 mg / ml, and then place the dispersion in an ultrasonic oscillator with a working frequency of 60 KHz for 15 minutes. Make it into a uniformly dispersed spinning solution, put it into the spinning solution storage tank after standing for defoaming, and the spinneret hole diameter is 0.33 mm;

[0034] Then, prepare coagulation bath, the coagulation bath among the present embodiment is the mixed solution that is made up of ethanol, water and LiCl, and the volume ratio of ethanol and water is 5: 1; The addition concentration of LiCl is 0.1 mol / L. Dissolve LiCl in water first, then add ethanol and stir well for later use;

[0035] Finally, carry out wet spinning: extrude PEDOT:PSS spinning solution at a constant speed, and the advancing speed is 5 ml / h. When the extruded fiber reaches the bottom of the coagulation bath, take it out, dry it with a Teflon ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com