Vertical micro-tensile isolation bearing

A seismic-isolating bearing and micro-stretching technology, which is applied in the directions of earthquake resistance, building components, building types, etc., can solve the problems of tensile damage of rubber bearings, large tensile pressure at the edge of the structure, weak tensile and compressive performance, etc. , to achieve the effect of improving the anti-overturning ability, solving the tensile stress over-limit, and strong anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

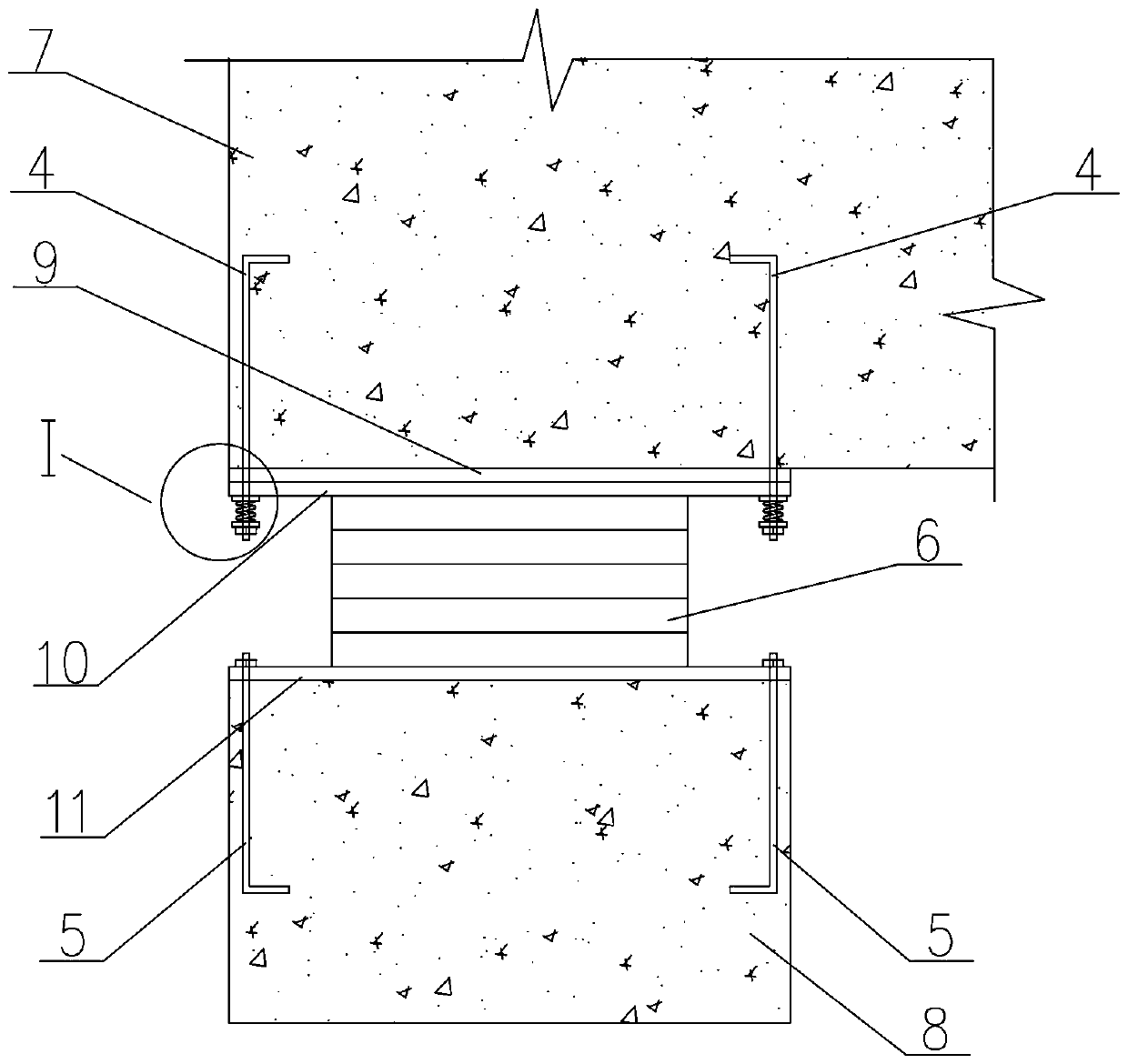

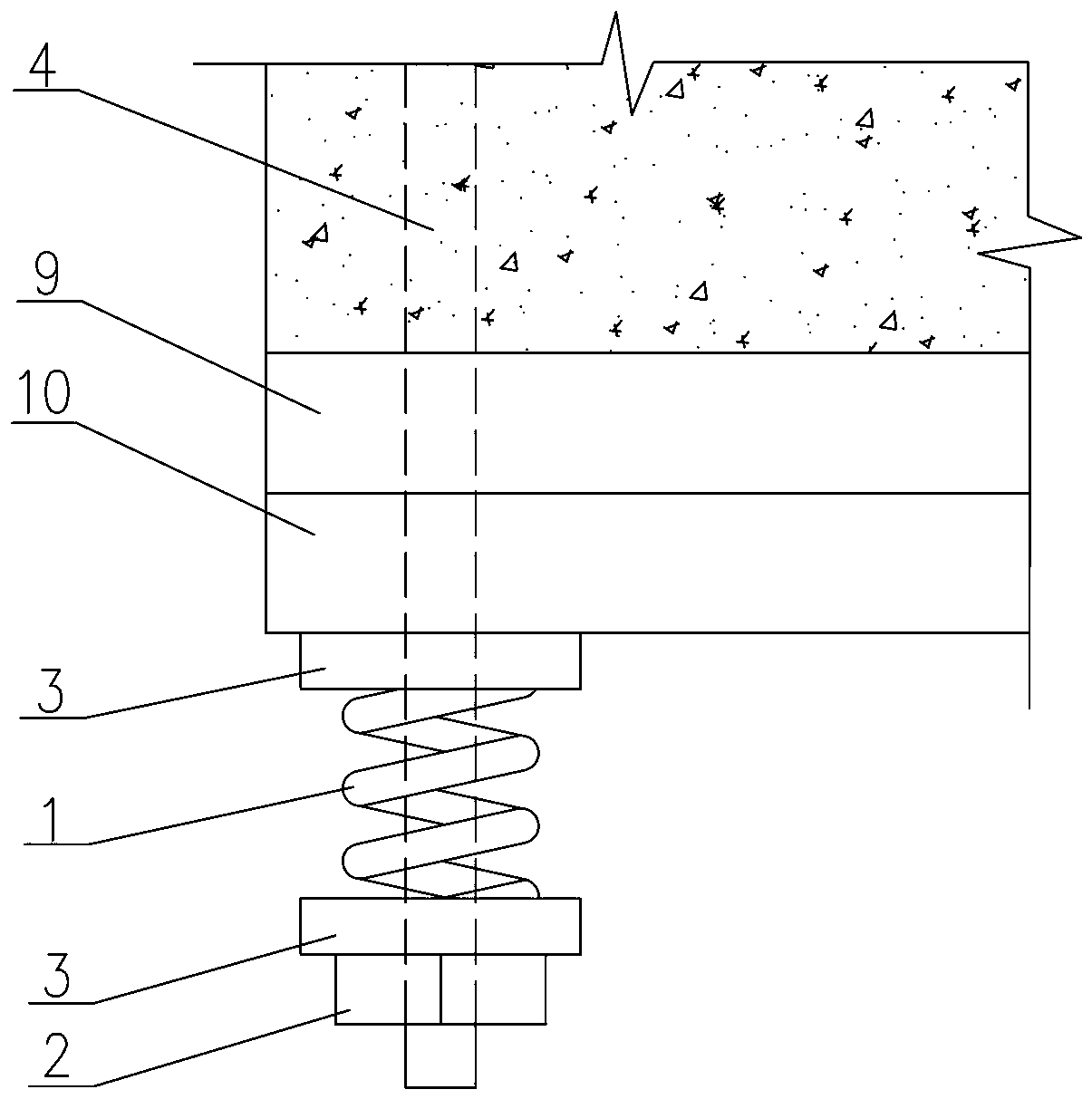

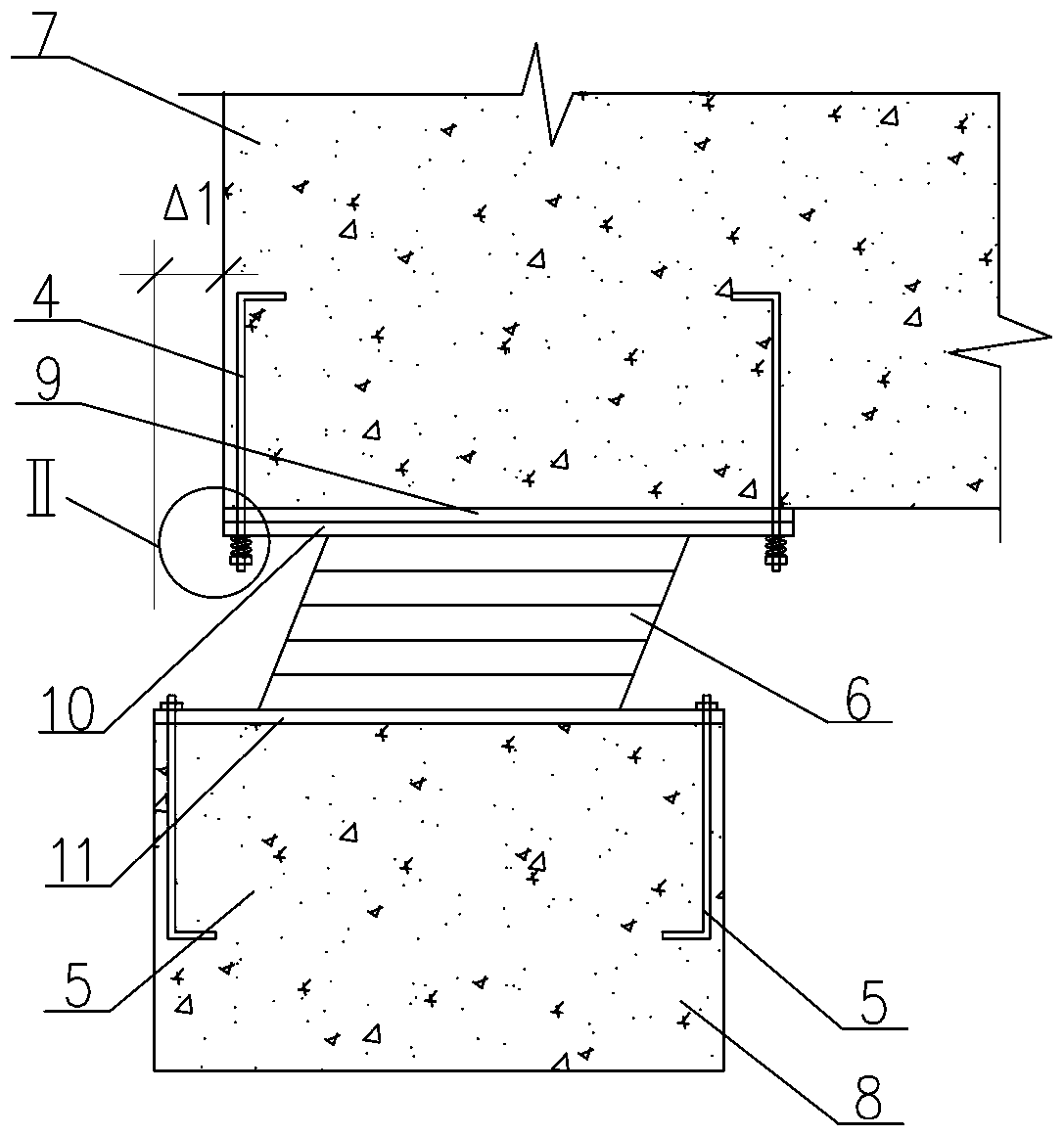

[0012] See attached figure 1 ~ attached figure 2 , the present invention is composed of a rubber shock-isolation support 6 arranged between the support top plate 10 and the support bottom plate 11, and the support top plate 10 is arranged under the embedded steel plate 9 fixedly connected with the upper shock-isolation layer structure 7 ; The upper shock-isolation layer structure 7 is provided with an upper embedded bolt 4; the upper embedded bolt 4 passes through the embedded steel plate 9 and the support top plate 10 in turn, and then the compression spring 1 is set, and the limit nut 2 Fastened with the upper embedded bolt 4 to form a vertical micro-tensioning device; the vertical micro-tensioning device is several and symmetrically arranged on the upper shock-isolation layer structure 7; The tightening force is crimped with the embedded steel plate 9; gaskets 3 are provided at both ends of the compression spring 1; the support bottom plate 11 is anchored and connected wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com