Surface crack detection method and system

A detection method and technology for surface cracks, applied in the field of detection methods and systems for surface cracks, can solve the problems of low crack detection efficiency, long time consumption, large amount of calculation, etc., so as to improve the calculation efficiency and improve the efficiency and repeatability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

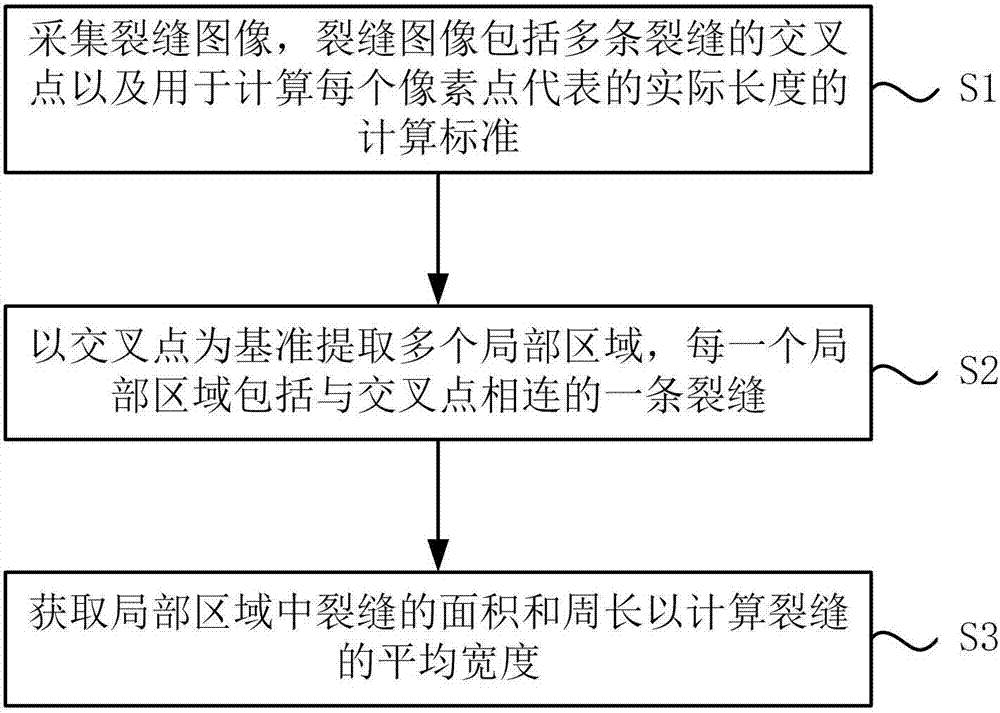

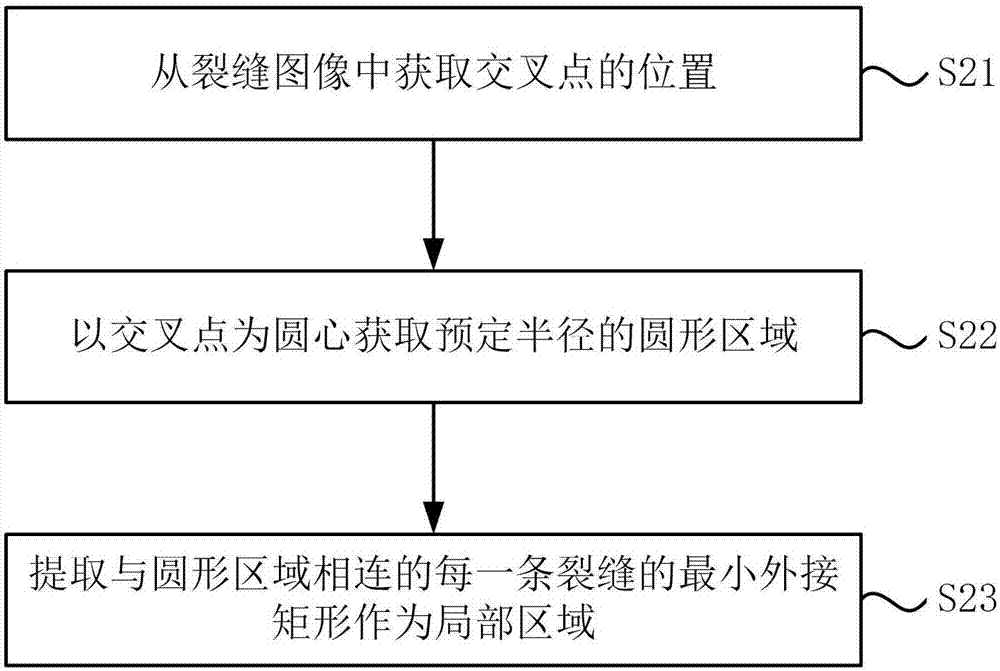

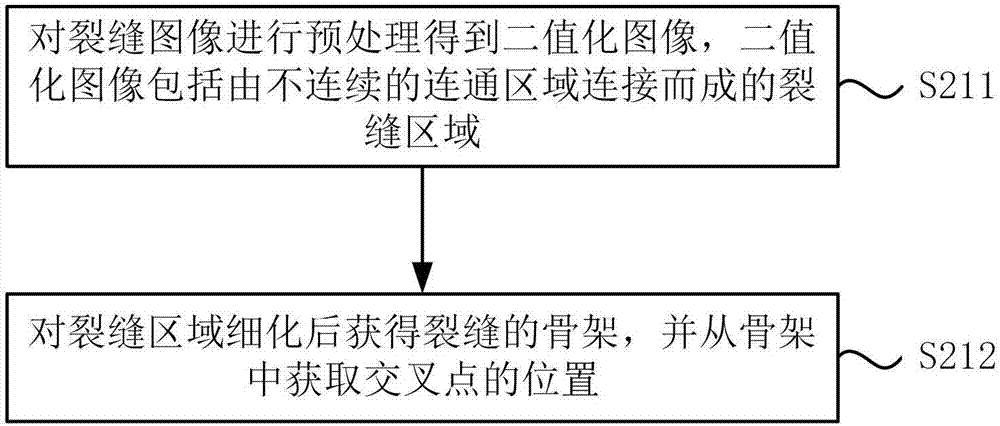

[0046] see figure 1 As shown, the embodiment of the present invention provides a detection method for surface cracks, comprising the following steps:

[0047] S1. Collecting a crack image, the crack image includes intersection points of multiple cracks and a calculation standard used to calculate the actual length represented by each pixel point.

[0048] The crack image collected is a digital image. In order to use the digital image to measure the crack size, it is necessary to know the actual length δ represented by each pixel of the crack image, that is, the pixel point Calibration, its unit is mm / pix. The commonly used pixel point calibration method is to stick a black paper strip of known length near the crack to be photographed. After preprocessing the crack image, the number of pixels along the length of the paper strip can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com