Automatic analysis method for COD in sea water

A chemical oxygen demand, automatic analysis technology, applied in the direction of material analysis, material analysis, testing water, etc. through optical means, can solve the problems of inability to use chemical oxygen demand automatic analysis, labor-intensive, cumbersome operation, etc. Good recovery rate, strong anti-interference ability, good matching effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

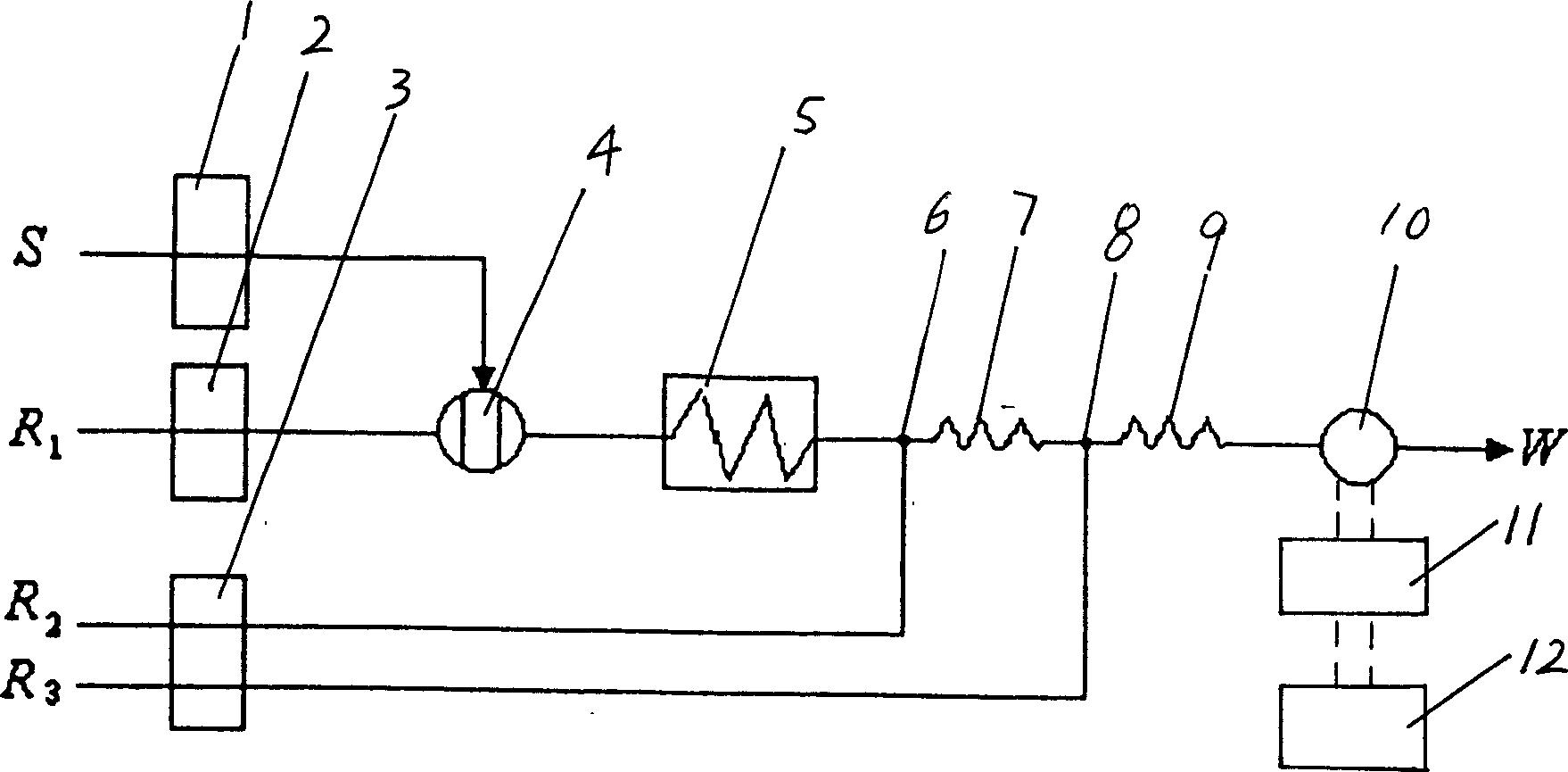

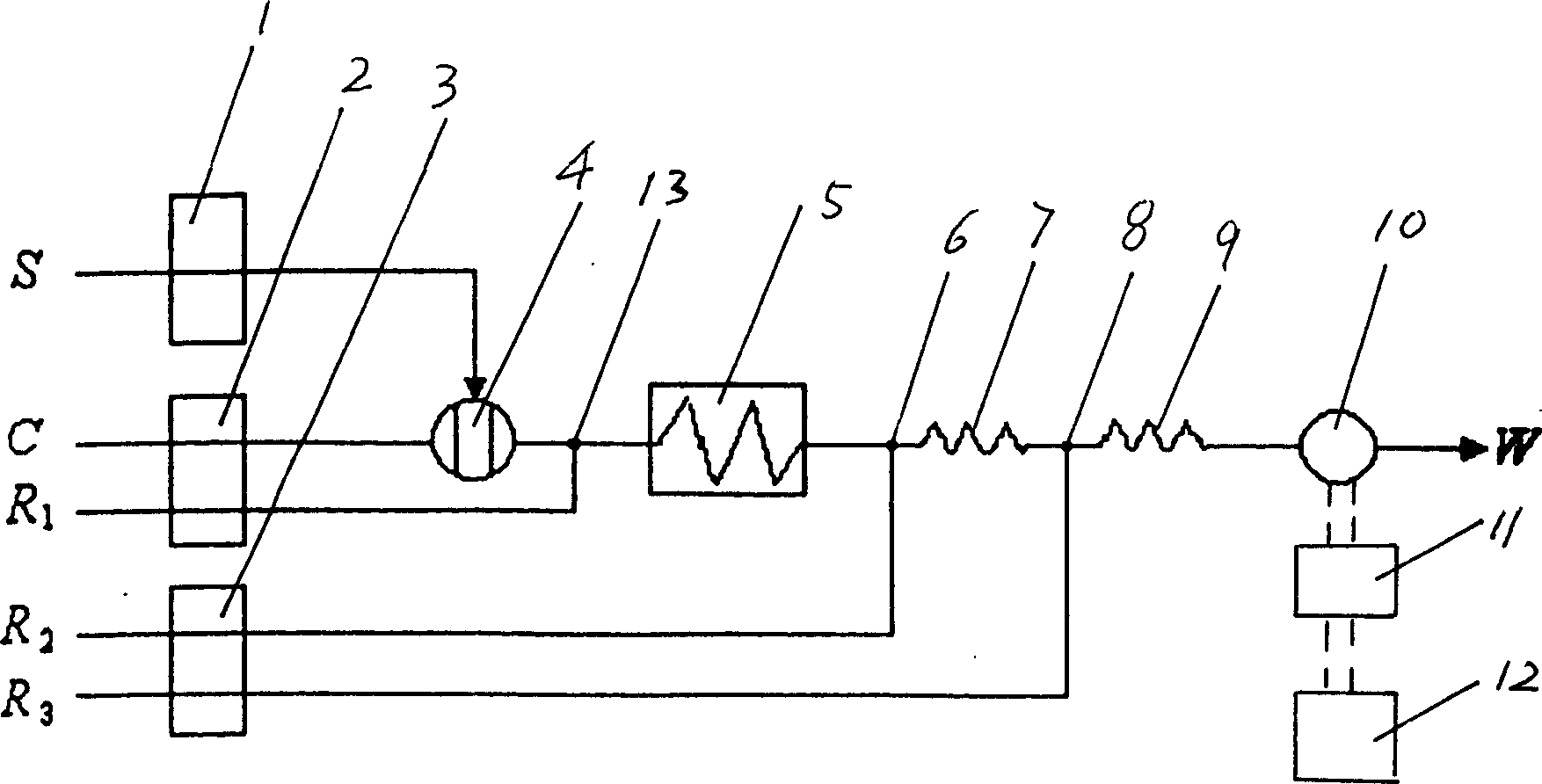

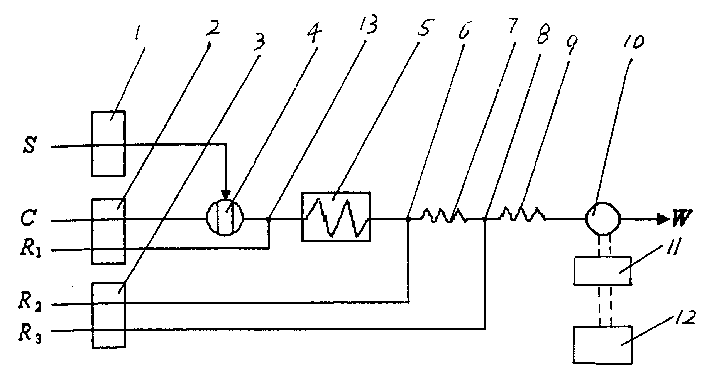

Method used

Image

Examples

Embodiment 1

[0022] 1. Preparation of standard samples

[0023] (1) take glucose and be made into 1000mg / L COD standard aqueous solution as mother liquor;

[0024] (2) Dilute the mother liquor and prepare a series of standard samples. 6.0mg / L, 7.0mg / L, 8.0mg / L, 9.0mg / L, 10.0mg / L.

[0025] 2. Preparation of oxidizing solution

[0026] KMnO 4 After dissolving and diluting with distilled water, boil for 40-60 minutes, keep away from light, place overnight, and filter to make 3.6×10 -4 mol / L KMnO 4 Stock solution; dissolve NaOH in distilled water to configure a 2.5mol / L NaOH stock solution; take KMnO 4 Stock solution and NaOH stock solution were diluted with distilled water to prepare KMnO 4 The concentration is 6.0×10 -5 mol / L, the concentration of NaOH is 0.05mol / L oxidation solution.

[0027] 3. Preparation of acidizing solution

[0028]Slowly add concentrated sulfuric acid into water under stirring to form (1+3) sulfuric acid solution, dilute (1+3) sulfuric acid solution with wate...

Embodiment 2

[0040] 1. Preparation of standard samples

[0041] Same as Example 1.

[0042] 2. Preparation of oxidizing solution

[0043] KMnO 4 After dissolving and diluting with distilled water, boil for 40-60 minutes, keep away from light, place overnight, and filter to make 3.6×10 -4 mol / L KMnO 4 Stock solution; dissolve NaOH in distilled water to configure a 2.5mol / L NaOH stock solution; take KMnO 4 Stock solution and NaOH stock solution were diluted with distilled water to prepare KMnO 4 The concentration is 8.0×10 -5 mol / L, the concentration of NaOH is 0.06mol / L oxidation solution.

[0044] 3. Preparation of acidizing solution

[0045] Slowly add concentrated sulfuric acid into water under stirring to form (1+3) sulfuric acid solution, dilute (1+3) sulfuric acid solution with water to form 0.6mol / L H 2 SO 4 solution.

[0046] 4. Configuration of reduction chromogenic solution

[0047] Add a certain amount of soluble starch into distilled water and boil until the solution ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com