Objective lens light window flange and vacuum cavity using the flange

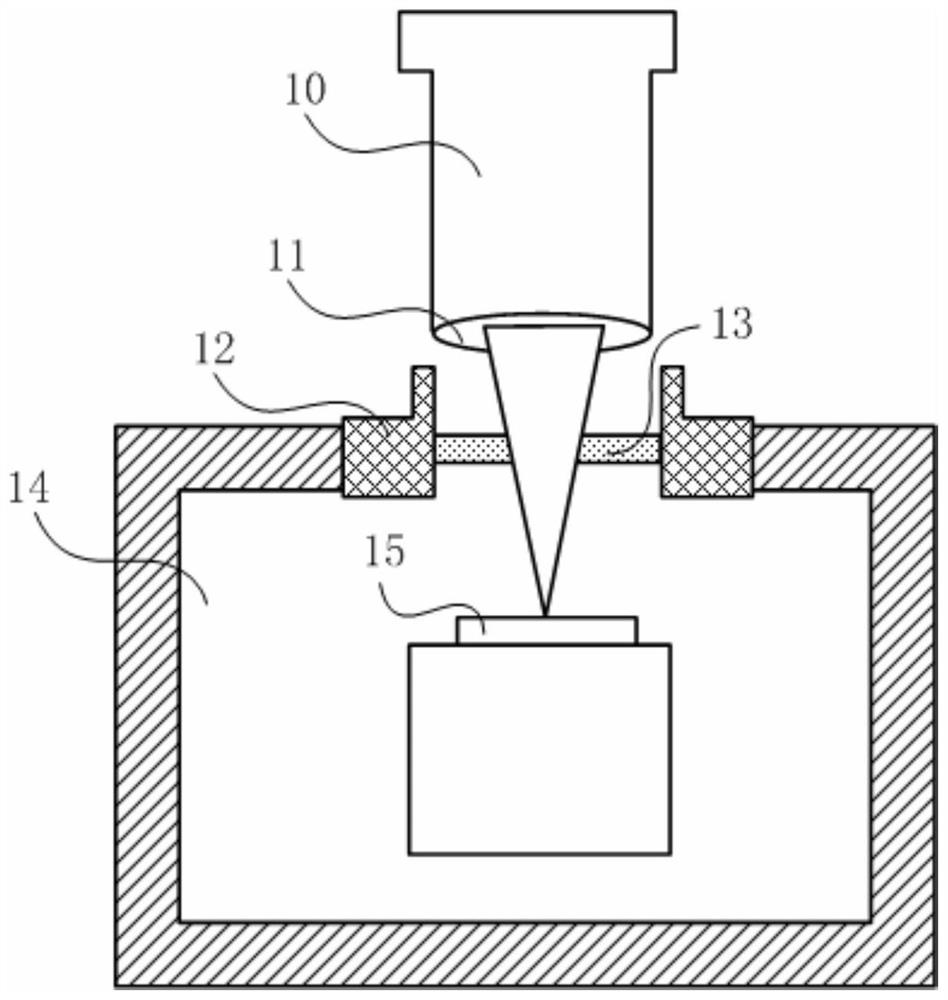

A technology of objective lens and light window, which is applied in the field of vacuum cavity, can solve the problems of small numerical aperture of objective lens, low resolution, long working distance of objective lens, etc., and achieve the effect of shortening working distance, high resolution and large numerical aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

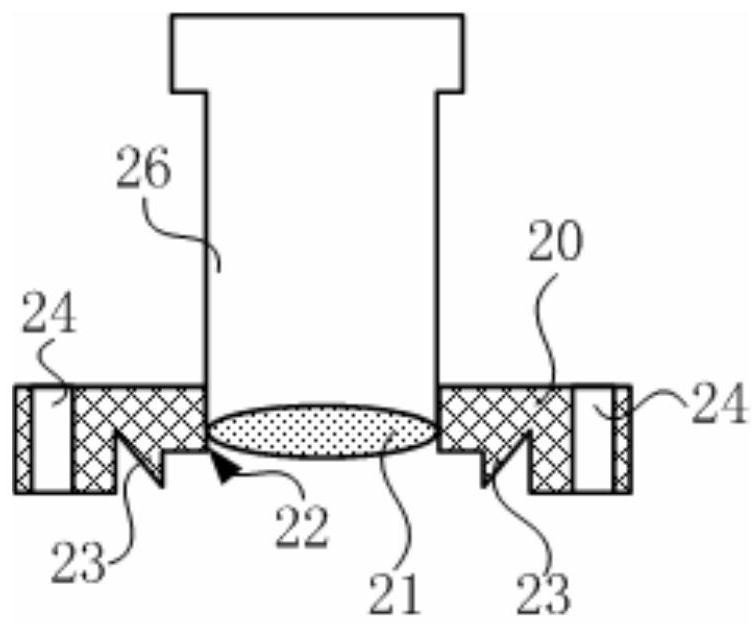

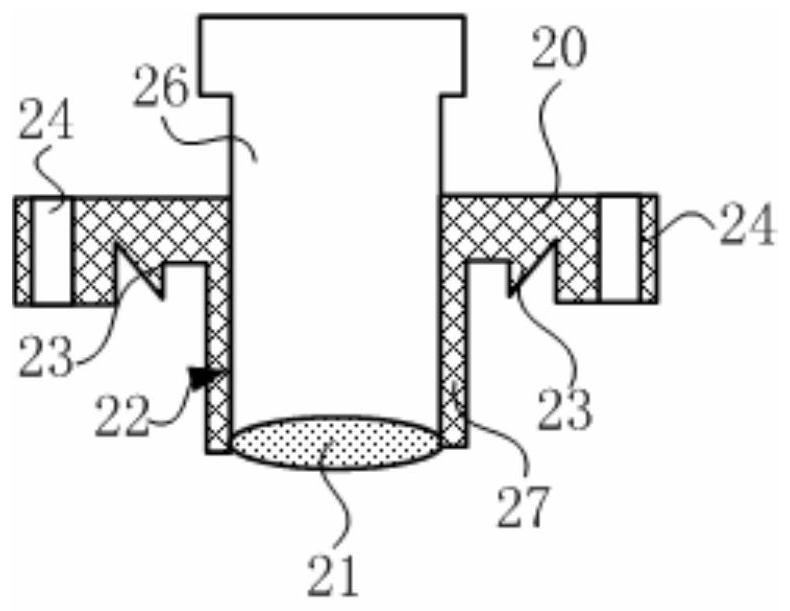

[0023] Below in conjunction with accompanying drawing, the specific embodiment of the objective lens light window type flange that the present invention provides is described in detail, wherein in order to clearly describe the technical scheme of the present invention, the size of part structure is exaggerated, and it does not represent the actual size of this structure, accompanying drawing It is only used to show the connection relationship between the various structures.

[0024] figure 2 It is a structural schematic diagram of the first embodiment of the objective lens light window type flange of the present invention. see figure 2 , The objective lens light window flange of the present invention includes a flange plate 20 and a lens 21 .

[0025] The flange 20 is connected with the external device to fix the flange on the external device. In this embodiment, the flange 20 is provided with a plurality of connecting holes 24 . Connecting member 25 (shown in Figure 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com