Micro tensile measurement unit and production method thereof

A technology for measuring components and manufacturing methods, which is applied in the direction of measuring devices, piezoelectric devices/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., and can solve problems such as complex manufacturing processes and performance degradation of mechanical sensors , to achieve the effect of simple and easy operation, overcome the thick glue process and microstructure planarization technology, and reduce the production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be further described below in conjunction with a preferred embodiment and the accompanying drawings.

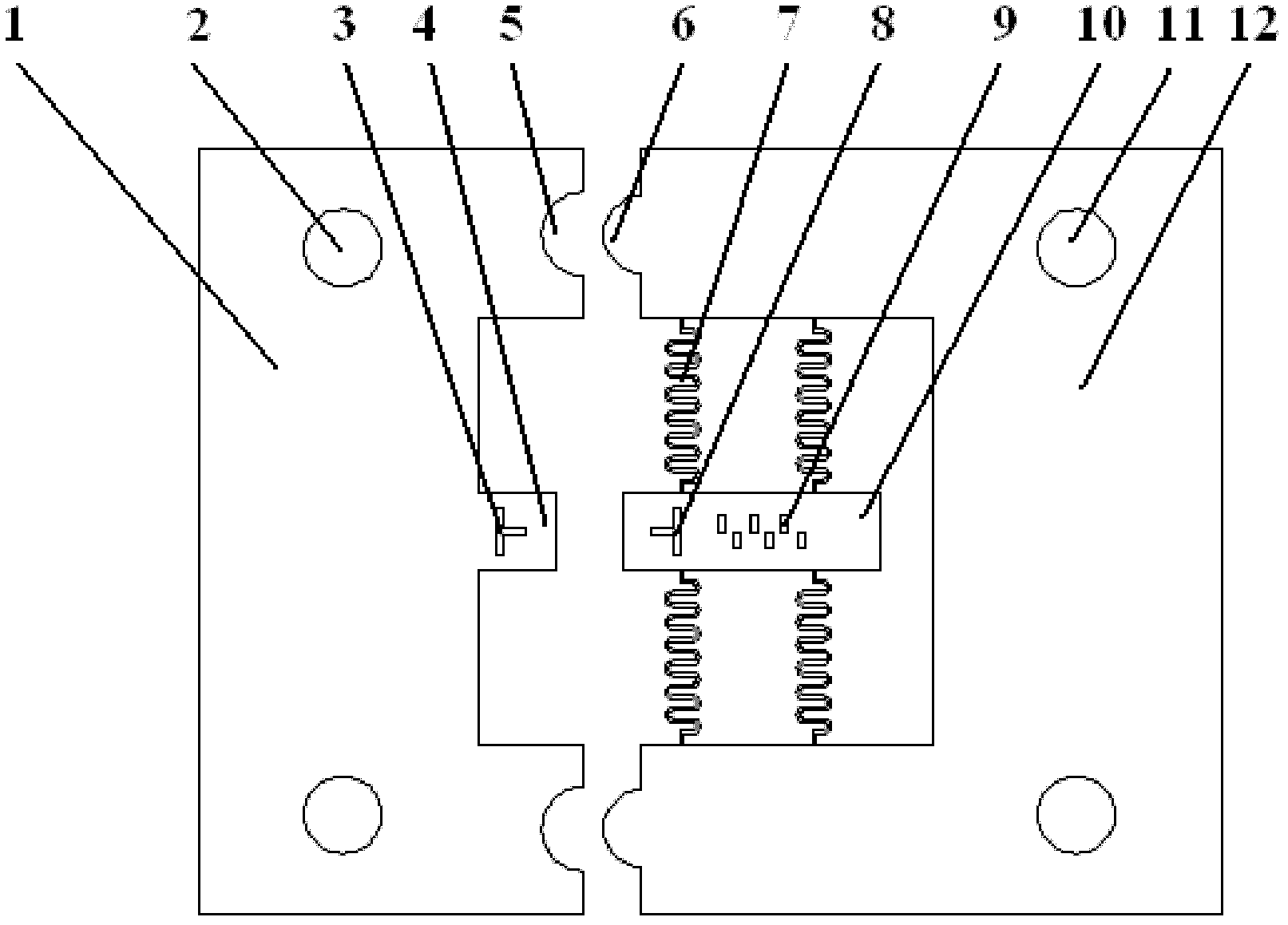

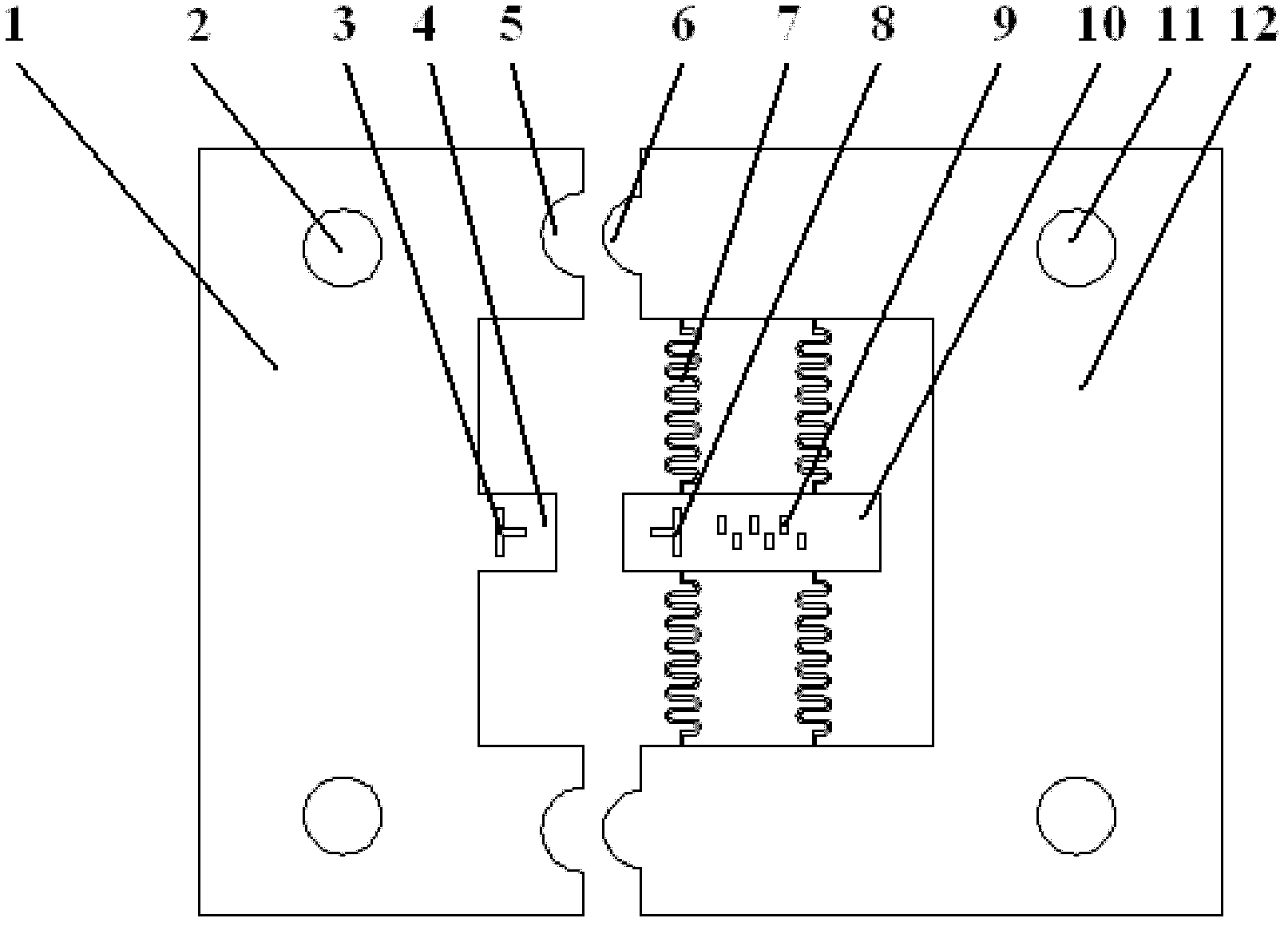

[0030] refer to figure 1 , the micro-tensile measurement assembly is made of stainless steel 301, including a fixed platform 1 and a mobile platform 12, wherein the fixed platform 1 is provided with a positioning hole 2, an alignment groove 5 and a sample fixed platform 4, and the sample fixed platform 4 There is a sample centering mark 3 on it; a plurality of curved springs 7 for sensing loads, positioning holes 11, alignment bumps 6 and a sample fixing platform 10 are distributed on the mobile platform 12, and the sample fixing platform 10 is provided with Sample alignment marker 8 and displacement marker 9. The aforementioned positioning holes 2 and 11 are respectively used for fixing the fixed platform and the mobile platform.

[0031] The aforementioned alignment groove 5 cooperates with the alignment protrusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Line width | aaaaa | aaaaa |

| Number of turns | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com