Low-temperature tab adhesive and preparation method thereof

A technology of ear glue and low temperature, applied in adhesives, final product manufacturing, sustainable manufacturing/processing, etc., can solve problems such as inapplicability, achieve the effect of ensuring stiffness, ensuring bonding strength, and reducing packaging temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

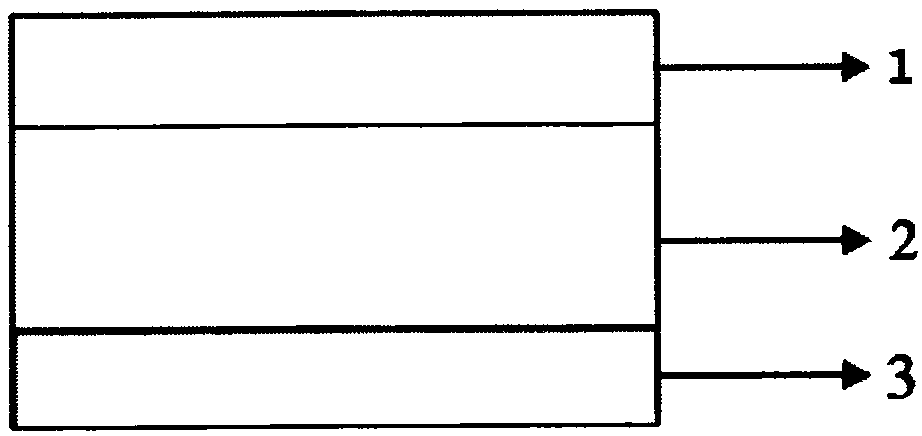

[0030] figure 1 It is a schematic diagram of the structure of low-temperature tab glue. The low-temperature tab glue includes a first acid-modified resin outer layer 1, a tab rubber core layer 2, a second acid-modified resin outer layer 3, and the tab rubber core layer 2 is provided on the first Between an acid-modified resin outer layer 1 and a second acid-modified resin outer layer 3, the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are sequentially compounded together.

[0031] The melting points of the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are 101°C, 142°C, and 101°C, respectively.

[0032] The thickness ratio is: the first acid-modified resin outer layer 1: the lug rubber core layer 2: the second acid-modified resin outer layer 3=1:3:1, the first acid-modified resin outer layer 1, the lug rubber core layer 2 The total thickn...

Embodiment 2

[0044] figure 1 It is a schematic diagram of the structure of low-temperature tab glue. The low-temperature tab glue includes a first acid-modified resin outer layer 1, a tab rubber core layer 2, a second acid-modified resin outer layer 3, and the tab rubber core layer 2 is provided on the first Between an acid-modified resin outer layer 1 and a second acid-modified resin outer layer 3, the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are sequentially compounded together.

[0045] The melting points of the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are 139°C, 164°C, and 139°C, respectively.

[0046] The thickness ratio is: the first acid-modified resin outer layer 1: the lug rubber core layer 2: the second acid-modified resin outer layer 3=1:6:1, the first acid-modified resin outer layer 1, the lug rubber core layer 2 The total thickn...

Embodiment 3

[0058] figure 1 It is a schematic diagram of the structure of low-temperature tab glue. The low-temperature tab glue includes a first acid-modified resin outer layer 1, a tab rubber core layer 2, a second acid-modified resin outer layer 3, and the tab rubber core layer 2 is provided on the first Between an acid-modified resin outer layer 1 and a second acid-modified resin outer layer 3, the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are sequentially compounded together.

[0059] The melting points of the first acid-modified resin outer layer 1, the tab rubber core layer 2, and the second acid-modified resin outer layer 3 are 139°C, 164°C, and 139°C, respectively.

[0060] The thickness ratio is: the first acid-modified resin outer layer 1: the lug rubber core layer 2: the second acid-modified resin outer layer 3=1:4:1, the first acid-modified resin outer layer 1, the lug rubber core layer 2 The total thickn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com