Assembled type anchoring system applicable to hard seabed

An anchoring system and assembly technology, applied in the field of anchoring systems, can solve the problems of small friction coefficient, limited anchoring force, and difficulty in fixing the cage system, and achieve the effect of strong anti-overturning ability and low center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

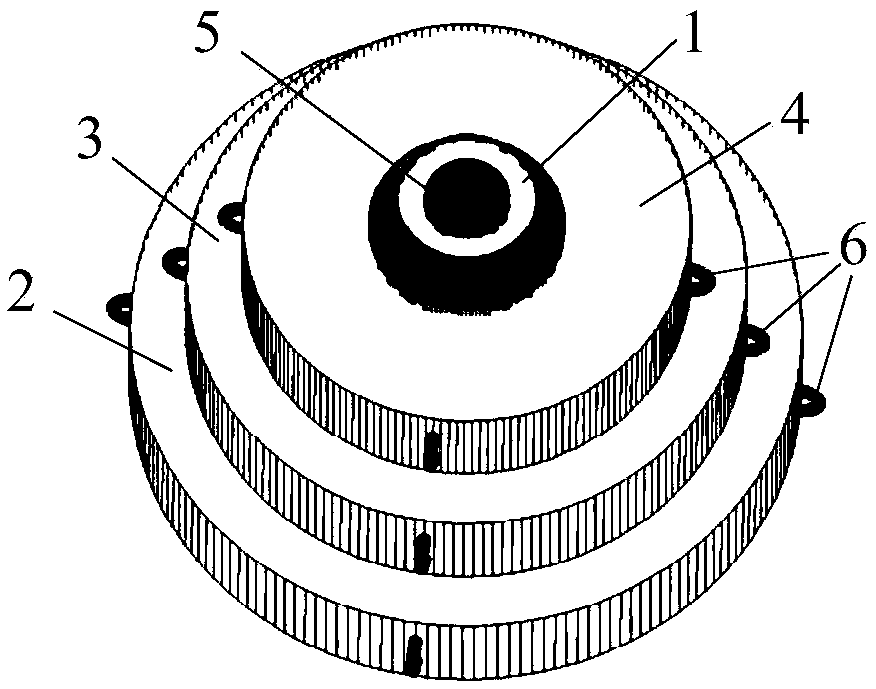

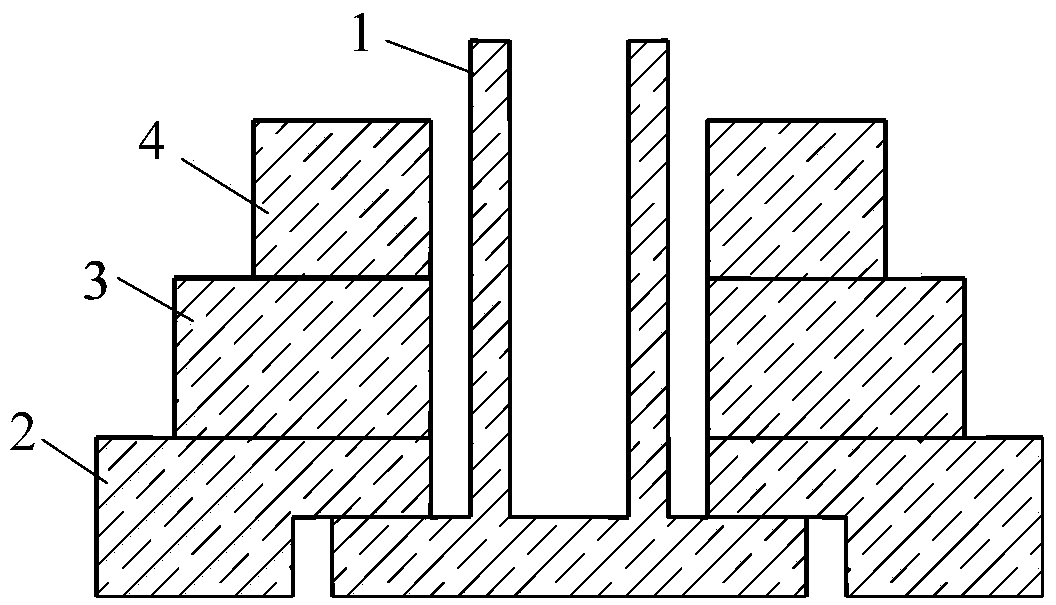

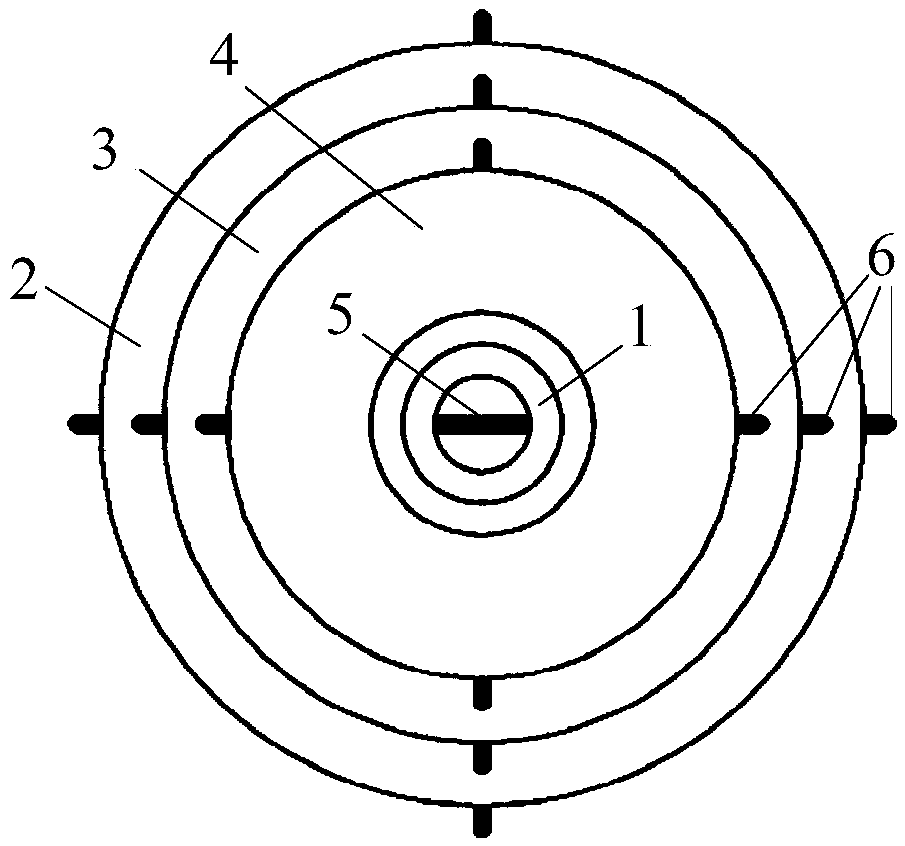

[0029] like Figure 1-7 As shown, the assembled anchoring system suitable for hard seabeds includes a cement anchor body 1, a first-level counterweight 2, a second-level counterweight 3, and a third-level counterweight. Block 4; the first-level counterweight 2 is set on the vertical cylinder of the cement anchor main body 1, and the second-level counterweight 3 is placed on the upper end surface of the first-level counterweight 2 and placed on the cement anchor main body 1 On the vertical cylinder of the cement anchor body 1, the third-level counterweight 4 is placed on the second-level counterweight 3 and sleeved on the vertical cylinder of the main body of the cement anchor 1 to form a whole anchoring system. The cement anchor main body 1 includes a lower solid cylindrical bottom plate and an upper vertical hollow cylinder, and the diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com