Mooring foundation with multiple lines of steel piles and waste tires symmetrically distributed and construction method of mooring foundation

A technology of waste tires and symmetrical distribution, applied in the field of mooring systems, can solve problems such as anchorage and damage, and achieve the effects of low construction cost, simple construction and high rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

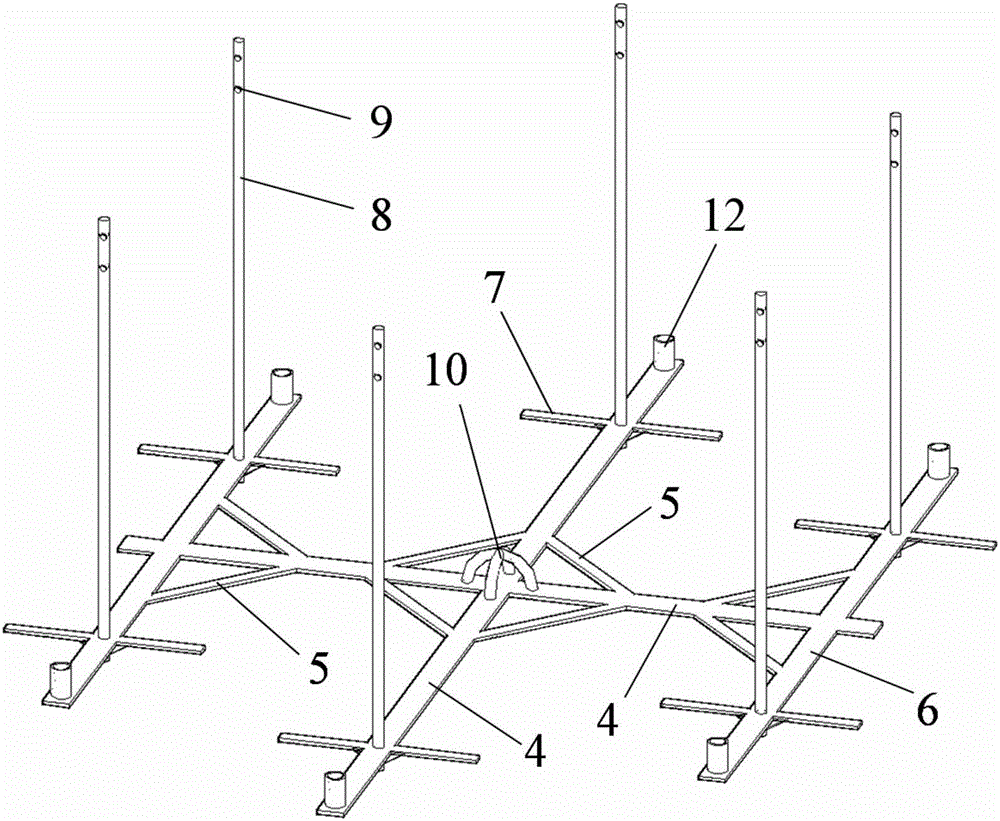

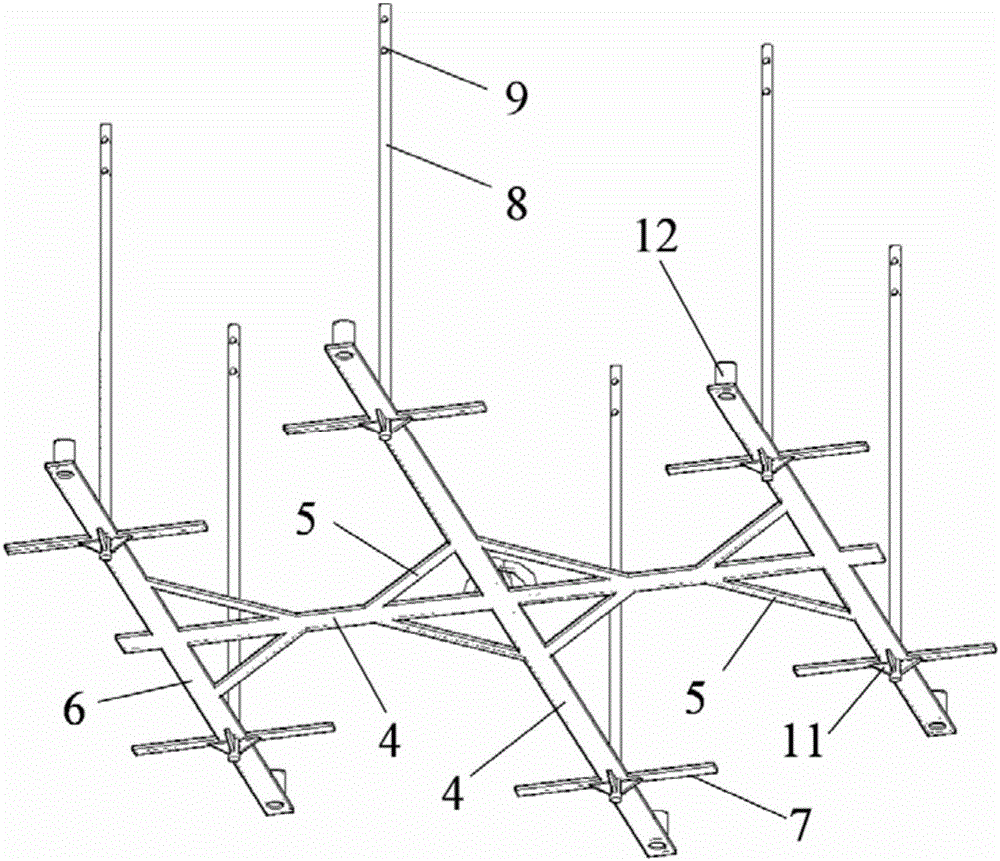

[0036] See attached picture:

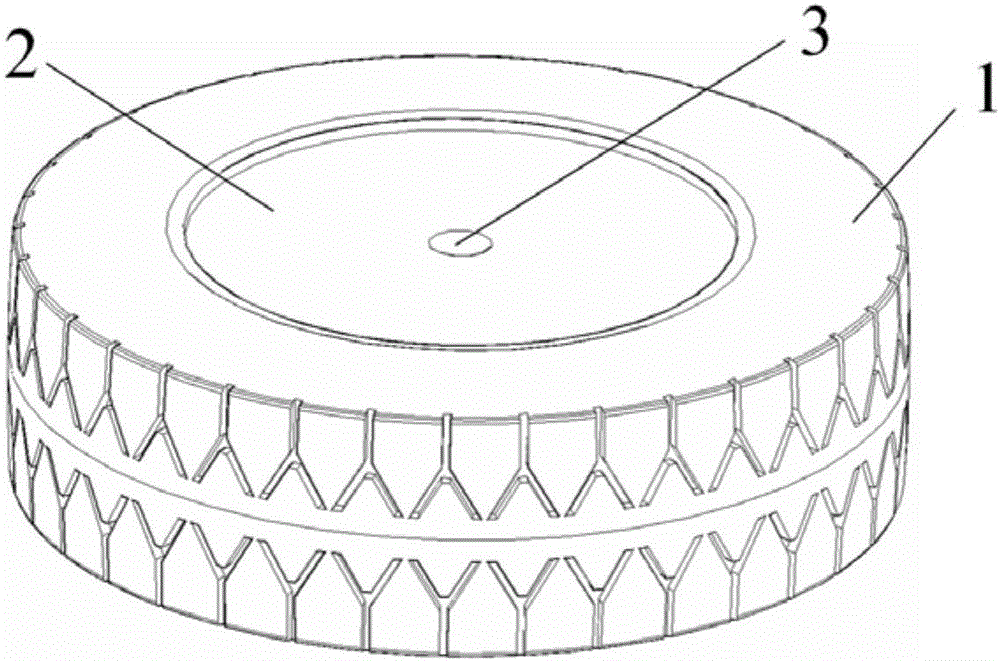

[0037] A mooring foundation with multiple rows of steel piles and waste tires symmetrically distributed, including waste tire counterweights, steel piles and connecting brackets. The waste tire counterweights are formed by pouring reinforced concrete 2 inside the waste tires 1; the main body of the connecting brackets There are two main connecting plates 4 and two secondary connecting plates 6 perpendicular to each other, and suspension rings 10 are provided at the joints of the two main connecting plates 4, wherein supporting plates 7 are provided near both ends of the first main connecting plate 4 It is vertically connected to the two ends of the second main connecting plate 4 and the secondary connecting plate 6 with the bushing 8, the two ends of the two secondary connecting plates 6 are provided with a supporting plate 7 and the casing 8, and the upper parts of all the casings 8 Construction holes 9 are all set, and sleeves 12 are provided a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com