Construction method of embedded assembly type H-shaped steel framework hidden type stone masonry walls

A construction method, H-shaped steel technology, applied to building structures, protected buildings/shelters, walls, etc., can solve problems such as weak seismic performance, ecological environment damage in plateau areas, unfavorable preservation of Tibetan style stone masonry areas, etc. , to achieve the effect of fast construction, saving concrete curing time, and good anti-overturning ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A method for building a built-in assembled H-shaped steel skeleton Tibetan-style stone wall, comprising the following steps:

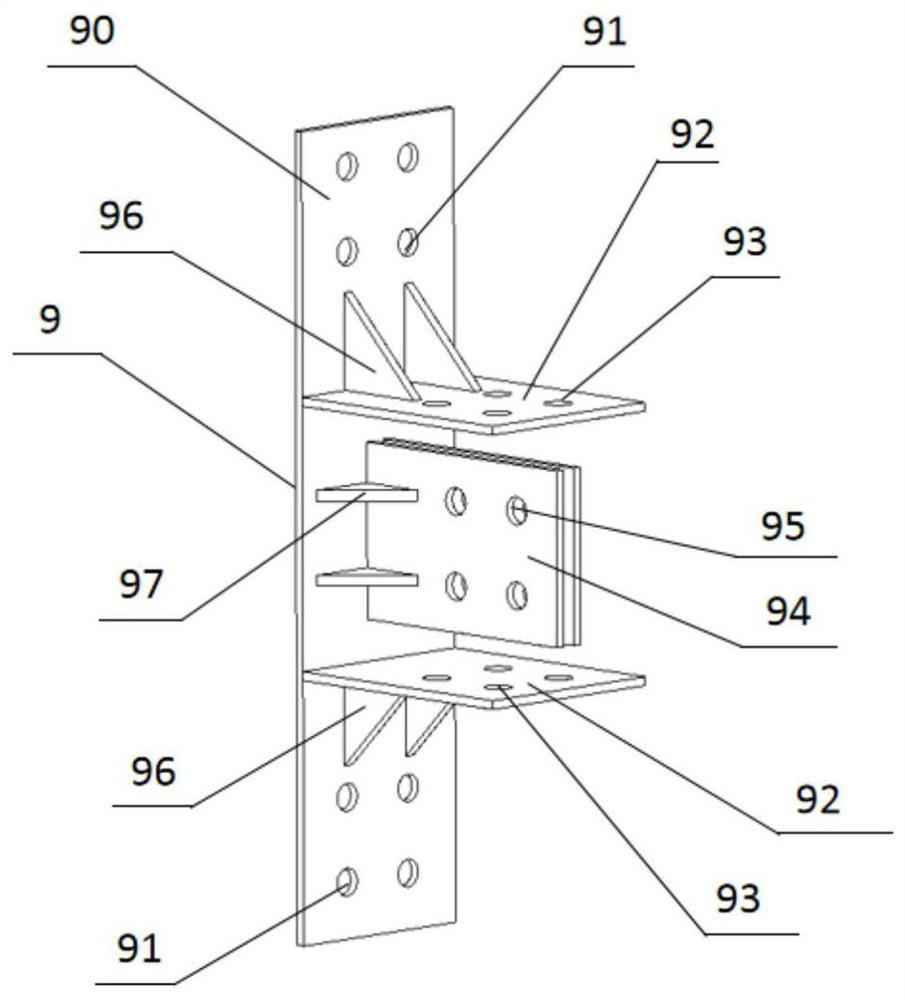

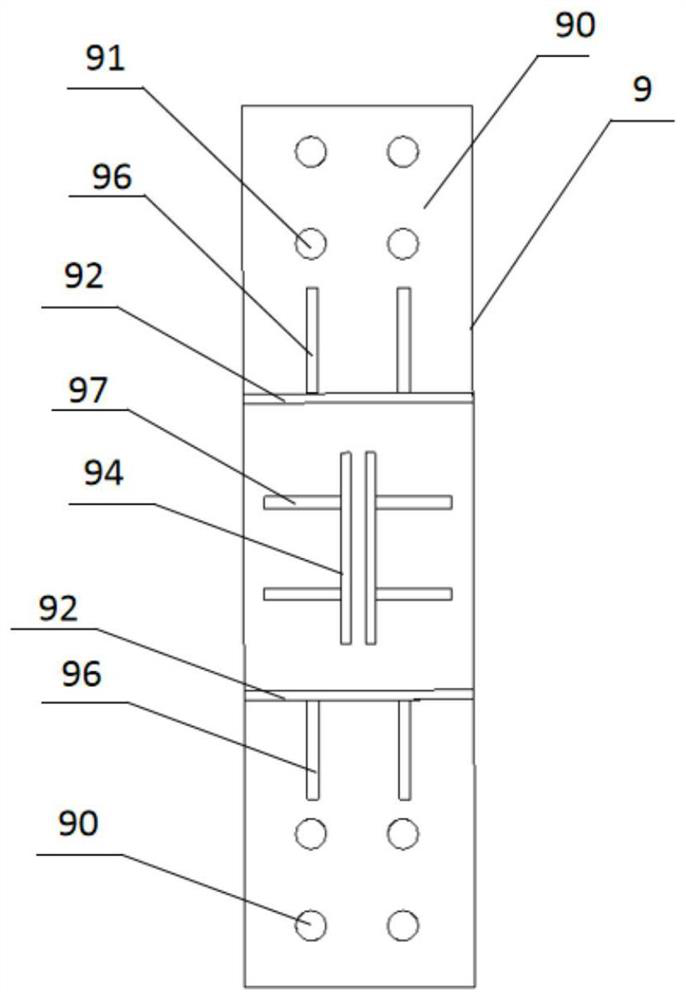

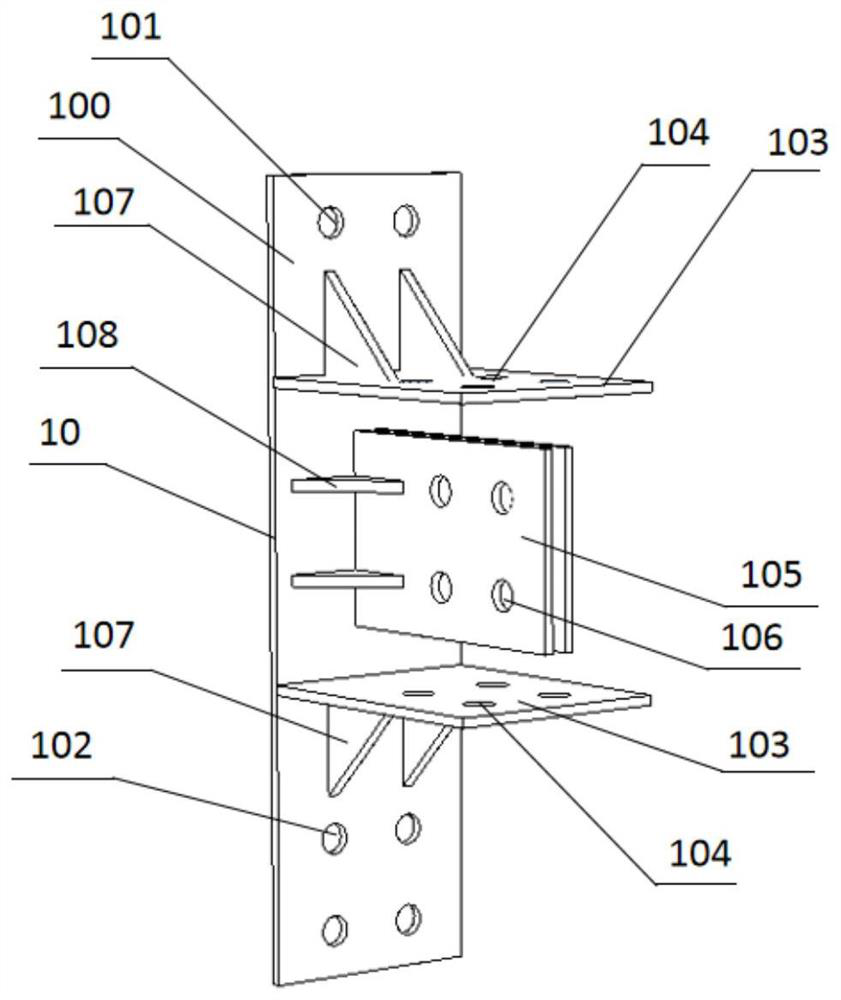

[0043] Step 1, such as Figure 1-17 As shown, on the stone foundation or cast-in-place ground beam 1, anchor bolts 2 are used to fix the embedded connector 3, and the H-shaped steel A 4 of model HM200×150 is vertically placed on the embedded connector 3, and the H-shaped steel A Bolted with pre-embedded connectors to form column feet; after the connection is fixed, stone masonry is built. The stones around vertical H-shaped steel A are built in the way of rubble and flakes. Vertical H-shaped steel A and stone The wall 7 is connected, and around the vertical H-shaped steel A, roughly square, flat and suitable size flakes are placed parallel to the flange of the steel. The thickness of the flakes should be 3-8mm, and the length and width should be between 20-40cm. Small stones are filled between the flakes and poured with high-viscosity loess. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com