Microscopic welding micro-tensile measuring instrument

A tensile force measurement and tensile force technology, which is applied in the field of small-scale tensile force measurement devices, can solve problems such as failure to meet tensile measurement requirements, and achieve the effects of improving tensile force measurement accuracy, reducing working distance, and reducing manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

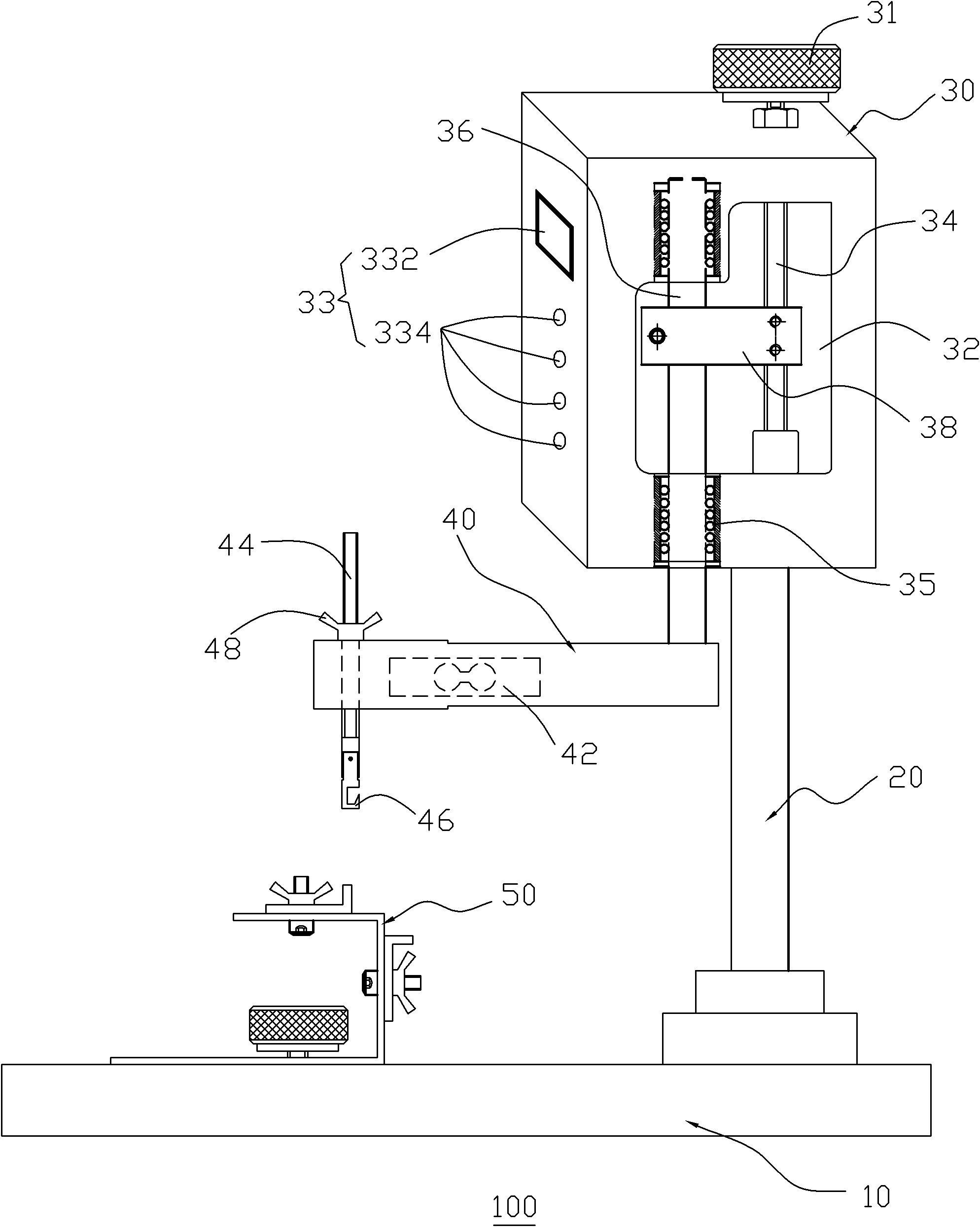

[0012] The purpose of the present invention is mainly to provide a kind of accurate measuring device for the tensile strength measurement of the welding joint of micro-workpieces in resistance welding microscopic welding, its measuring range is generally below 2 kilograms, and the measuring accuracy reaches ± 1g. At the same time, the present invention is also applicable to measuring the tensile strength of various small objects, such as the measurement of the adhesive force of the small-area bonding surface of viscose, and the tensile strength measurement of various thin metal wires, small metal strips or fine enameled wires. Strength is measured. Therefore, the present invention can also be referred to as a micro tension measuring instrument for short.

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

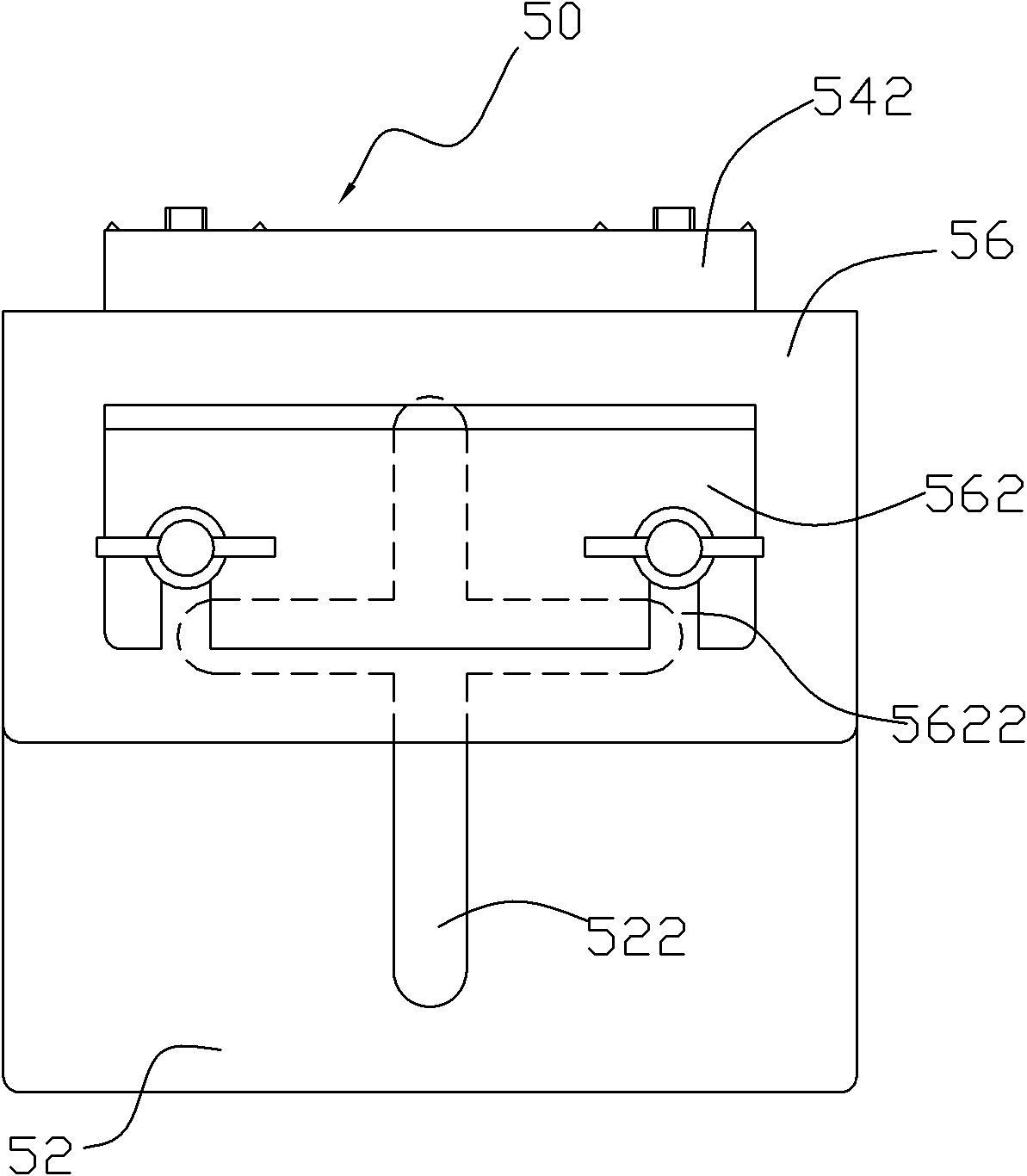

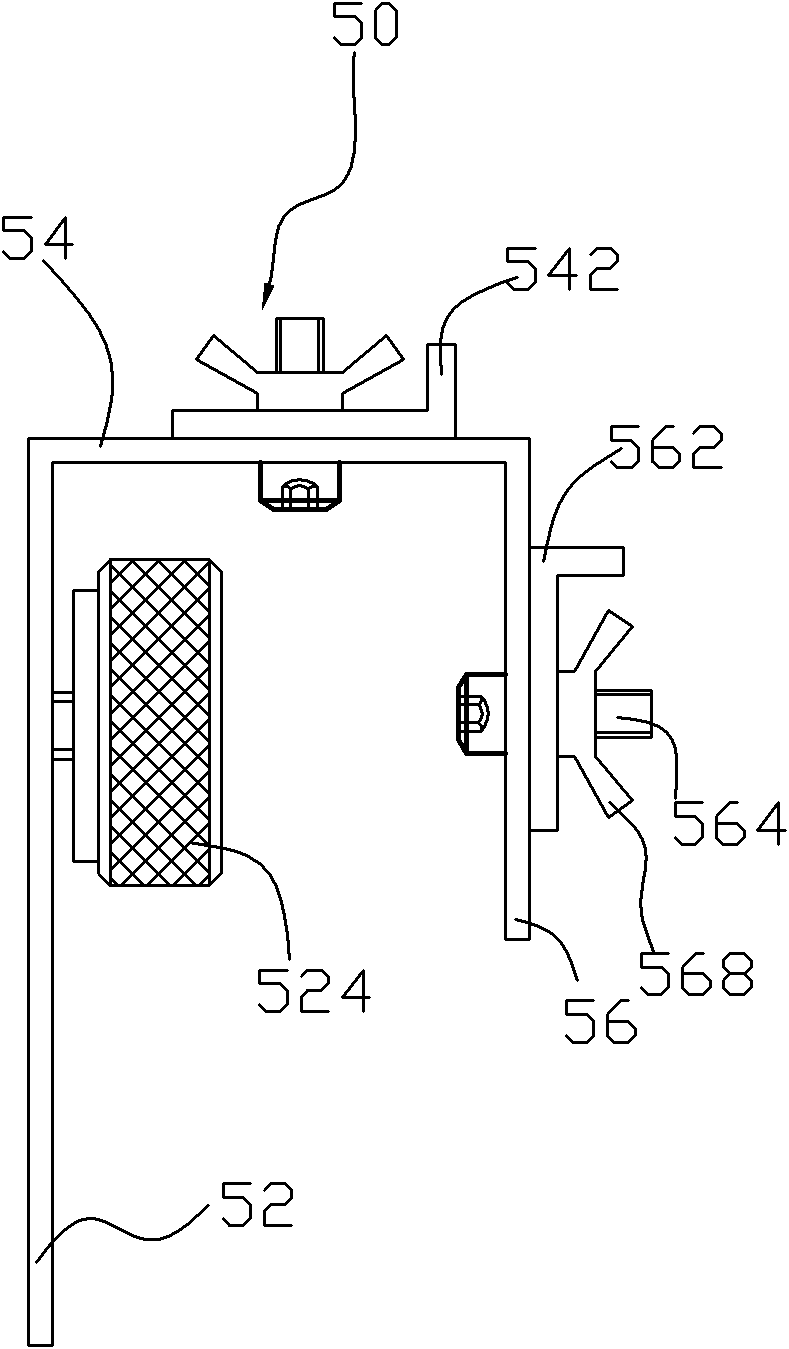

[0014] refer to Figure 1-3 , according to one embodiment of the present invention, a micro-weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com