Method for mill processing of high-purity and high-density molybdenum alloy target

A dense and molybdenum alloy technology, which is applied in high-density molybdenum alloy targets, molybdenum alloy targets for coating, and high-purity rolling processing, can solve the problems that deformation processing cannot be carried out, and active metal components are difficult to restore. The effect of shortening the processing cycle, improving production efficiency and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

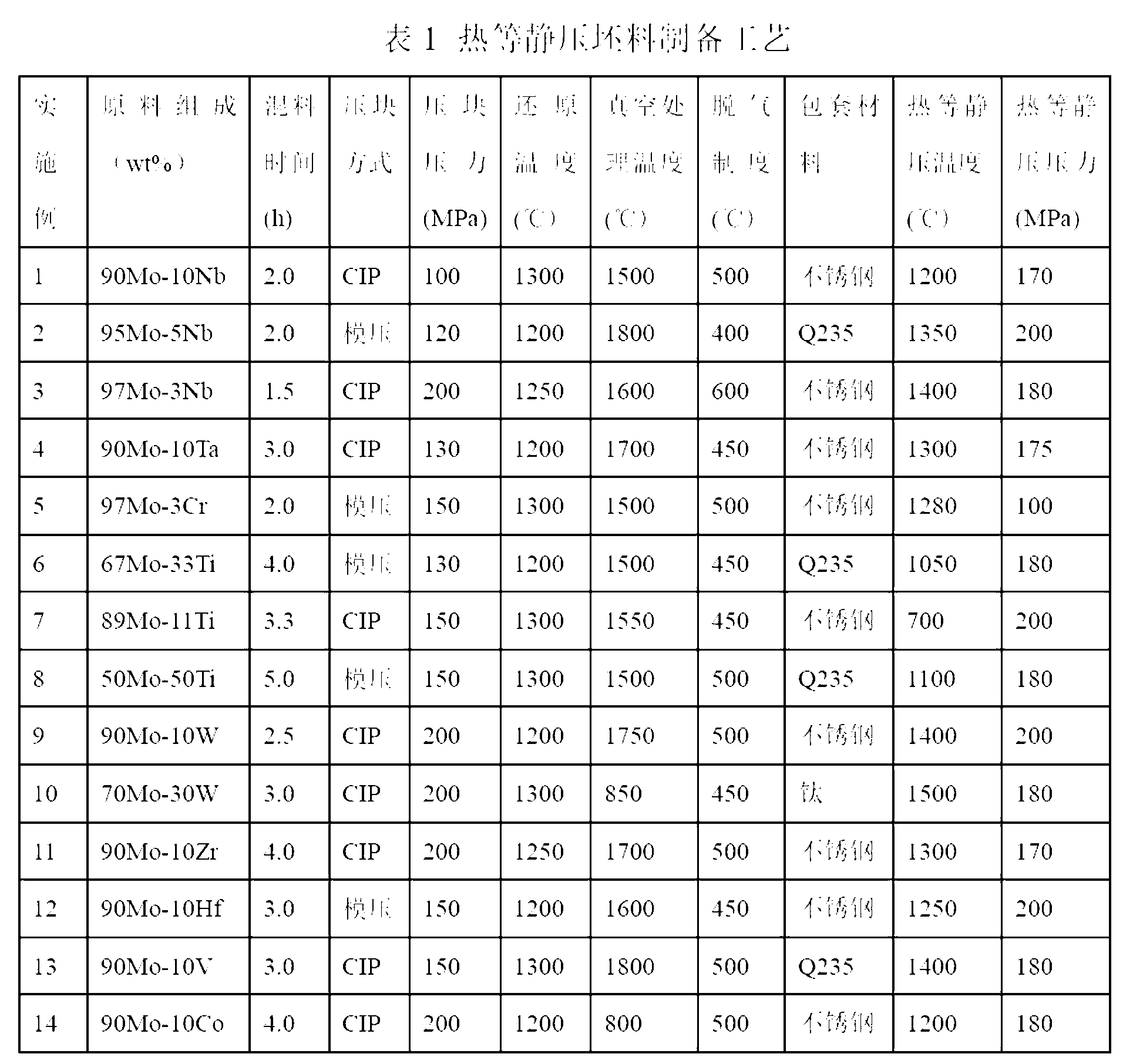

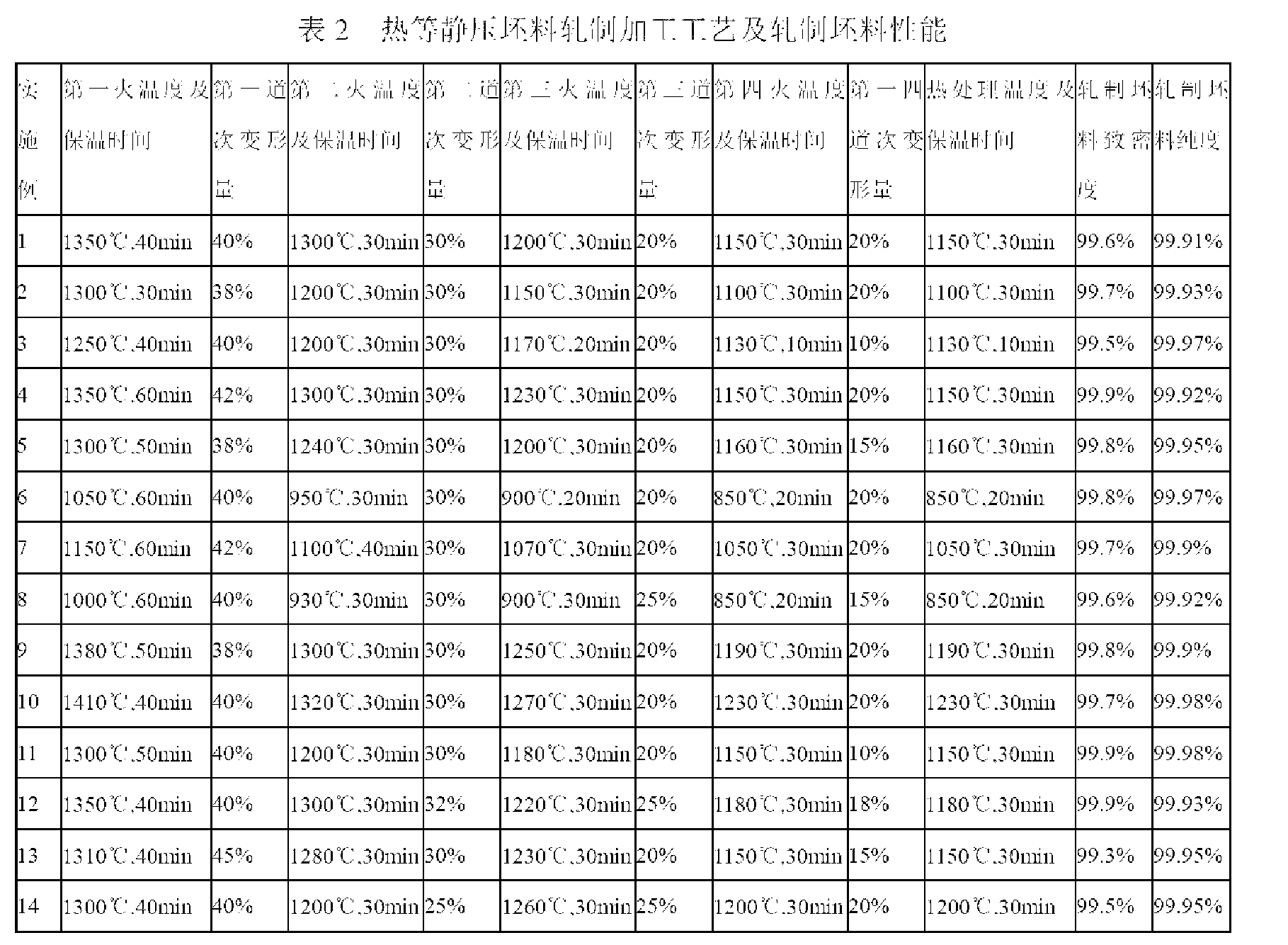

[0023] Select molybdenum powder with a Fischer particle size of 2.8 μm and a purity of 99.9%, niobium powder with a particle size of -100 mesh and a purity of 99.95%, tantalum powder with a particle size of -100 mesh and a purity of 99.95%, titanium powder with a particle size of -200 mesh and a purity of 99.8%, Particle size -200 mesh, chromium powder with a purity of 99.9%, Fischer particle size of 6 μm, tungsten powder with a purity of 99.9%, particle size -100 mesh, zirconium powder with a purity of 99.9%, particle size -200 mesh, hafnium powder with a purity of 99.9%, particle size - 200 mesh, vanadium powder with a purity of 99.9% and cobalt powder with a Fischer particle size of 3 μm and a purity of 99.9% are used as raw materials. Table 1 lists the hot isostatic pressing billet preparation process parameters of Examples 1-14, and Table 2 lists the hot isostatic pressing billet rolling process parameters and rolling billet performance parameters of Examples 1-14.

[002...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com